The importance of resonance and vibration control in allowing a high end audio system to perform at its very best is beyond debate. There may some holdouts in the audiophile community, but there are more than a few credible studies on the effects of resonance on electronic equipment in critical applications. The aerospace, military, and medical industries have long understood these effects on delicate instruments and are constantly pursuing solutions that can make an enormous difference.

Perfectionist audio hobbyists have experienced the effects of vibration on their audio systems going back to day one, when footfalls would cause the needle to jump on their record players. This would essentially provide a major obstacle to enjoying music. As things progressed, turntable manufacturers started to address some of these issues by creating bases out of different materials and experimenting with a wide variety of theories and application.

Going back just a few decades, many speaker manufacturers have attempted to uncover every stone to try to control or "tame" cabinet resonances. Methods used have been everything from separate chambers for each driver, bracing, mass loading, and using incredibly rigid material as opposed to MDF. There has also been the implementation of spikes and plinths to decouple speakers from the floor.

We now have a very healthy market for vibration/resonance control devices and racks for high performance audio, with different manufacturers each applying a particular methodology. A reason why these devices probably became far more important in recent times is the fact that audiophiles have demanded higher and higher sound pressure levels with the lowest possible distortion. This means that designers have incorporated bigger and beefier power supplies in amplifiers, and far more circuitry to include microprocessors, which means more elaborate case work. This all means more parts and mass to resonate. This is not to mention that there are now speakers capable of pressurizing a room like never before, and they can plumb the depths of the deepest bass notes; which will provide even more airborne vibration.

There are a number of vendors addressing the issues above. One such company is Symposium Acoustics, and they are the subject of this write up. Symposium is based in Pompton Lakes, NJ, and is headed up by the rather mercurial Peter Bizlewicz. I asked Peter about his background, his experiences in high end audio, and how ultimately that led to the forming of Symposium.

Peter generously offered up the following...

As an inquisitive child I had both a fascination with science and also a love of music. During my high school years, I was introduced to high end audio by a neighbor who owned state-of-the-art audio equipment. I couldn't afford a good stereo, but he was kind enough to allow me to play my cherished Beatles albums to hear what they "really" sounded like. That was it; I was hooked.

My interest in science continued, and after winning a competitive, four year engineering scholarship to MIT, an epiphany made me abandon Cambridge for a different curriculum and another life path altogether - or so I thought. After a few more years and almost as many colleges, I wound up with a degree from NYU Film School, and began doing sound for independent films, television, and video projects.

Later, I was hired as a touring sound engineer for Broadway musicals. The experience of mixing live, acoustic instruments and human voice in scores of different venues all across the United States and Canada (which ran the gamut from gorgeous-sounding, beautiful old music palaces to converted sheet-metal aircraft hangars) night after night, and having to make it all seem as if there were no microphones or speakers being used, was the invaluable training that taught me the differences between natural acoustic sound and electro-mechanically reproduced sound. With the push of a slider, I was able to instantly hear the difference (in a real acoustic space and not a studio) between live sound by accomplished musicians and the same sound through a high quality sound reinforcement system, and I worked hard to minimize the differences.

My greatest compliments came when members of the audience were shocked to learn after a performance that there had been microphones on all the performers, and that the singing they had heard was coming through loudspeakers. This reinforced my belief that the purpose of technology is to make itself disappear; an axiom specifically apropos for high end audio, where the ends too often reveals the means. I have tried to apply these lessons to my inventions and my audio design philosophy.

My technical nature and audiophile life converged as an interest in loudspeaker design. While studying film production at NYU, I made my first commercial sales of audio equipment: custom loudspeakers to private owners and a Manhattan recording studio. Years later, I first heard of the concept of vibration control when a friend who was working as an audio salesman told me that someone had come in to the store and claimed that when he placed his amplifier on a plank of MDF wood, the sound got better. It sounded like voodoo, and I tended not to believe it, but I tried it, and found that it DID make a difference. Not a lot, but something, and something positive.

A little later, while visiting an audiophile friend in Los Angeles, I brought his ailing tubed amplifier to a repair station and while I was there, noticed one Audio Research amp that looked like it had been completely disassembled, with every circuit board, transformer, tube socket, etc. mounted on separate wood pieces. It looked like one of those science fair projects where the device that was being demonstrated had been exploded down to its component parts for educational purposes.

I asked the proprietor "what's the story with this amplifier" and he shook his head, looked sad, and reported that the owner was apparently some kind of nut who thought that the amplifier sounded better when all the parts were mounted like that. He shrugged and walked away, leaving me staring at the bizarre assemblage. When I recalled the report of the amplifier placed on the MDF board, the reason why someone may have been deranged enough to take apart an entire amplifier and mount it like that suddenly clicked and I began wondering if there was something to this vibration business after all. That is, one nut might simply be crazy, but two nuts with the same affliction, separated by an entire continent, suggests a real disease, and I decided that this disease, whatever it is, might deserve further inquiry.

Then one day, back at home working on some loudspeakers, as I put the phono cartridge back down onto the record, expecting to hear music, I heard nothing save for a very faint, tinny sound. I quickly realized that I had neglected to reconnect the speakers to the amplifier (!) and that's why there was no sound, but I was curious as to where the tinny sound was coming from. At first, I thought it was the phono stylus scratching its way through the record groove, but to my surprise, the sound was coming from my solid state amplifier! I took off the chassis top, and being careful not to get zapped, tried to localize the source of the music. Was it the power transformer? No - the sound was coming from, of all places, the heat sink fins. Suddenly, I realized that the source of the sound had to be the output MOSFET transistors. They were acting as tiny speakers, "singing" as current flowed through them, heating them up and thus expanding and contracting, and so creating vibration which ultimately propagated out through the cooling fins, making sound.

The connection between current and sound, while elementary, had been suddenly presented to me from a new perspective, however, and for some reason I somehow got the notion that perhaps vibration was a two-way affair. That is, if electrical current could effect (with an "e") vibration, why wouldn't vibration in turn affect (with an "a") electrical currents - and thus, signal quality? Two things occurred to me; first, that the truth was that vibratory energy (a considerable amount, enough to make sound) was being generated in the amplifier, by the amplifier itself, and second, that because of this link between critical signal junctions and vibration, it might be possible that vibration, whether internally or externally generated, could in turn affect signal quality, most likely for the worse.

And, if this was true, then it followed that if this energy could be eliminated or reduced, it might improve the electrical function of the amplifier itself, and so, improve the quality of reproduced sound. I thought that the way to investigate this might be to interface the amplifier with an absorptive engine that could dissipate these energies, and after reading some technical treatises about constrained layer damping, heat absorption, etc, and drawing upon my own insights into mechanical impedance matching, I assembled my first vibration-absorbing platforms and began experimenting with them under audio components. Soon thereafter, I was encouraged to offer these inventions as products, and the first Symposium platform was sold, through an audio dealer in Westchester, New York, in March of 1994. More ideas and products were to follow, but that was the beginning of Symposium Acoustics.

Initial Exposure

I have previously been a customer of Symposium having purchased at full retail multiple sets of their Rollerblock and Rollerblock Jr. products several years ago. These purchases were made based on strong recommendations from audiophile friends. To be quite honest, I was quite neutral in regards to this product category, until I installed them. I never thought much about how they worked, but they did. I used them under sources and amplification. They made a substantial impact on my system in several key areas and made me a very happy camper. I had several audiophiles rave about other Symposium products, like their racks and shelves, but I had reached budgetary limitations and was quite happy with my system at that point and the improvements I heard.

Fast forward in time, and our esteemed editor contacted me about an opportunity to review several Symposium products. I mentioned my previous experience and familiarity with the line. Peter contacted me and we decided that Symposium shelves would be the perfect product category for a review in my system.

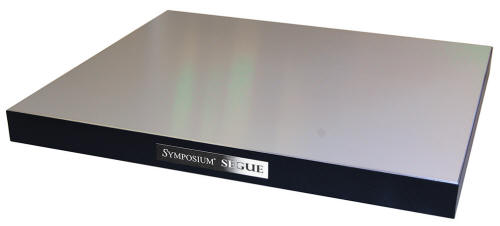

Peter shipped to me a total of four shelves. We had several discussions beforehand to as we the Segue wanted to make sure all my gear was matched to the right product with considerations to sizing. I received one sample each of the Svelte Shelf, the Svelte Plus, The Segue, and the Segue ISO. All are beautifully made, and easily integrate into any system. The Svelte Shelf pricing starts at $199 for an 8 x 10 unit, the smallest the may make. The 19 x 14 sample I received sells for $399, the Svelte Plus starts at $299 for an 8 x 10, the 19 x 4 I was sent sells for $499, and the Segue platforms start at $199 for the 19 x 14 size. Symposium Precision Couplers are extra if needed.

The Svelte Shelf is one of Symposium's most popular products and there is a lot of technology going on here. Rather than give readers a cherry picked laundry list of proprietary design factors, I would strongly suggest clicking here. All manufacturers should supply this kind of detailed information with their products. Symposium is rather unique in this.

The Segue and Segue ISO are actually some of Symposium's newer products. According to Peter, "the Segue and Segue ISO are distinct products, similar in contradistinction to the Svelte and Svelte Plus in that the latter type is an enhanced version of its seminal and more basic sibling. (The Segue ISO adds extreme low frequency vertical isolation to the Segue engine, and was specifically intended for use with analog turntables [although they can be successfully used with virtually any type of component]). The extra cost is due to the isolation suspension system of the ISO and its distinctive, dual-strip edgebanding."

The Segue was designed to be an affordable & effective entry level platform. The Segue ISO is a distinct version of the standard Segue, and according to Peter, "the footers are actually an arrangement of five precision, stainless steel conical springs internally damped with special air-cell foam. They have a very linear compression coefficient over their entire compression range, and are superior to normal springs, since this design gives them linear reaction to vertical wave displacement, very low self resonance, and damped transient recovery (that is, little or no "bounce")." The Segue starts at $199 MSRP for the 19 x 14 size and the Segue ISO starts at $349 for the 19 x 14 size.

Setup and Methodology

There are a few basic guidelines when using Symposium shelves. First, any component with rubbery, sorbothane feet is no no. Symposium says you can use Precision Couplers, Rollerblocks, or any other device of your choice as long as it is a hard coupling device and not a soft or compliant footer.

I found this of particular note: Peter told me "our rigid platforms have NO (practical) weight considerations; The only platform in our line that has a weight limit is the Segue ISO, because of the Segue ISO's vertical suspension system which is optimized or "tuned" for a given weight range. The Segue ISO LD (what you received) ["light duty"] version load limit is about 40 pounds; the MD ["medium duty"] version load range is approximately 40 - 80 pounds, although we can make them for higher weight loads. This is the only product so annotated in our platform line. As a footnote, the standard Svelte, Svelte Plus or Segue (or even the Ultra and Super Plus) in the standard 19x14 size all have a theoretical weight limit in the realm of about 3900 pounds (yes- two tons, evenly distributed!), and so, can be practically ignored."

I decided to take a modular approach for this review for a number of reasons. First, I want to hear what each shelf was doing, implemented one at a time. I had a number of components, especially amplifiers, come through the system during this review period. This gave me the opportunity to hear what the shelves were doing across several system configurations. I started first with a Svelte Shelf Plus underneath a pair of Merrill Audio Thor solid-state monoblock amplifiers. They are rather compact, and weigh a combined 15 Lbs. They both fit on the one shelf perfectly. Interestingly, they are outfitted in the factory with aftermarket footers from one of Symposium's competitors.

I had the Thors in the system for a good three weeks before the Symposium samples arrived so I had a very good idea how they sounded. The Thors placed on the Svelte Plus produced a clearly superior result in a few areas. First, imaging was more specific, and this in turn, allowed for an ever more defined soundstage, something these amps were already doing very well.

Another area I noticed an immediate and clear improvement in was bass articulation. The Thors were producing superb, fight, and deep bass, but on the Svelte Shelf Plus, bass notes were more precise, with less, if any, overhang. The entire spectrum from mid bass on down benefited from a tighter overall picture.

After the Thors went back to the factory, I then used my own Audio Research VS55 KT120 based tube amp. I used my Rollerblock Juniors underneath the ARC in conjunction with the shelves, and with every other amp as well. My feeling is that tube amps are tailor made for Symposium products. The physical nature of tube amps means that there is quite a bit of mechanical issues going on. Vibrating transformers, tubes, and power supplies all contribute something, and as Peter noted, probably nothing positive.

The ARC on the Svelte Plus benefitted in most of the areas the Thors did. The amp seemed to be better in all the areas it excels in. That being midrange liquidity, top end smoothness, and overall purity. Bass articulation is not the amps very best asset, but this improved dramatically sitting atop the Symposium shelf.

My findings were duplicated with the Bob Carver Black Magic EL84M based tube amp as well. A much smaller amp, at about half the weight of the ARC's 35 Lbs, it still has those transformers and glass. It is an amazingly sweet sounding amp, and it strength is clearly in its ultra pure midrange. I really did not think it would improve by such a wide margin on the Svelte Plus, but it did.

The last two amplifiers I used were both solid state. The first being the CLONES Audio 25p power amplifier, and the Roksan Kandy A2 integrated. The CLONES is wonderful product that only gives up a little refinement to much more costly amps. The Roksan is buttery smooth and is a heck of a bargain at around $1900. Both amps produced a wider soundstage and a more transparent midrange on the Symposium shelf. By this stage, I was no longer surprised.

Perhaps the place I have always made using resonance control a priority are my digital sources. I heard the biggest improvement in my system several years ago with my Naim CD players, before I went with a network server, by placing Rollerblock Juniors underneath them. This was a real eye opener, considering Naim use a clever disc clamping mechanism.

I continue the tradition of controlling resonances on my digital sources by placing Rollerblock Juniors underneath both the Bryston BDA-1 DAC and the Simaudio Neo 380D DAC with built in MiND streamer. The NEO 380D was the next place I used a shelf, and it was a Svelte Shelf to be exact, coupled with the Rollerblocks. Interestingly, the same places I noticed the biggest improvements I heard with the disc spinners, were the same with the DAC. That was more refined and sophisticated high frequency reproduction.

The final two areas to get the Symposium treatment were my Musical Fidelity M1 CDT transport, and my Audience adeptResponse power conditioner. I used the Segue ISO under the transport, coupled with standard Rollerblocks, which I connect via AES/EBU to the Simaudio DAC, and the Segue under the conditioner using the three supplied Precision Couplers, since the Audience has sorbothane feet.

The Musical Fidelity offered up an overall more refined picture, very similar to what I first heard with my Naim players, although the CDT is a slot loader. Actually it even made disc playback very difficult to distinguish from file playback via the network. With the conditioner, there came a point of diminishing returns. I had a hard time deciding if there was any improvement. It would probably be lower on list of priorities with respect to resonance control in the end, although in systems closer to the state of the art, improvements may be easier to find.

A final twist. I used the Segue ISO underneath a series of vintage reel to reel decks, as I have started a project where I am dubbing high quality, classic 7.5 ips pre-recorded tapes to 192kHz 24-bit and DSD digital. My decks include a Sony 350, a Sony 530, and Revox A77. There was an improvement in the overall presentation and the digital master, as monitored via headphones. I can't imagine recording studios not benefiting.

It should be noted that Symposium also highly touts the effects of their products under speakers. I did not attempt to use any of the shelves in my set up, but I know several customers who have and raved. Your mileage of course will vary depending on your particular set up. On stand mount monitors I think it would be a no brainer with respect to an improvement in imaging.

Conclusion

Symposium Acoustics has made it clear to me that their suite of products is essential to maximizing the potential of any high end system. The company is not the flavor of the month, and they have continually looked to improve their products with an intelligent approach with the intention of solving real world problems, with proven theory, and experimentation.

The Symposium product line up is varied, and it should not be difficult to find the solutions that are appropriate for your system. Even those with modest budgets can dip their toes in the water, as I did, several years ago. On the other end, the flagship ISIS rack is a thing to behold. The products under review here, the Svelte Shelf, Svelte Plus, The Segue and the Segue ISO platforms, are home runs. I can't recommend them highly enough for a variety of applications. Andre Marc

Symposium

www.symposiumusa.com

Q&A with Peter Bizlewicz of Symposium Acoustics

PF: Can you tell us a bit about the manufacturing process of the various products?

PB: All Symposium products have multiple manufacturing, finishing and assembly stages which are critical to performance; some products are 100% made in-house at our factory in Pompton Lakes, NJ; some products go through multiple phases of manufacturing, with some stages done in our shop and others performed elsewhere. For instance, some products have laser-cut stainless steel parts; the cutting laser needed to cut the heavy gauge stainless steel we use costs about a million dollars and takes up the space of a basketball court. Unfortunately, we don't have one of those, and I wouldn't know where to put it if we did! However, all product, regardless of complexity of manufacture, is assembled, tested, finished, packed and shipped from our facility in Pompton Lakes.

We do as much as we can in-house as feasible, but if a subcontractor can do a certain part better than we can for a reasonable price, we will have it made there. Our standards are high, though, and it's a constant struggle to make sure that things are done right. I have watched a sad decline in general manufacturing quality of many other products in recent decades; at the very least, we at Symposium can resolve not to be another member of this unfortunate trend. In our case, this is more than a cosmetic or "fit 'n finish" issue; the function of our products is purely analog in nature and are manipulating or interacting with physical processes (in other words, "it's not nice to fool Mother Nature!").

Of course, as any manufacturer does, we occasionally experience manufacturing flaws or problems. We take such problems quite seriously and work hard to correct them. Thus, in a very real sense, our products have evolved over the years to have improved reliability, finishing and precision, and I might mention that I still have the very first Symposium platform ever put together, and while it's showing its age, it's still in good functional condition and still works fine after more than twenty years.

PF: How do you sway remaining skeptics of the efficacy of resonance control, or what ever name we give it, in high performance domestic audio set ups?

PB: I don't worry about potential members of the Flat Earth Society who may have a problem with the more advanced aspects of high end audio, and this includes vibration control. Ultimately and unfortunately, it's their loss. The world has a generous supply of skeptics who seem compelled to mask ignorance with sophistry. The irony is that the usual modus operandi of these types is to accuse the audiophile community of sophistry, but the reverse is usually true: the casual skeptic has not done any research, and we have.

The first year I did CES, I had a small table set up with a CD player and I was doing demonstrations of the improvements in sound quality, through headphones, by placing the CD player up on Rollerblocks and a platform. When you physically demonstrate something, that is science, and we made a lot of believers with that simple setup. One very technical-looking fellow (who seemed a bit lost in the high performance audio area) was hurrying through the aisle of high end accessories, doing his very best not to make eye contact with any of the audio lunatics (such as myself) occupying the tables on either side. As he rushed past, I called to him "How about a demonstration?" Without changing his gait, he almost shouted, "I'll believe it when I can see it on an oscilloscope!" I thought, what does looking at an oscilloscope trace have to do with listening?

I understand his perspective; such "tech heads" (I have also been called one of these) have been formally trained that nothing exists that cannot be quantified or defined (I am not speaking of mathematical theory here such as Gödelian Incompleteness Theory or Randomness, I'm referring to so called "real" phenomena). However, the greater reality is that this position assumes that everything is known. Unfortunately (or fortunately), everything is NOT known, and therefore, if something is perceived, but is not or cannot (yet) be quantified, it doesn't necessarily mean it is not real. If more than one person perceives the same phenomena under repeatable and controlled conditions, it is either a case of mass hallucination or it is a real natural phenomenon. Ruling out the former, such phenomena may be quantified or defined tomorrow or in a hundred years, but to state that until that time it does not exist because we don't know how to measure it yet is neither logical, scientific, nor intelligent.

My 8th grade science teacher burned into me that there was no substitute for empirical investigation in the pursuit of science. He taught me that theory was a nice place to start, but in order to really learn the truth about something you must do experiments and scientifically and empirically determine what is true and what is not. Translation: get off your butt and try it! This is how knowledge is increased, not by saying "no," but by saying "maybe." Those who reject concepts like vibration control out of hand from some preconceived viewpoint are making the same "lofty" mistake that Aristotle did when he proclaimed that a five pound weight would fall five times faster than a one pound weight. It took a fellow named Galileo to demonstrate that they both fell at the same rate, something that the "learned" masters had dutifully taught their students for over a thousand years until one person decided to "see for himself." (Of course, Galileo was eventually thrown into the hoosegow for such "heresies.")

The fact that this "law" had been taken for granted and never put to the test for thousands of years should serve as a warning against our tendency to make assumptions based on prejudicial inference - that is, from one's uninformed opinion. Intuition is valuable and may lead us in a direction, but finally, it is only direct experience that teaches. But there's another aspect to this, too: many so-called audio skeptics quite simply aren't audiophiles. Some people, as difficult as it may be for us to fathom, don't care about music or better sound and won't hear what is literally "right before their ears." Is it because they refuse to allow themselves to enjoy better sound? That's a question beyond my purview, and probably best left for the psychiatrists.

The writer William S. Burroughs once wrote a response to his good friend, poet Alan Ginsberg, who had asked Burroughs why he hadn't dissuaded him beforehand against doing something that resulted in an unpleasant experience for Ginsberg. Burroughs, older and wiser, simply replied that he didn't say anything because "you can't tell anybody anything they don't already know." That's putting it rather in the extreme, but it's another way of saying that some people just don't get it and never will.

I find it telling to have observed over and over that even open-minded people who are not audiophiles can easily hear the improvements that good vibration control can bring, and the people who seem to appreciate our products most are those who experience the most enjoyment from listening to their music systems. It has followed that, if a reasonably skeptical person is truly interested in better sound (and remember that not everyone cares!), the best way to sway that person who is "on the fence" is to let them try one of our products in a critical stage in their audio/music systems. We've made many believers out of skeptics this way, and judging by the whoops and hollers of some of the responses, some of the reactions have been akin to religious experiences. But perhaps, in our small and too-often misunderstood corner of the audio industry, we don't just offer products: now and then, we hand out epiphanies.