Roger Skoff writes about the stuff our stuff is made of...

Many years ago, Goldmund, one of Europe's leading manufacturers of reference-quality audio products, offered individual "Cube" amplifiers to plug into and directly power each of the sections of its then US$80,000 (more like US$500K, today) Apologue speaker system. Among the talking points for these amplifiers, which were an additional cost accessory, were the facts that their chassis were 24K gold-plated, inside and out, and that, "because so much of that precious metal was used in making them," their price was set to vary with the daily market price of gold.

Yup, really.

Two things about that strike me as interesting. The first is that, other than that gold is pretty and doesn't oxidize or corrode, I can think of no significant benefit of any kind from using gold plating on an electronic chassis. If the chassis were gold over copper, perhaps, instead of the usual aluminum, there might be some small grounding benefit, but that would more likely come from copper's greater conductivity/lower electrical resistance, as compared to aluminum, than because of gold's very slight comparative advantage over aluminum in those things. And even then, the gold's most significant benefits would just be to keep the copper from oxidizing and to make the Goldmund gear look as expensive as it really was.

The second point of interest also involves pricing. By varying the price of those amplifiers in accordance with the daily market price of gold, Goldmund—to the extent that people actually paid it—managed to declare and charge as if every part in the entire product (capacitors, resistors, transistors, diodes, transformers, circuit boards, chassis, face and connector plates, and everything else) were "worth its weight in gold."

In 1987, when the Goldmund Apologue was introduced, gold was valued at US$487.50 per Troy ounce (HERE or US$444.39 per "regular" ounce of weight HERE).

Putting it more properly in perspective, that works out to US$7110.24 per pound for every single part of the amplifier, including (if it had them) the little rubber feet on the bottom.

In the case of the gold-plating on the Goldmund Cubes (but not on connectors or electrical contact points, where, without protective plating, performance could suffer and constant cleaning would be needed), it's hard to find a performance advantage sufficient to justify the added price. And not—functionally—necessary gold isn't the only thing. There are other things, too, that High-End audio manufacturers use and charge for that do little or nothing to improve performance, but that can add considerably to what we pay for things. One of the most common of those is carbon fiber.

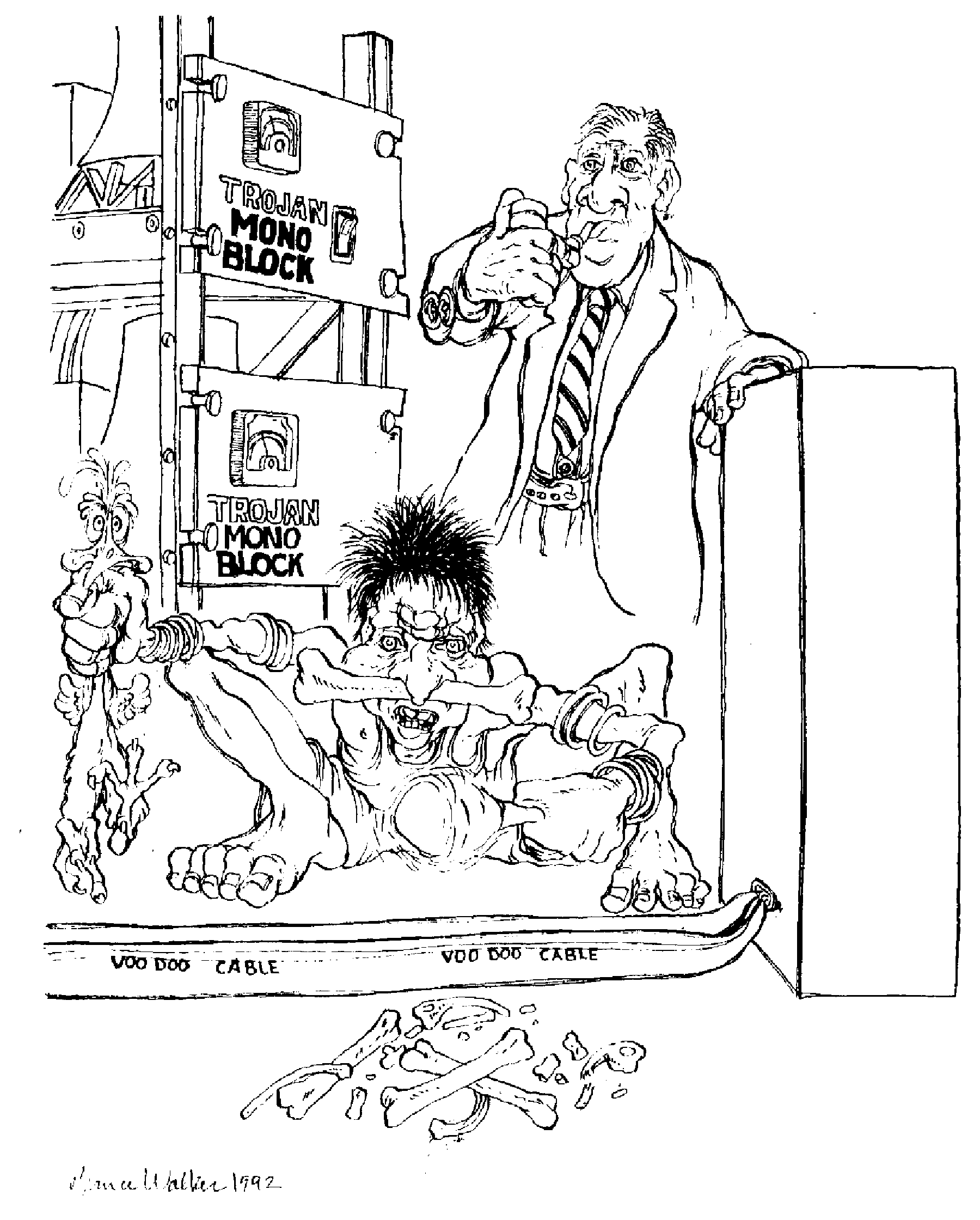

Like gold or other plating, carbon fiber is pretty and does offer certain practical advantages. Among other things, it's very light and very rigid, which makes it ideal for use in making the "wand" portion of a phono tonearm. Where it's used most, though, in High-End audio is on the "shells" of RCA connectors and fancy AC power connectors, where it's not part of any circuit and can have no material effect, dielectric or otherwise, on product performance. It's also used as the expensive but purely decorative material of choice for the cover of the "box" portion of those absurdly expensive speaker cables that look like huge, shiny, black snakes that have somehow swallowed, and are waiting to digest, what appears to be either a very small sports car or a fairly large roast turkey.

Other things, like ultra-pure copper, or exotic dielectric materials for cables, connectors, and capacitors, and the internal wiring for speakers and electronic components, to offer just a couple of examples, do provide real performance advantages to fully justify their extra cost. The problem, though, in this hobby where so many claims are unprovable except by subjective experience, lies in trying to determine which things those are, in order to take advantage of them.

And, strangely enough, there are still other things, materials, and finishes or styling features, that do nothing but look good and make products more expensive, but are still completely worth their price.

One perfect example of this is something that happened to me back in the 1980s, coincidentally around the same time as Goldmund bringing out the Apologue: One of the very best electronics designers our hobby has ever known had just brought out a new, very expensive for its time (well over US$5000) (sic), High-End power amplifier that not only sounded extraordinarily good, but that featured an utterly gorgeous ultra-heavy, titanium-finished, faceplate and rackmount handles, and that had deeply engraved logo and model identification.

The amp was magnificent looking, and when I told the designer so, his response was that it ought to be, considering that just the front panel and handles for each amplifier was costing him more than US$200—a figure that, at the time, could have bought a complete "name brand" 100-watt per channel receiver at full MSRP!

When I did a quick calculation and realized that just that one feature was adding—even at an entirely ordinary cost-to-price ratio—something in the range of US$1000 to each amplifier's MSRP, I asked him why he had done that. "Wouldn't you be better off; sell more units; and make more money if you had used an ordinary faceplate, logo, and handles, and set the price US$1000 cheaper?"

His response was something that I will never forget, and that I have been guided by to this day. "No; an expensive product needs to look expensive—preferably even more expensive than its actual price in order to appeal to its buyer. If I had just made this amplifier ordinary-looking and dropped the price, it would still have been expensive, but it wouldn't have looked the part, and I might not sell any units at all!"

Sometimes the very most important features don't do anything at all other than to just make you want to buy the product.

The next time you get the urge to add to or change your system, spend the time and effort to find out exactly what it is that you're buying, and how much each of all its "special" materials or features seems to be adding to what you have to pay for it. Then make your buying decision, always remembering that only you can ever properly judge what constitutes a material difference, and what's of value to you.