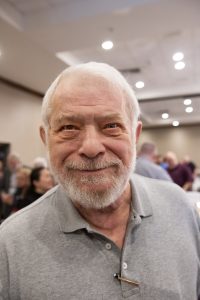

Roger Skoff writes about the things we buy

Did you know that if you drive a Mercedes-Benz, or a Toyota there's a good possibility that your car wasn't made in either Germany or Japan? It's true; to avoid taxes and duties, to save shipping costs, or even to ensure greater safety, higher quality, lower cost, or greater compliance with US law, many seemingly foreign car models are actually made in the United States.

It's the same thing the other way and with other products, too. For any number of reasons, including the ones just listed and more, many of the things we buy—especially in High End audio—are neither made by the company whose brand they bear nor even manufactured in that company's home country.

I found out about that for the first time in 1991, when I started my first High-End cable company, XLO.

When XLO first started, I wanted every part of the cables we built to be "Made in USA." The fact of it, though, was that, although we could have speaker connectors custom made to our specifications by an American company, there were no American-made RCA connectors available good enough to use on our interconnects.

The Japanese Mogami RCA connectors, however, were a brilliant design, using a unique air-space dielectric unlike anything else, either before or since, so we used them for as long as they remained available. Unfortunately, because their design was unusually complex, costly to build, and hard to assemble, Mogami finally stopped producing them.

Because they were so good, however, Mogami's US distributor, Marshall Electronics, wanted to be able to continue to supply them and sought out, and ultimately engaged, a Chinese manufacturer to continue production.

The "new" Mogami RCAs, though, were nowhere near as good or as good-sounding as the original ones and, because of truly terrible quality control, we (XLO) were finally forced to stop using them. And Marshall Electronics—after refunding our money for an entire bad batch—discontinued them, too.

That left us with the problem of having an active and fast-growing cable business and no source of RCA connectors good enough to use on our products. To solve that problem, I designed my own connectors, embodying all I could learn about what was necessary to provide the very best performance and, still wanting XLO to be all "Made In USA," turned to the best US manufacturers to have them built.

What I found in every instance was that:

- they would not do custom designs;

- they did not have or use the materials I wanted; OR

- they would do custom designs and would use custom materials but;

- had impossible minimum order requirements;

- were impossibly expensive;

- had impossibly long lead times; or

- any combination or all of the above.

So, because the Internet, back then, wasn't nearly as all-inclusive as it is now, I looked to Global Sources, a print-on-paper international electronics trade publication, to try to find a foreign source of supply.

That was where I learned that Taiwan had literally dozens of hi-fi connector manufacturers who seemed able to build what I wanted, and I sent off catalog requests to all of the ones that looked promising.

When they came, I was surprised to find that, although I had gotten many catalogs from many companies, they were all essentially identical. All of them had the same cover, the same graphics, and mostly the same products, (RCA connectors, XLRs, and various speaker connectors), described in mostly the same words and shown in mostly the same pictures. They did have different company names and contact information, though, and there were some few real product differences.

Faced with that, the only way I could think of to make a choice and to determine which of all of those companies I should engage to custom manufacture products to exactly my specifications, using exactly my specified designs and materials, was to actually fly there and meet with them.

I did that and, in meeting with people from the companies that I had contacted, I learned that the Taiwanese connector business was almost nothing like what I had expected it to be.

The truth was that, although all of those companies (and even more) claimed to be fully-equipped, broad-product-line, manufacturers, the products in the catalogs were mostly the cooperative efforts of a number of companies—one making an RCA connector's center pin, for example, another making its ground ring, another its shell, still another its rubber or plastic strain relief, and so on—with mostly everything being everybody using everybody else's parts to come up with a full multi-product product line.

There were some products actually made-all-the-way-through by a single company, but they were the exception, and not the rule.

Ultimately, after a week of interviewing potential manufacturers and visiting their factories, I was able to satisfy myself that what would be made for me would be made by just the single company that I gave the contract to, but even that contract allowed for specific-part exceptions for certain types of connectors for particular lines of XLO cables.

Now, nearly thirty years later—not only in Taiwan, but throughout much of Asia—things seem to have remained very much the same, and it's still virtually impossible with some products to figure out who it was that actually made them.

For one thing, there's a great deal of outright counterfeiting, with popular products being copied and reproduced down to the smallest visible detail by companies other than the one that the marked brand name indicates. This is particularly true for cables and connectors, which may look like "the real thing" but may be made from entirely different materials, or with different internal construction.

The other side of that, though, is a growing trend, whether for reason of parts availability, of convenience, or simply because another company may be able to do the same thing better or cheaper than they can do it themselves, for many of the real brand name companies to have genuine products sub-contracted out for others to build—just exactly as I did with connectors for XLO.

This is particularly true post-COVID, and a large part of it may have to do with supply-chain issues either caused by or remaining after the pandemic. My own new cable company, RSX, is a good example. We've been working for the last several months to bring out new products and accessories and, as before with XLO, we've found that keeping all of our sources within the United States is simply no longer possible.

Whether it's ultra-pure metals, exotic high-performance dielectric materials, or even just a particular machine needed for one specific manufacturing function, it's far more difficult now than it was even just a few years ago to find all of everything needed for quality production in one place, or even one country.

Whether that's good or bad, overall, is hard to say. Certainly, where things are only possible, or quality can be improved, or price held down by bringing together the best work of a number of specialist companies, wherever they might be, I'm all for it, and you should be too. If the result, though, is counterfeiting or any other deceptive practice, I'm not. The one thing I know for sure is that, for more and more products, it's getting harder all the time to know "Who made that?"

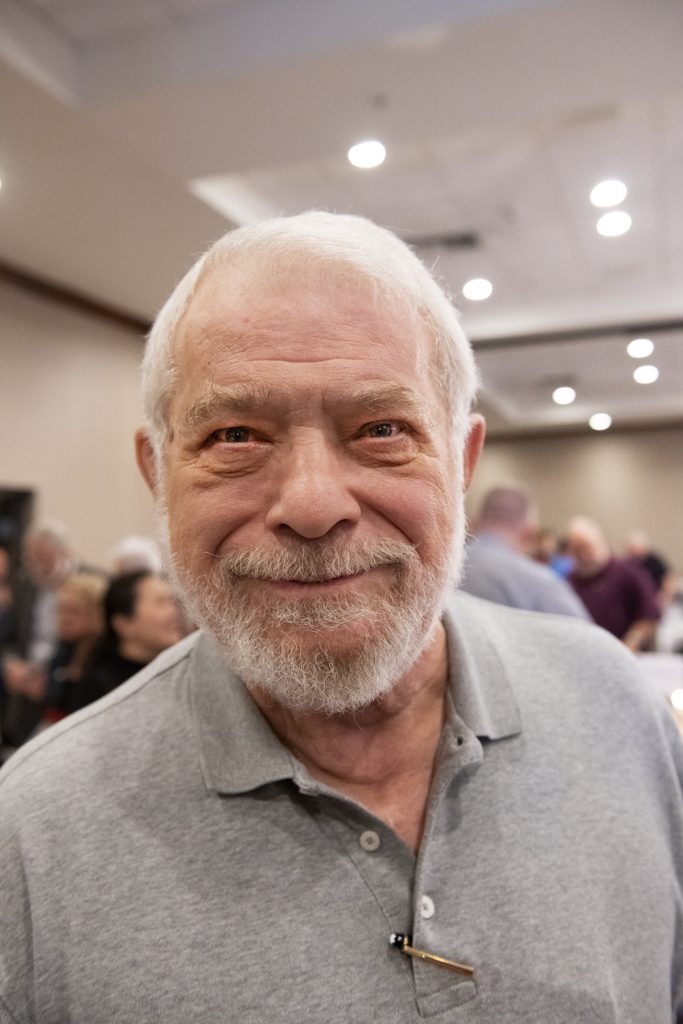

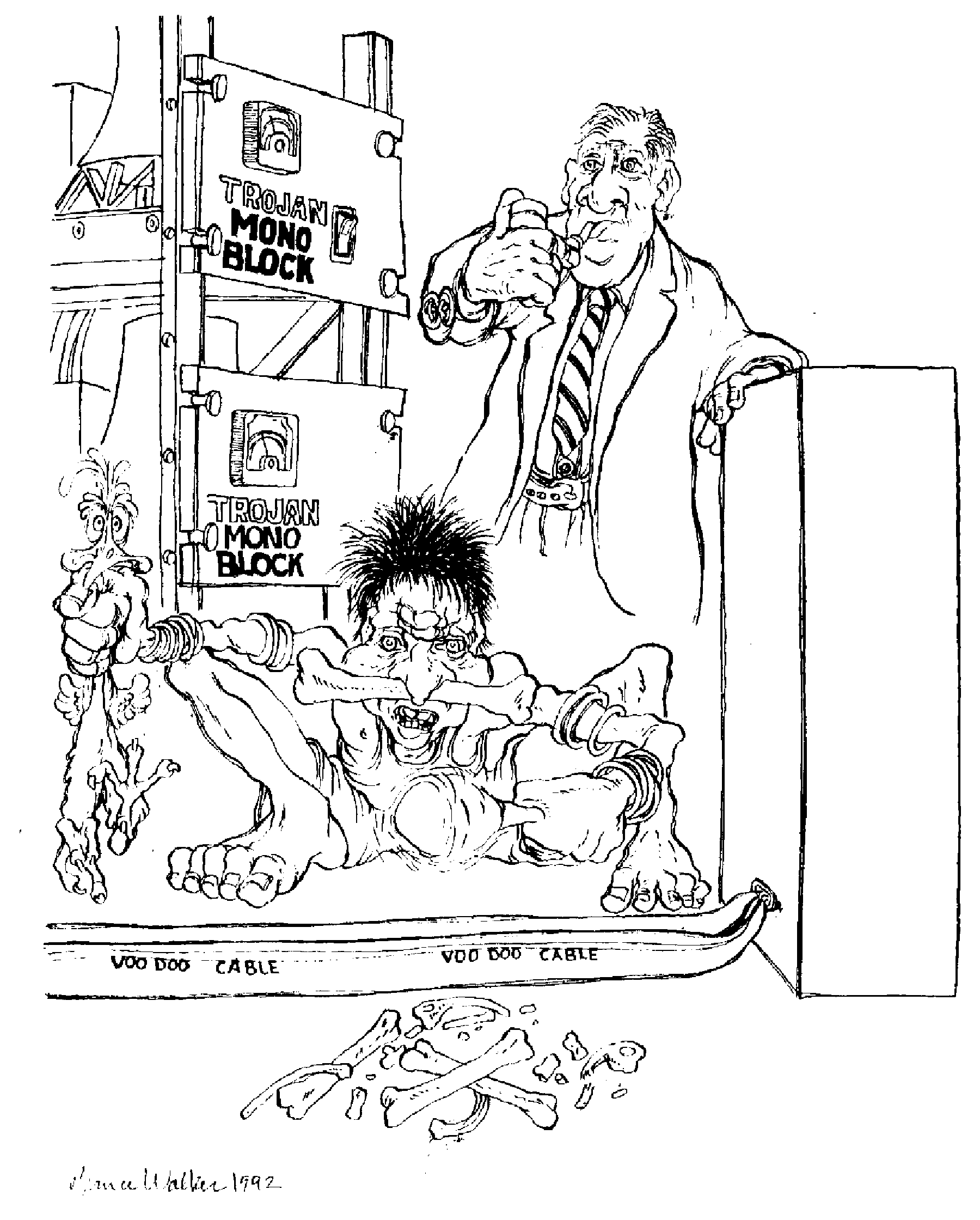

Photograph by David W. Robinson; drawings by Bruce Walker.