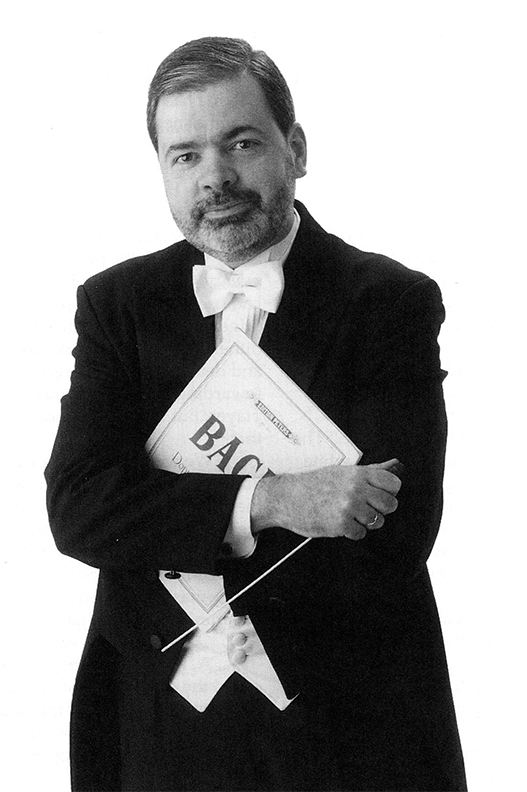

A special Positive Feedback guest editorial from John Marks, J.D. and James Tuomy, AES

John Marks has been a longtime audio friend of mine, and a respected member of audiophile recording and loudspeaker design community. He recently approached me to publish a technical paper that he and James Tuomy had written regarding proposed modifications to the Thiele-Small parameters for loudspeaker design. While this paper is more technical in nature, I think that there are some of our readers who will find it to be of interest.

Theory and practice being a continual dialogue, may the publication of this paper further the discourse within the audio arts for the greater good.

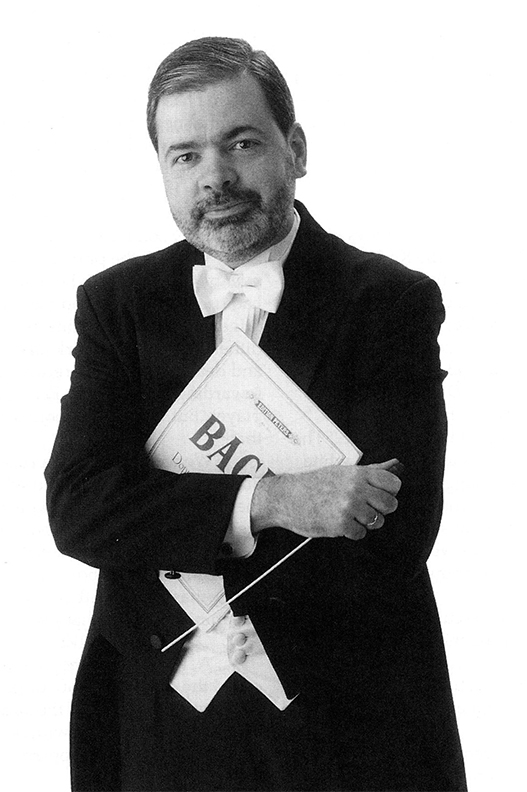

Dr. David W. Robinson, Editor-in-Chief

Co-Author’s Note: A loudspeaker-design client of mine asked me to research the optimal woofer-midrange driver to complement their "Crown Jewel" tweeter. In furtherance of that, I compiled a spreadsheet of more than 40 woofer-midrange drivers in the 5-inch size range. After weeks of slicing and dicing the data (and, simulating box sizes), it became obvious to me that the Thiele-Small Parameter Mms was a limiting factor, leading to dead ends. That is the background to what follows. "Load Factor" and "Agility Factor" are "Quick and Dirty" methods to quantify what an experienced loudspeaker designer might be able to intuit (or estimate) from scanning the data sheets on two different drivers. No more; but certainly nothing less.

A. Neville Thiele and Richard H. Small’s Parameters for loudspeaker analysis and performance simulation came to worldwide attention as a result of the republication of their individually-authored papers by the Journal of the Audio Engineering Society in 1971, 1972, and 1973.

Since then, the Thiele-Small Parameters have remained the primary analytical tools for loudspeaker-driver research and design. The Thiele-Small Parameters are also used for the evaluation and selection of "off-the-shelf" drivers, in terms of assessing their fitness for a specific purpose.

It was the latter utilization that led one of the co-authors first to postulate a new Parameter, intended to facilitate comparisons between similar drivers of different nominal diameters (for example, comparing the performance predictions of a 4.0-inch woofer, a 4.5-inch woofer, and a 5.0-inch woofer).

The Thiele-Small Parameter "Mms" (Total Moving Mass) represents the mass of the cone, the coil, and any other moving parts of a loudspeaker driver, plus the acoustic load created by the air in contact with the driver’s cone (or other moving element). By the way, according to C. A. Poldy, the "ms" in Mms and Cms stands for "mechanical system."[1]

Mms is unquestionably useful. However, if it is considered only in a vacuum, it risks being misleading. After all, one would expect the Mms of a 5.0-inch woofer cone, all other things being equal, to be greater than that of a similar 4.0-inch woofer cone. The real question, however, is whether the 5.0-inch woofer’s performance "scales up" proportionally to the increase in size—or more so, or less so.

In order to null out the effect of differences in driver size, the first co-author postulated a new Parameter. He calls this Parameter the "Load Factor" (proposed symbol "LF"). Load Factor is intended to be analogous to (or complementary to) the existing Thiele-Small Parameter "Bxl," which is also known as the "Force Factor." (Force Factor is measured in tesla-meters: T•m.)

The definition of Load Factor is: gs of Mms per cm2 of Sd

Or, "Grams of Total Moving Mass, divided by Square Centimeters of Driver Area."

In essence, Load Factor is an expression of density; whereas Mms is an expression of mass (or, more colloquially, weight).

To take, as an example, the German manufacturer Eton’s Arcosia 4-318, a 4-inch-class, 8-Ohm magnesium-cone woofer/midrange:

- the Eton Arcosia 4-318 has a Driver Area of 50 cm2 and a Total Moving Mass of 4.0 grams, resulting in a Load Factor of 0.08 grams of cone weight per cm2 of cone area.

It is informative to compare the Eton Arcosia 4-318 to another premium-quality driver in the same size class (however, a driver with obviously different design goals), the Purifi PTT4.0X04-NFC-01A, a woofer/midrange with a proprietary fiber-mix cone.

- The 4-Ohm version of the Purifi PTT4.0 has a Driver Area of 57 cm2 and a Total Moving Mass of 12.8 grams, resulting in a Load Factor of 0.224 grams of cone weight per cm2 of cone area.

That is a 280% difference.

At that point, the first co-author’s colleague suggested that, although the ability of the Load Factor analytical metric to null out differences in driver nominal diameters was helpful, it would be even more helpful if an analytical metric were also to take into account the Force Factor.

The first co-author then postulated the "Agility Factor" (proposed symbol "AF"). The definition of Agility Factor is:

Bxl/LF

Or, "Force Factor divided by Load Factor."

Applying this new analytical metric to the two woofer-mid driver examples above, the Eton 4-318 has a Force Factor of 4.3 and a Load Factor of 0.08, resulting in an Agility Factor of 53.75.

Whereas, the Purifi PTT4.0 has a Force Factor of 6.0 and a Load Factor of 0.224, resulting in an Agility Factor of 26.78.

The Eton 4-318’s Agility Factor is twice as large.

Of course, no single metric can tell the entire story. Among its other virtues, the Purifi 4-inch woofer has an extraordinary Xmax of ±8.5 mm, and a truly remarkable Fs of 38 Hz.

Table 1 shows data and calculations for ten different woofers in the 4-inch to 6-inch size range that were of research interest to the first co-author when he devised the new parameters Load Factor and Agility Factor. The authors hope that these analytical tools will make it easier for engineers and designers to winnow their "candidate lists" when selecting loudspeaker drivers for a particular purpose.

Table 1

Driver Comparisons, Ranked According to Agility Factor

Load Factor: LF = Moving Mass divided by Driver Area

Agility Factor: AF = Force Factor divided by Load Factor

|

Driver Name |

Nom. Dia. (inches) |

Sd (cm2) |

Mms (g) |

Load Factor |

Force Factor |

Agility Factor |

|

Accuton C158-8-085 |

6.25 |

113 |

12.1 |

0.107 |

7.7 |

71.96 |

|

Audio Technology 4H521306 |

6.0 |

96 |

8.45 |

0.088 |

5.66 |

64.32 |

|

Bold North Audio 4001 |

4.0 |

52.8 |

6.49 |

0.123 |

7.23 |

58.78 |

|

Scan-Speak Illuminator 15WU/8741T |

5.5 |

92 |

12.3 |

0.134 |

7.5 |

55.97 |

|

Satori MW13TX-8 |

5.0 |

70 |

7.3 |

0.104 |

5.7 |

54.80 |

|

Eton Arcosia 4-318 |

4.0 |

50 |

4.0 |

0.08 |

4.3 |

53.75 |

|

Morel TSCW 636 |

6.0 |

119 |

19.0 |

0.159 |

7.9 |

49.68 |

|

Eton Symphony 5-312 |

5.0 |

80 |

9.4 |

0.117 |

5.7 |

48.71 |

|

SEAS Excel Nextel W12CY006 |

4.5 |

50 |

6.9 |

0.138 |

5.9 |

42.75 |

|

Purifi PTT4.0X04-NFC-01A |

4.0 |

57 |

12.8 |

0.224 |

6.0 |

26.78 |

Driver data valid as of July 18, 2022

The practical utility of the Agility Factor metric should be obvious.

The "Take-Away" from the above table is that the driver with the smallest Moving Mass (and also, the smallest Load Factor)—the Eton Arcosia 4-318—is not the driver with the greatest Agility Factor. The driver with the greatest Agility Factor is the Accuton C158-8-085, because of its greater Force Factor.

The authors thank John Atkinson, Editor-in-Chief Emeritus of Stereophile magazine and a recipient of the Audio Engineering Society’s Richard Heyser Award, for reviewing an earlier version of this Guest Editorial.

John Marks is a multidisciplinary generalist and a lifelong audio hobbyist. He was educated at Moses Brown School, Brown University, and Vanderbilt Law School. He has worked as a music educator, recording engineer, classical-music record producer and label executive, and as a music and audio-equipment journalist. He was a columnist for The Absolute Sound, and for Stereophile magazine. His consulting clients have included the University of the South (Sewanee, TN), Grace Design, Fountek Electronics Company, Ltd., and Steinway & Sons.

Esperanto Audio, Lincoln, RI, USA; [email protected].

James Tuomy was educated at the Worcester Polytechnic Institute. He specializes in Product Development in the Consumer Electronics field. In 1998, he received Bose Corporation’s President’s Award. His consulting clients have included SimpliSafe, VOXX International, McDonald’s Corporation, Sharper Image, Sensory Spectrum, and United Artists Theaters.

4th Order, Inc., Charlton, MA, USA, [email protected].

FOOTNOTE

[1] In J. Borwick, ed., Loudspeaker and Headphone Handbook, 3rd Edition, ISBN: 9781136120855 (Focal Press, Waltham, Massachusetts, 2012); Chapter 14, at Figure 14.101. Electronic edition: https://www.oreilly.com/library/view/loudspeaker-and-headphone/9780240515786/ (accessed July 16, 2022).