|

|

You are reading the older HTML site

Positive Feedback ISSUE 77

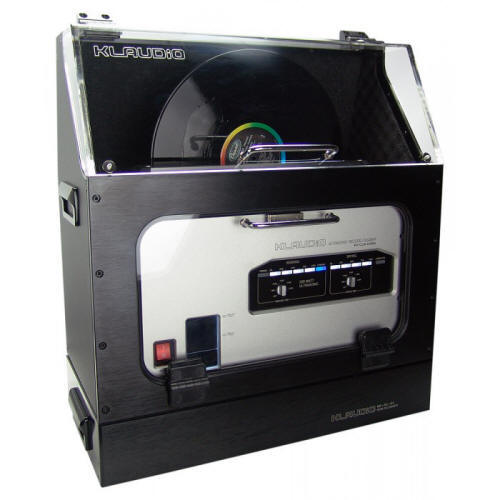

klaudio CD-CLN-LP 200 Vinyl Record Ultrasonic Cleaner V.4 and Silencer as reviewed by Myles B. Astor

KLaudio has introduced several significant functional and cosmetic improvements to their highly acclaimed ultrasonic record cleaning machine since my original report back in the September/October 2013 issue of Positive Feedback. Included among the many changes are: 1. The top loading record cleaning slot and the fill port for pouring the distilled water into the tank are now separated. According to the manufacturer, "the separate fill port allows for quicker filling and there's no need to use the smaller funnel anymore." Call me a dinosaur but I still prefer to use a funnel. In addition, a white light now illuminates the top loading record cleaning slot allowing for easier monitoring of the cleaning and drying process.

2. The separate on/off switches were eliminated in the latest version V.4 version of the ultrasonic record cleaning machine. While the separate settings allow for a wash-only cycle now, KLaudio doesn't recommend using it. 3. About a year ago, KLaudio switched over to nicer and sturdier handles for lifting and moving the machines. 4. KLaudio replaced the original drain valve with and an angled fitting to accommodate owners whose machines sit close to or against a wall. 5. The latest V.4 version of the record cleaning machine uses a white instead of the earlier blue light for illuminating the water tank. This is a vast improvement and allows for far easier viewing of both the distilled water level in the tank as well as its cleanliness! 6. All machines now come with a durable dust cover. 7. 10- and 7-inch adaptors for cleaning smaller diameter LPs are now available.

The most significant update, however, to the KLaudio record cleaning machine is hands down the Silencer soundproofing cabinet. This newly released enclosure literally deadens the sound of the ultrasonic cleaner like the silencer on the barrel of a gun. Deadening in this case is a good thing since noise is the eternal bane of record cleaning machines! Every vacuum-based record cleaning machine that I'm familiar with sounds like a shop vacuum; the ultrasonic based KLaudio unit's crackling is right out of a '30s Frankenstein movie (although the latest iteration of the machine seems slightly quieter than my first generation model). Acutely aware of the noise issue, Peter Cheon, designer of the KLaudio machine, developed the Silencer soundproofing enclosure that reduces the unit's operating noise level down to a very manageable 50 dBA. Indeed, equipped with the Silencer, the ultrasonic cleaning machine was now whisper quiet marred only by the sound of the fans turning during the record drying process. Still it was truly a true not to hear that raucous, grating zapping sound while the machine goes about its business. Is it now possible to clean records with the KLaudio and at the same time listen in the same room? Perhaps in a large listening room but in my somewhat smaller environment, I was always aware of the fans working during the drying process. Still, the fan sound was really only evident during soft musical passages. (Without the exhaust fans, the inside of the machine resembles a terrarium.)

Adding the Silencer to new (or existing) machines couldn't be easier. Each part of the Silencer comes well packaged and assembly, even for the most fumble fingered audiophile, takes less than five minutes. The accompanying instruction sheet and illustrations are clear, concise and shockingly, written in English. The bottom or base portion of the Silencer contains both the fans for exhausting the water condensation generated inside the unit during the cleaning/sonicating process as well as serving to dampen machine's sound. In addition, the fans can also run off a secondary, backup connection using an external 12 V, 0.5 A, AC power supply. Of course at the end of the cleaning cycle, the fans continue to run rather than shutting off when connected to the accessory port.

The solidly made upper half of the Silencer enclosure is constructed from brushed aluminum, steel and acrylic; its interior is lined with sound absorbing foam. Two acrylic doors on the front of the unit, each tightly sealed with a rubber gasket, allow for unfettered access to both the record loading slot and the machine's controls. Now make sure before assembling the KLaudio record cleaning machine and accompanying Silencer to choose a location that allows the top and side doors to easily swing open and closed. Task accomplished, the next step is to position the record cleaning machine on the black base. Then connect the bases' umbilical cord to the auxiliary power port located on the back left of machine. Finally, very, very, very carefully (make sure to carefully slide the top on or one of the knobs on the front of the machine can be broken off), slide the top piece of the Silencer over the machine and align with its base making sure that the AC cord passes through the slot on the back right. Mission accomplished!

All that's left now is to open the Silencer's front door and turn the machine on and select (if needed) the desired cleaning and drying times (assuming the unit is already filled with distilled water). Then swing open the top of the unit, drop the LP into the record cleaning slot and come back when the record cleaning cycle is finished and the machine beeps (the beep is a little harder to hear with the Silencer). For most LPs, a five minute cleaning and 1 minute drying cycle proves optimal. What, if any, are the downsides to the Silencer? First, the unit now has a much larger footprint and takes up more acreage than the stock unit. Second, sometimes there's slightly more "buffeting" of the LP during the drying process but certainly nothing to worry about or interfere with the cleaning process. Finally, I realized when rereading my original KLaudio review that the subject of how often ultrasonically cleaned LPs need refreshing was overlooked. As things turns out, it appears that records need recleaning far more frequently than originally thought to maintain their sonic pristiness. (File this under the funny, didn't notice the gradual decline in the quality of the sound until the records were recleaned) Now it's not clear whether it's my use of a record brush to whisk cat hairs off the LPs, some outgassing from the plastic inner sleeves, the dirty environment of New York City, the realization of just how good an LP can sound, etc. but there's absolutely no doubt that ultrasonically cleaned records need a regular recleaning every five or ten plays (at most). The biggest benefit? The return of that holographic, three-dimensional imaging along with that overall drop in the record's noise floor. Kudos to the design team at KLaudio for continuing to improve upon an excellent product and last year's PF Product of the Year. While the new Silencer equipped model does require a little more space, the new found silence is golden! Highly recommended! Myles B. Astor

KLaudio Vinyl Record Ultrasonic Cleaner

KLaudio Silencer, Acoustic Dampening Case for RCM. Weight: 31 pounds.

7-inch/45 rpm adaptor: $99. 10-inch/33 and 78 rpm adaptor: $99. |