Yes, V-TEE-I. That is not a typo.

VTI is not from New Jersey; they don't make turntables (although they support them nicely); as far as I know, the initials stand for something other than Virgo Taurus Industries. Actually, I had never heard of them until recently, myself. I was mulling the prospect of replacing my existing equipment rack(s) with something better suited to the limited space available in my new but smallish listening room. In my review of the Spatial Audio Hologram M-4 Triode Master speakers I included some pictures of the room. There is a handy nook at the listening end where I had placed my two equipment racks: a modified Zoethecus 5-shelf wooden rack for the main components, and a smaller Sound Organization metal rack for a second turntable or laptop / iPad, or evaluation / comparison of alternate gear. Moving from the dry New Mexico desert to the very variable island humidity of Martha's Vineyard had highlighted one of the problems of wooden racks: wood is hygroscopic. The Zoe was an intentionally "lossy" design—the shelves float on thin corner supports—but even after adding bracing and torquing up the bolts, giving the heavy Nottingham Spacedeck's platter a start-up spin caused the rack to flex or rock more than just a bit. Plus, while the bulk of the wooden rack was not a problem when I had it freestanding between the speakers, tucking it into the nook blocked access from the back and one side. Changing cables or components became an exercise in frustration and skinned knuckles.

My long-time audio budget rules are quite simple: no electronic component more expensive than the speakers, and no accessories costing more than a "decent" set of interconnects (or perhaps, a power cord today). Way back when Monster Cable was the thing, I built a "rack" from concrete pavers, glass bricks and silicone for $20. When I went with early XLO and Audioquest cables, a Target rack from the U.K. was a reasonable investment. (Even now, the current go-to budget racks from Audio Advisor nicely track their cables price wise).

OK, I'm no longer on a grad school budget. Unfortunately, "decent" as applies to audio seems to have mostly migrated well north of a kilo-buck for just about anything (interconnects included). I considered the familiar brands I knew from ads and audio shows, of course, but failed to get excited by exotic structures that re-purposed nuclear submarine technology to levitate massive components and the like. So I asked the Google for help—but mostly got links to the same usual suspects, and the discouraging sense that "audio-visual media cabinets" had pretty much supplanted "affordable" audio racks in the market place, as Zoethecus, Standesign, Sound Organization, Billy Baggs, Target, and other specialist sources have pretty much disappeared. I may not have the knowledge or skill to modify high-end electronics or loudspeakers, but I do have a reasonable understanding of what I want from an audio rack. Stability, isolation, utility, and adaptability are basic requirements—but as I have never been totally satisfied with any stock rack, I do have a few tricks up my sleeve to modify, the current term seems to be "to hack"—a fundamentally sound design.

One of my favorite Google tricks is to search "Images" or "Shopping" rather than "All." And so it was that I stumbled upon www.standsandmounts.com. They handle a variety of such things for AV and audio systems, including a few Plateau and Sanus racks, and dozens of variations on the theme by…VTI. (If you Google VTI Manufacturing, you will find their dealer list includes many other outlets ranging from stereo shops to kitchen and home décor stores, and at least one eBay seller, but Racks and Mounts' prices and service—Free Shipping!—were most appealing.) VTI makes 9 or 10 different styles of racks, with many options for number of shelves, color of metal frames, and with glass or MDF shelves (in several finishes), etc. Frankly, none of them reek of high-end cachet, but all would seem serviceable, affordable, and at least some are…hackable.

One style in particular caught my eye. While 90% of the world's audio racks are the traditional four-posters, VTI's BL304 series has but three legs. Why would that be my preference? Basic geometry: three points define a plane, and with an uneven floor like my basement's, it's much easier to level-and with inherently no wobble to fret over. Hey, I didn't do large-format photography for decades without appreciating a good tripod. Besides, the three-leg version is cheaper than the four (!). The second feature of note is that the shelf frames (base, 7'' and 9" high) are modular: with each level isolated from the others by spikes seated in integral cups, they can easily be stacked in any order (and extra shelves are available). The description says the poles are "sand or metal bits fillable," and all spikes and floor protection discs are included.

Yes, there are audiophile-approved 3-leg racks out there, but at audiophile prices. So I figured, for $288 shipping included, the VTI was worth a shot. I haven't bought any interconnects that cheap in some time, so I ordered an extra 7" shelf to boot, so the total came to just over $400. I debated the various color combinations: shelves come in glass or black, oak, or cherry vinyled MDF; poles in silver or black; spikes, caps and foot plates in silver, black or gold. I chose Oakland Raiders silver and black, in hope that the VTI rack would indeed be Stabler.

Racks and Mounts easily met their 3-7 day shipping estimate, the rack materializing in two surprisingly compact cartons. As one might expect, manufactured in China, but with obvious care in packaging. One carton had the basic four shelf frames, the other the base frame, MDF shelves, spikes, and floor plates. No Styrofoam was used, the frames instead inter-stacked and suspended by die-cut corrugated cardboard sheets. Frames and shelves were wrapped in bubbly, and even each individual spike and foot-plate came in a small poly bag.

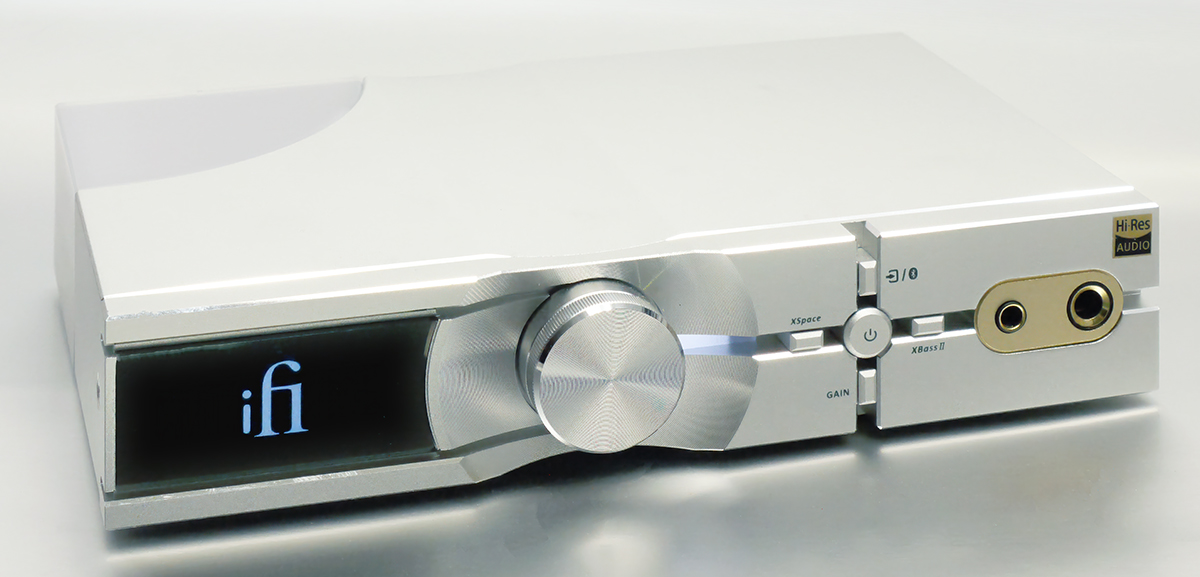

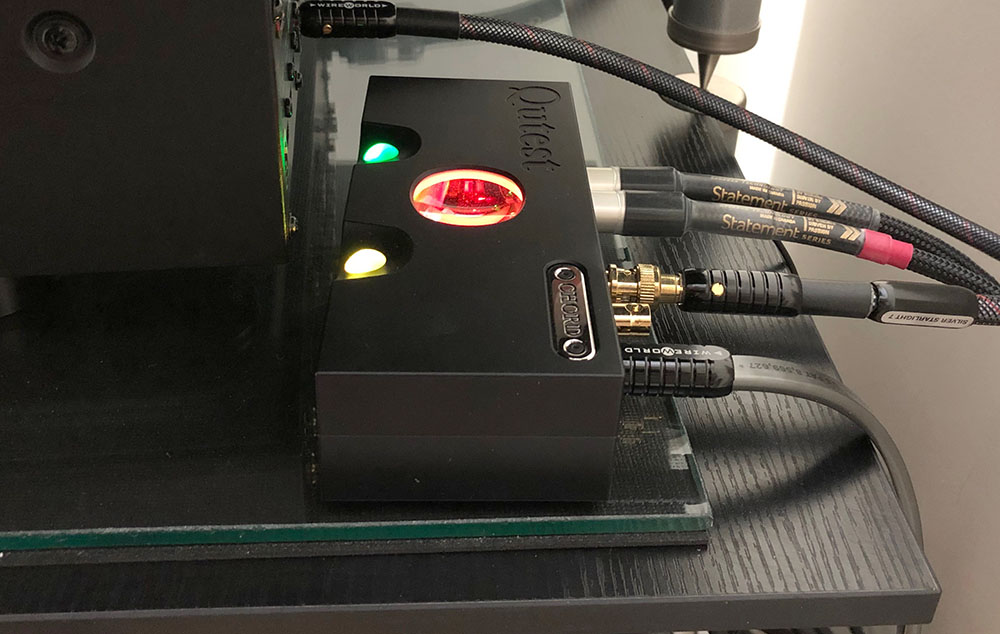

Construction appeared to be straight forward, and the overall fit & finish was quite good if not high-end luxe (the end caps, frames, and spikes are slightly different shades of "silver" for instance). The shelf frames are neatly welded to the pillars, the end caps apparently a snug press fit. The MDF shelves are approximately ½ inch thick, the vinyl wrap well done; in a nice touch, the cut-outs for the three pillars are blackened to match. Although the VTI is smaller overall, the actual shelves are significantly bigger (19" x 21 3/4") than the Zoethecus shelves, and even with standard size components, there is plenty of space for small devices like my Qutest DAC, iFi phono stage, and the step-up transformer I use with my Herron phono stage, etc.

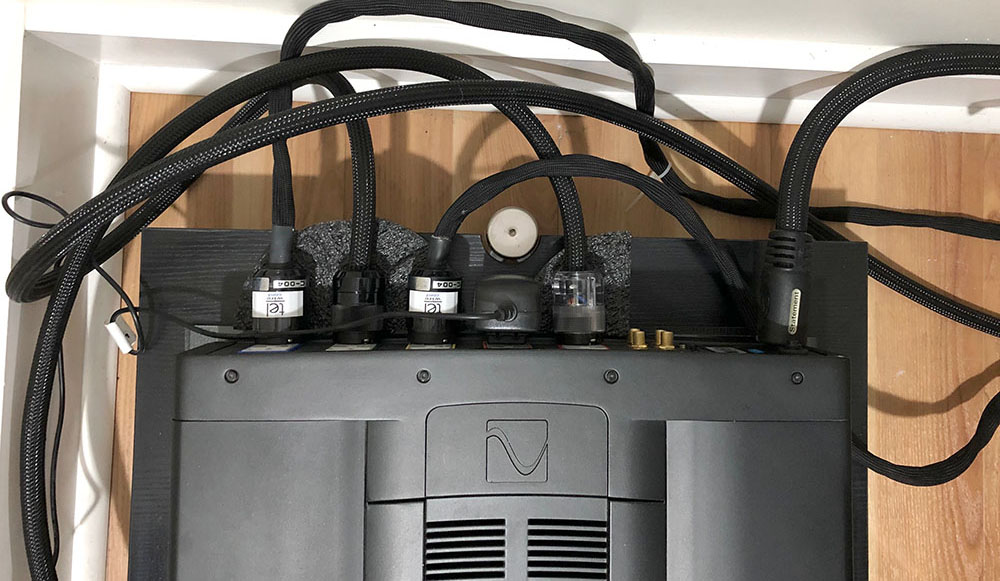

There is normally no assembly required other than screwing in the spikes and stacking the frames and shelves in whatever order desired. However, my basement slab floor is not level; while I could true things up by unscrewing the front two spikes, there is no jam-nut on the spike to eliminate wobble, and not enough thread to add one. Instead, I just used a couple of washers and tightened the spikes to level the frame. The frames are welded rather than bolted, and if the upper shelves go off level, a washer or two is the easy fix (the official instructions for resolving a possible spike/cup location mismatches involves a good whack or two with a mallet.) One of the real benefits of the modular design is the ability to plan out, install, and connect components sequentially as shelves are added. For example, I placed my power conditioner on the bottom shelf and plugged in all the power cords (with foam chocks under them) before adding the the second shelf and components, associated interconnects and footers, etc., and so on. I am done with trying to wrestle heavy gear onto a shelf horizontally only to realize I can't reach the back-side connections or adjustments. I can even take the turntable and shelf off to change carts or adjust VTA without actually touching it. Life is good.

But there are also several options to hack. If you pick up a shelf frame by a corner pillar and tap the frame, it rings like a bell. Actually, it rings like a triangle, basically because it is one. I could not resist clipping my guitar tuner to the frame and confirming it rang at an ideal concert pitch "A." (How's that for a "musical" component?). The web site description notes the pillars can be filled by sand or "metal bits" (by which I assume they mean BBs, buckshot, or depleted uranium, but can't say so for legal reasons). I recommend against sand for the pillars, as it will inevitably migrate into the spike threads, which need to be free should you want to re-level them in the future. You can easily adjust the mass-loading of the shelves to taste with everything from kitty litter to audiophile endorsed "metal bits." I've used BB shot in previous stands, but I prefer the coarse aquarium gravel readily available from a pet store, partly because when spilled it doesn't roll all over the place. Use the 10mm spike hole and a small funnel, and fill slowly. The trick is to not fill the pillars quite all the way, and then cram in enough cotton balls to block the opening so nothing spills out when inverted before you screw in the spikes.

It turns out the frame bars actually ring even more than the pillars. There is a small rectangular opening at the bottom of each end of a frame bar, probably needed when the bars are welded to the pillars. I filled the opening on one end of each bar with latex caulk. Grey blends in nicely with the "silver" finish, and any excess can be wiped away with a damp paper towel. After letting the caulk cure overnight, the bars can be filled from the openings at the other end. Here clean aquarium sand is ideal. To hold the frame in an inclined position (and to catch any spilled sand), I propped it up in a plastic tote bin. I attached the small funnel to a drinking straw-a clear one is best-and slowly spooned in the sand. When filled to the opening, simply seal it with a couple more squirts of caulk. The sand adds about 1.5 lb of mass per shelf, and result is an extremely "dead" shelf frame.

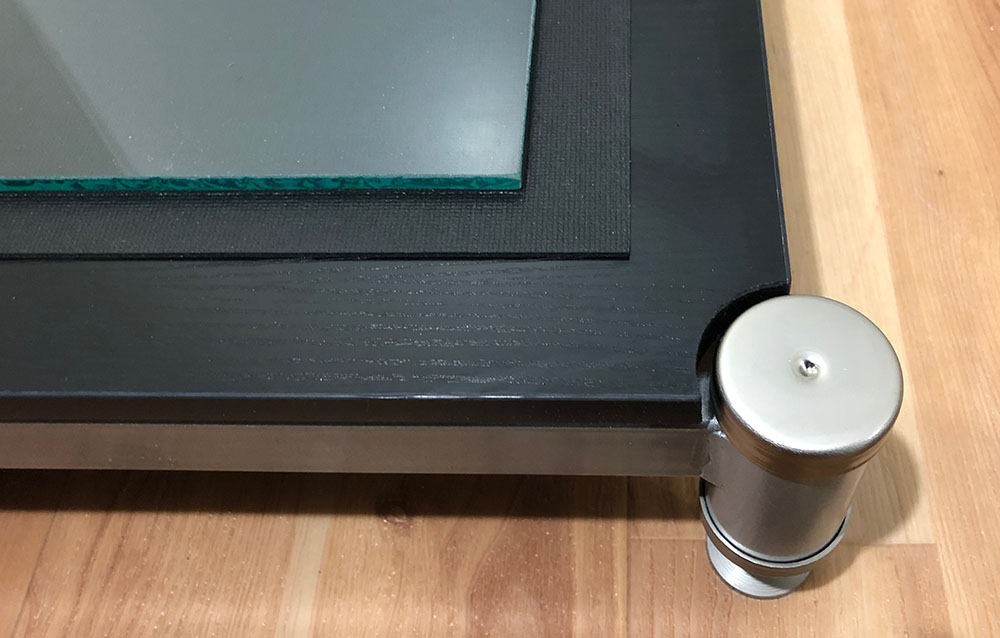

Next issue is the shelves. As noted above, I purchased the ½" MDF shelves, but .4"glass is an available option. Problem is, both MDF and glass "ring" (albeit at different frequencies). The simple solution I've used for years with various racks is to employ both glass and MDF, but separate them with thin foam "shelf liner" made for tool chests, available from big box home centers. This creates a low-rent constrained-layer damped shelf that is far less reactive than either material alone. I just transferred the ¼" plate glass I had used on the Zoethecus; in fact, because the shelves "float" I could have used the smaller but thicker Zoethecus shelves, or for that matter any other material-granite, butcher-block, Corian, etc. (Spoiler Alert: I'm already mulling trying one of the eco-friendly paper-based countertop materials for an over-sized top shelf turntable support). If you only insist on a ¾" MDF top shelf for a heavy turntable, this would drop in nicely. Bottom line, many more options than rack designs that clamp the shelves between the uprights.

Of course, it's in the interface between the shelf and the support structure where you can really channel your inner Science Fair avatar. There are different schools of thought on coupling / decoupling components and shelves. In general, the usual recommendations indicate a direct mechanical ground (cones, spikes, ball bearings) for gear that creates vibration (motors, transformers, etc.), and isolation (springs, Sorbothane, constrained layer damping, etc.) for components sensitive to external vibration (tube preamps, turntables, etc). The VTI frames come with two small, thin rubber pads per shelf support section-my Zoethecus had similar foam interfaces at the shelf corners. Of course neither the welded frame nor MDF panels are absolutely flat/level so one cannot be absolutely sure of the distribution of the load or control of shelf damping.

The easiest minimal contact area hard cone / spike alternative I tried was to use small round refrigerator magnets; they stay in place on the steel shelf supports but can be moved around to evaluate positioning, and one can add steel acorn nuts atop the magnets to further approximate the minimal contact of spikes or cones. With four post racks, the corners are the default support positions-which is why the "drum head" resonance of a shelf often becomes an issue. The three-pillar design places the shelf frames under the middle of the shelf, so there are many options for point-contact or vibration damping positions to deal with the natural resonance of the shelf.

However, the three-leg design trades off the "drum head" resonance for what one might call the "diving board" resonance of the unsupported rear corners. Rega fans will be familiar with the "light but rigid" support scheme, for which the supplied shelves are fine. Using heavy audiophile equipment on the thin-ish MDF shelves alone might only invite progressive back-corner sagging, but the glass and foam trick essentially eliminates that problem. For decades audiophiles have used small blobs of "Blu-Tak" (or similar temporary adhesive putties) between monitor speakers and steel stands; one could obviously use the same approach with a wood and metal rack, or perhaps just run a line or two of Mortite rope caulk weather stripping all along the shelf support rails? The stock shelves are constrained in place laterally by the deme-lune cutouts for the pillars, but a "sticky" interface might be a good choice for alternate drop-in shelving. As I wanted to be able to easily remove and change shelves independent of the frames, I also tried some 3/16" x 3/8" vinyl foam weather stripping…and I decided I preferred the continuous damping of the foam strips over the minimal contact alternatives. Dead, baby.

Finally, you can consider swapping out the supplied spikes. They are not very good at carpet piercing-they are primarily intended to interface with the cups and supplied floor protectors, and so the tips are blunted to about 1/16" diameter. They appear to be plated brass, and would be easy to file or grind down to a fine point for use on carpet. There are also numerous third-party spikes and audiophile footers out there, with not a few costing more apiece than the entire VTI rack. However, the de facto connection thread in the US is ¼"-20, and in Europe, 6mm and 8mm dominate. Many footer manufacturers do not have a stock version with the 10mm-1.5 thread the VTI expects, but most can provide adapters or custom machined solutions-as can any local machine shop. If you have or want to try alternative footers, a simple ¼-20 T-nut fits inside the 10mm thread of the pillars, and can be temporarily fixed in place with Blu-Tak, or more permanently with silicone caulk or epoxy. The trick is to thread the T-nut onto ¼-20 nylon bolts to protect the threads from the adhesive when installing. You can find inexpensive 10mm spikes on eBay (usually Chinese), and Music Direct has the lovely Track Audio 10mm spikes, but only at 8 for $149. Ultimately, as easy access to equipment and connections is a top priority in my cramped space, I ended up installing Herbie's Audio Lab 10mm Threaded Stud Gliders. These have a compliant silicone vibration absorbing interface, so are not quite as rigid as the spikes, as evidenced by the platter spin-up test. Otherwise, the mass-loaded rack remains quite stable, and I find no sonic issues with them. When needed, I can flip back the rug and slide the rack forward for access-providing I remember to pull only on the bottom frame pillars…

Altogether, I think the modified VTI rack meets all my criteria for an effective, adaptable equipment rack, and is a terrific bargain, especially if you don't mind a bit of DIY. Even though the assembly relies on gravity alone, it is stabler and less resonant than the more expensive Zoethecus, more compact, and much more configurable than many other racks. I still have my small Sound Organization rack beside it for my laptop, music files hard drive, and other accessories, but there is room in the nook for a second VTI instead…and I just might buy another one. Highly recommended-unless you live in an earthquake zone where gravity is not to be trusted!

Prices noted in the review

VTI Manufacturing

15046 Proctor Avenue

City of Industry, CA 91746

626.333.6638

Stands and Mounts

PO Box 145

Fuquay Varina, NC 27526

1.866.481.0634

1.919.552.8102