Norman Varney of AV RoomService Ltd. has joined Positive Feedback as a Senior Technical Editor as of Issue 113. His expertise in his field of audio acoustics and experience in the field makes him a helpful voice in our creative community for the audio arts. As has been our wont from the beginning of PF, we do welcome contributions from qualified voices in the high-end audio industry, provided that they don't use the opportunity to market their own products/attack competitors and others...which we simply don't allow here.

I have been working professionally in both the sound and vibration, and consumer electronics industries for decades. As an acoustical engineer and manufacturer of mechanical vibration isolation products, I feel compelled to address the misconceptions of incorporating spikes (or any rigid materials) with loudspeakers and/or other audio equipment. These misconceptions do not exist in the sound and vibration industries, and are very rare in the pro audio world, however they are very prevalent in the audiophile world.

There are many physical, acoustical, and perceptual disciplines involved here- we are only going to address the primary ones, and in only a general way, meaning we won't discuss the secondary or additional attributes that may come into play. There are some key concepts of physics to be applied. Many of them have been misapplied, misrepresented, or even made up and given as fact to you, the audiophile over the years. Let's clear these notions up. We won't discuss objective vs. subjective analysis, we'll just keep to basic, fundamental physics (in a simplistic, relatable form) that can be backed up by most any text book on mechanical or architectural acoustics. Note that I may use the term ‘spikes' interchangeably while refereeing to any rigid material device. Spikes are rigid devices, they just contact with a sharp point.

Misconception 1 - Spikes Isolate

No. Spikes or any other rigid material that is in contact with both the vibrating source and the receiving resting platform will act as a very effective conduit. Spikes couple. There are two ways that mechanical vibration isolation is applied- by breaking the vibration pathway, or by converting the mechanical energy into thermal energy via an appropriate resilient support material.

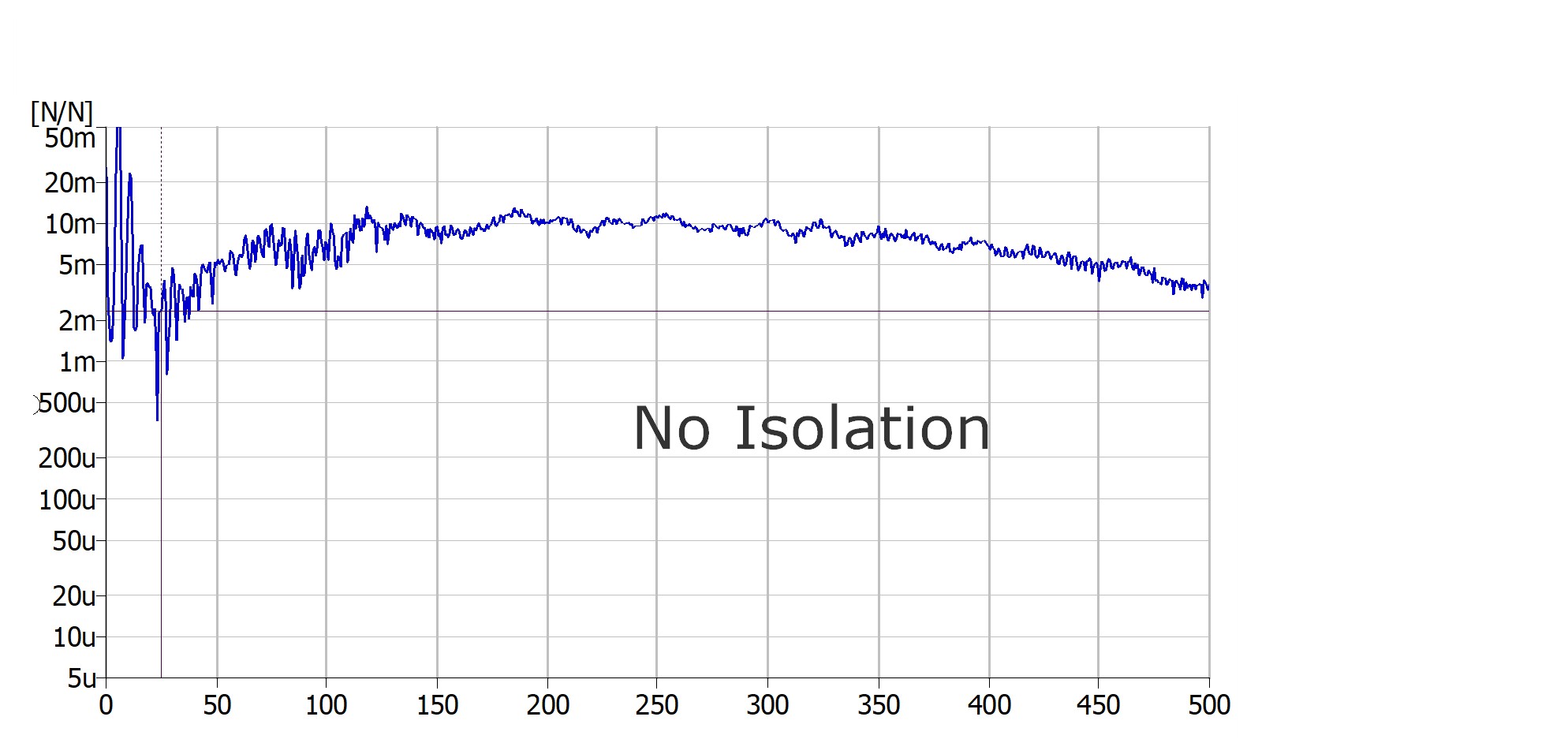

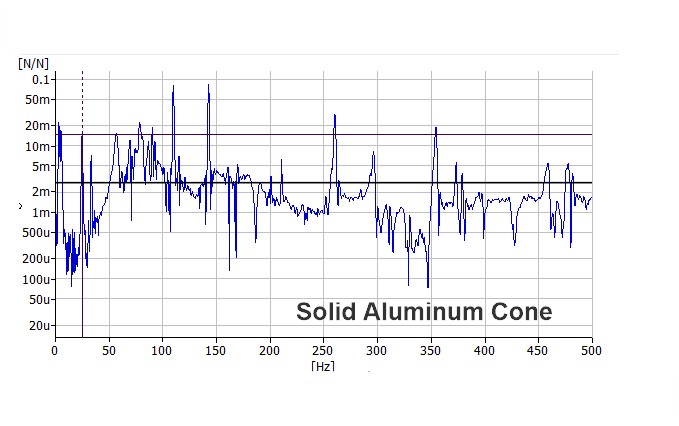

Looking at the lab test results below using the impulse hammer vibration transmissibility method, it is clear that not only do rigid feet NOT isolate, they amplify at their resonant frequencies. Each will act as a unique filter attenuating some frequencies and amplifying others. This is why rigid couplers sound different, and will vary with every different scenario. Note that different and louder does not necessarily mean more accurate. Note also that in the real world, the resting platform and its structural system will also interact with the couplers by adding more constructive and destructive interference. Couplers are unpredictable, inconsistent and never neutral. A quality audio isolation device will have no resonance in the audio bandwidth. When properly applied, it will perform predictably, consistently and neutral in every scenario.

Experiment 1

An easy experiment can be performed. Operate a music box mechanism (no box) or a tuning fork and make contact with any hard surface and hear that surface become a sounding board. The vibrations of the tines are being transferred to the surface and that surface is playing back into the room as a much louder secondary sound source.

Now experiment with placing a rigid audio equipment foot between the music box mechanism or tuning fork and the hard surface. Likely it will be as loud, but may sound a little different tonally. This is because every rigid material has unique resonances dependent on its material density, size, shape, load, and the interaction of the same characteristics with the associated contact surfaces. If you do not have any rigid audio feet, see my video demo HERE.

Now experiment with a sponge between the sound source and the hard surface. No doubt, it will be much softer in amplitude with the resilient material in place due to decoupling. Now you know, spikes transfer energy.

Misconception 2 - Spikes Transfer Energy In Only One Direction

Nope. We just proved that rigid contacts transfer vibration very efficiently. If sound vibrations can travel one direction, they can also travel the other. It's a free flowing two-way street. In addition, vibrations from the source can feedback (reflect) to the source from the resting platform, and the coupler itself. Cool, huh?

Some rigid feet, like cones, may sound different when inverted. This has nothing to do with directional transfer, rather with altered damping of the different top and bottom contact surfaces.

Misconception 3 - Spikes Drain Energy

The idea is this: "The vibrations of the loudspeaker cabinet are deformed by its own resonances, which are transmitted back to the membrane of the loudspeaker and induce distortions.

So, rather than imprisoning the vibrations in the cabinet, we evacuate them out of the enclosure and direct them elsewhere. It is easier to evacuate the vibratory energy towards a heavy mass connected to the lighter enclosure."

I believe the concept is that of an inertia block. This is where the vibration source is in direct contact with a heavy (at least 3X the weight of the source), rigid block (usually concrete). The idea is that if you make contact with something much more massive, that the energy will be dissipated into it. Like a drain in a sink, the energy just disappears and does not return. Well, it doesn't work that way. As we've discussed, to isolate vibrations, the path must be broken, or the energy converted. In this situation, the energy will transfer into the block, and into whatever the block is resting on. Remember that vibrations travel both directions, and they can reflect. In the case of an actual inertia block system, they always have isolators at their base. There are many applications for inertia block isolation, however audio equipment is not one of them. For audio equipment, isolators alone are all that's needed.

Experiment 2

As before, take a music box mechanism or tuning fork and find a slab floor over grade. Activate the device and make contact with the slab. Note how much energy is once again amplified when in contact with the massive slab, which is in contact with the massive planet Earth.

As we now understand, rigid feet are couplers and they communicate vibrations efficiently. Coupling two elements allow energy to flow freely between them. Coupling from light weight to heavy does not dissipate the energy. The idea that decoupling "imprisons" and that coupling "evacuates" vibrations is false. Unless the vibration path is broken, or the energy converted, vibrations will be transmitted. The coupler is precisely that, a coupler, which transmits both directions, and even reflects and amplifies. So, the concept does not attenuate original cabinet vibrations. Introducing couplers or decouplers will not alter the internally generated resonances of the enclosure.

Misconception 4 - A Small Contact Area Means Less Transfer

Misconception 5 - Concentrating the Load to a Small Point Means Less Transfer

The theory that a smaller contact area will offer less vibration transfer can be true, as long as you are applying an appropriate isolator for the load. This does not apply to a case with rigid feet, and is exasperated with a spike where you concentrate the entire load to a tiny contact point of the surface.

Experiment 3

Take the music box mechanism or tuning fork and make contact with a hard surface like a tabletop or shelf and listen. Now apply more force and notice how the sound becomes greater. Try it on different surfaces and hear differences. Their different densities, sizes, shapes, fastenings, etc. alter the tone character, even when it is the pure tone of a tuning fork. With a spike, you are likely applying a force of many tons at the tip. The contact point is almost bonded together and will communicate very efficiently.

So both statements are false. When applying a non-resilient foot, making the contact area smaller applies more force and usually makes the soundboard more energetic.

Misconception 6 - Rigid Mounts Control Driver Phase

Not likely. The idea is that rigid mounting of the speaker cabinet to a heavy surface prevents the drivers from being displaced, which keeps phase constant or coherent. First, rigid feet do not offer control of any of the six degrees of freedom, so the cabinet can still move via its own natural resonances.

This is a good place to point out that loudspeaker manufacturers do all that they can to avoid unwanted vibrations. This involves material damping, bracing, fastening, isolation, etc., and as they are applied, the price reflects.

Second, the cone displacement of a loudspeaker may be as small as one micron (1/26,000th of an inch, or a fraction of spider silk), while the internal and external vibration influences on the cabinet are many times as great.

Remember, feet of any kind do not reduce internally generated cabinet movement, however decoupling feet will prevent external influence.

Misconception 7 - Loudspeaker Cabinets Don't Vibrate

Yes they do. If you think that ultra dense cabinets don't move, try the music box mechanism or tuning fork on such a cabinet and hear it move. I have a cabinet cast of concrete and yet, it performs as a soundboard very well. You can prove it to yourself with the vibrating test device; if it becomes louder when it makes contact, than the surface is moving. You can't see it. Its displacement is too small, and its velocity too fast for the unaided eye. You may be able feel it, and you can certainly hear it. For example, with a tuning fork of A440, the cabinet is oscillating 440 times per second, and the cabinet is moving a few billionths of a meter, while the sound is probably amplified around 25 dB SPL louder than without contact.

Misconception 8 - One Size Fits All

In the noise and vibration industry, this notion does not exist. To properly isolate using a resilient material there are two primary factors that must be calculated; a) The load. If the load (weight pressure) on the isolator is too much or too little, it cannot function properly. Its resistance or impedance is above or below its effective operating window. b) Resonant frequencies under load. The isolating device must not have a frequency resonance above the lowest desired frequency of isolation. In our audio case, at minimum, this means 20Hz. It can be helpful for footfalls and turntable feedback to be even lower.

Experiment 4

Using your vibration test device, a thick and dense sponge, and a tabletop, lightly rest the vibrating device on the sponge and gradually apply more force. If conditions are right, this experiment should show that the resiliency has varying points of mechanical impedance match and mismatch, where both the SPL and the frequency bandwidth are affected by the varying density of the sponge.

Different sizes, densities and natural resonant frequencies for different resilient materials mean one size CANNOT fit all. Should you encounter such a device, or one without an accredited acoustic lab report showing its vibration transmissibility, you should question its credibility.

Misconception 9 - You Can't Hear it

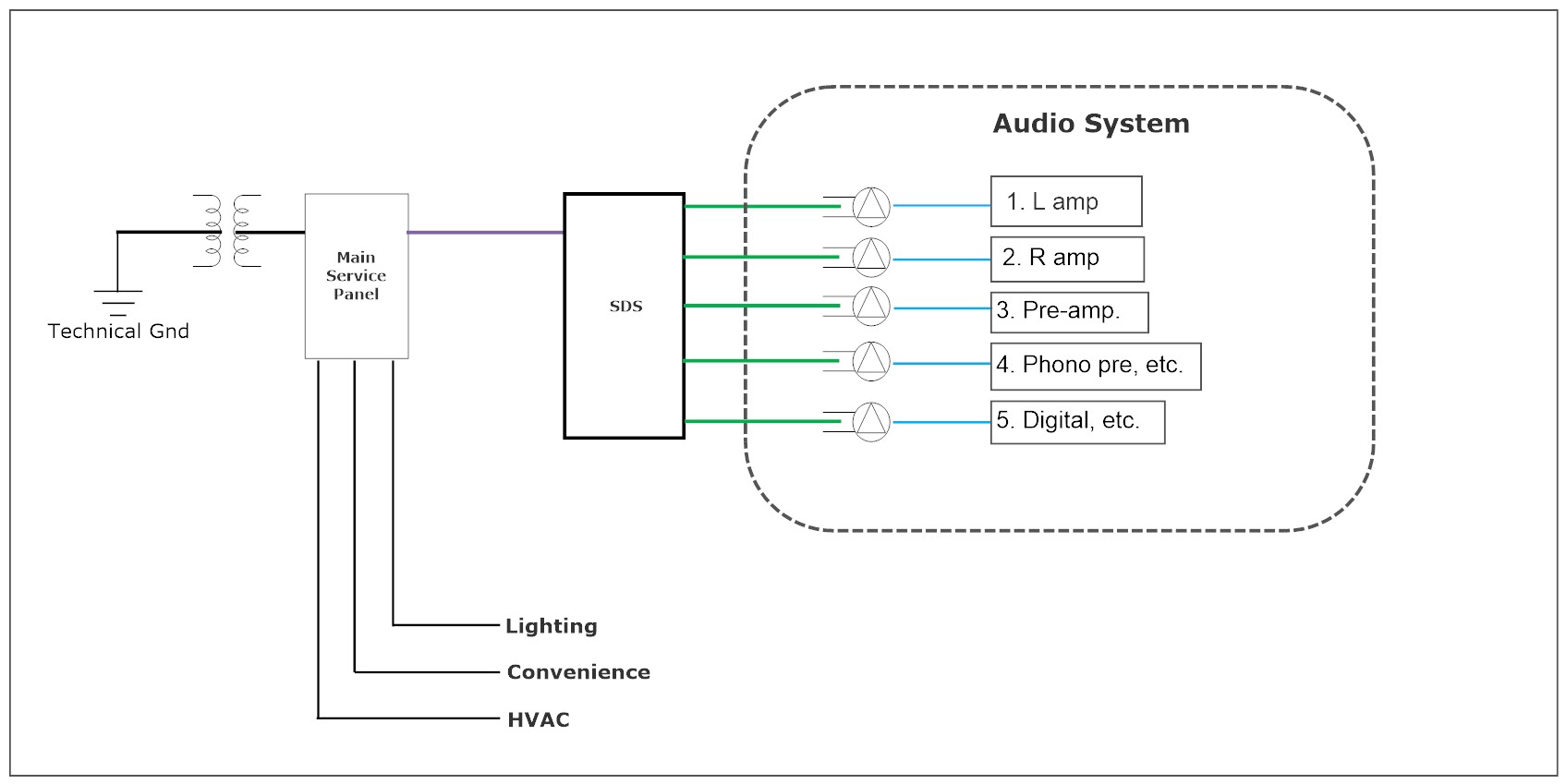

Yes you can. When you isolate a vibration source (speaker) from the building structure, the structure is quieted. Our buildings are mostly hard-fastened. This unbroken pathway is how the subwoofer is heard and felt in every room. The structure resonates. Structurally decoupling removes structural resonances, buzzes and rattles.

Experiment 5

Lightly fist-bump the wall cavity between studs. It will boom like a drum at about 70Hz. This is a mass/air/mass resonance, whose frequency is a function of the surface mass of the resilient skin (drywall) and the thickness of the airspace. When you play music containing 70Hz in it (just about all music will have 70Hz in it), the cavity will sympathize with it because the mechanical energy is connected. The wall now moves like an additional giant loudspeaker playing into the room. Multiply that with more wall cavities, floor cavities, ceiling cavities, and throw in some furnishings.

To go into further detail, each cavity acts as a capacitor, in that it stores the energy briefly and then releases it later in time, after the original airborne sound waves from the speakers have stopped. The floor, the ceiling, walls, furnishings can all be excited causing unwanted sound vibrations of resonances, buzzes and rattles. When the source of vibration (the loudspeaker) is isolated from the structure, only airborne sound waves from the speakers are heard. From an audiophile POV, dynamic range, low-level detail, tonality, spatiality, etc. are all improved. Everything becomes more articulate because the unwanted influences have been removed.

Lastly and briefly, controlling unwanted structural vibrations can mean better performing electronics. Mechanical vibrations can cause havoc to tubes, digital clocks, laser reading, stylus tracking, electrical contacts, etc.

Misconception 10 - You Can't Measure it

I see people all the time trying to measure different acoustical characteristics with the wrong tools, or the wrong application, and/or the wrong methods. However, limited measuring of vibration transmissibility (in very rough form) can be done by anyone with any smart phone and a few free apps. Note that this is only an indicator of vibration transfer/isolation and not a proper vibration transmissibility test.

Experiment 6, 7 and 8

You can measure the general amplitude of an audio foot with a music box mechanism in contact with the footer and a table top while using the built-in phone microphone and a free SPL or dB app.

You can measure the amplitude of different frequencies as above using the built-in microphone and a free RTA app. Note, the typical music box mechanism is limited in frequency range from about 500Hz to about 4-5kHz and that what is primarily of interest are the frequencies below 500Hz.

You can measure the displacement using the built-in accelerometer and a free vibrometer app.

I hope this clears up a lot of misunderstandings regarding loudspeaker feet. Spikes came about in the early days of wall to wall carpeting to prevent the cabinets from dancing around by anchoring it to the underlying wood. Beyond that, the audiophile world has been misled as to their purpose. Rigid coupling feet will operate and perform the same function as the bridge does in coupling the strings to the soundboard of any string instrument.

In summary

- Rigid feet couple vibrations

- Vibration is a two-way street

- Spikes cannot drain energy to a heavier mass

- A small contact point actually amplifies vibrations

- Spikes cannot reduce internally generated cabinet vibrations

- Question one-size-fits-all and no lab report devices

- Isolation means the mechanical path is either broken, or the form of energy is converted to another form

- Properly designed isolation is predictable, repeatable, and neutral in performance

- Isolation will offer clarity that cannot be experienced with coupling, because with coupling comes additional, unwanted vibrations

- Isolation is easy to perceive

- Vibration transmissibility is easily measured