|

You are reading the older HTML site

Positive Feedback

ISSUE

5 The Bluenote Bellavista/Borghese/Boboli Package: A Belissimo Vinyl Front-end!

Of turntables, materials and beauty

The "Made in Italy" Villa® turntable-tonearm-cartridge "Bellavista" package, made by Bluenote®, is a subtle mother to describe beyond the obvious: it's drop-dead gorgeous to look at, its price is $1995, and its performance level is excellent in its "rigid chassis" class. The reasons are two: Bluenote® has invested much of its manufacturing cost into its chosen materials, and the Bellavista is beautiful in the way of a Cremonese violin—where form follows function to produce gorgeous tones from a visually beautiful instrument. For example, did you know that an acrylic (the polymer formerly known as Plexiglas) plinth costs seven times as much to manufacture as the same Medium Density Fiberboard (MDF) plinth? Well it does. And a turntable platter made of Polyvinyl (similar in many regards to the LP record material itself) costs half-again more than an acrylic one, and even more if it has twelve jewelry quality (10 micron) gold-plated brass weights fixed to its underside, for rotational stability. You needn't go much farther than look at a Needle Doctor ad to see how many turntable manufacturers are using MDF plinths, and acrylic (Plexiglas) platters in their products. What sets the Bluenote Bellavista apart is its superior engineering, superior materials, hence superior sonics, and its beauty—for which we are indebted to its designer, Maurizio Aterini. A guy I knew, the proud owner of a Moto-Guzzi motorcycle, once commented; "Ever notice how American bikes have all their heat fins at right angles to the cylinders, while Italian bikes are all curves, like a woman?" I think Maurizio thinks designing a turntable to be attractive is part of the Italian tradition. The guy is from Florence, after all; the golden city of Dante, Leonardo, Michelangelo, Raphael, and Donatello. Some tests of specifications The manufacturer's performance specifications for the Bellavista are as follows: wow and flutter, 0.03%; rumble, -78 dB; speed, 33.3 or 45 rpm + or - 0.1%; all very good. The first thing I did after setting up, following the direction of the distributor, Adam Dragon at Hy End, was to let the piece run continuously for eight hour stretches, three days in a row, to "polish in." Then I placed the 12" Villa® stroboscope on the table and checked it against 60 Hz light. It was highly stable. I wanted to check it with an LP record and tonearm dragging. I was able to do it with a smaller old strobe I found amongst an old collection of odds 'n ends, marked "Dual, Made In Germany, 60c/s." In use, the strobe bars were very stable. There was a very slow drift, and virtually no bumps, or surges. The platter got up to speed quickly and stayed there. To get the bars to reverse, I had to press my thumb upward on the underside of the turntable with some force. I wasn't sure how it performed with the additional friction of playing an LP record. But when I put a black disc on, next the Dual 4 5/8" strobe on top of that, and next the tonearm and cartridge tracking at 2 grams, there was no change discernable to the naked eye. The current came through my astonishing Monster Automatic Voltage Stabilizer (AVS2000), which supplied a consistent 120 volts (more on that soon). I'm relatively certain, without fancy measuring devices, the table's rotational speed is pretty damn close to being within the manufacturer's stated specification of 0.01%. LP recordings of which I have a duplicate CD sound very similar as to pitch, and elapsed playing time is as specified on the labels and liner notes. This is the only "hard data" I have. A thirty minute movement (30:00) of a Mahler Symphony would take exactly 29:42 if the machine were 1% fast. It doesn't. The B side of my Mahler's Fourth Symphony (Pittsburgh Symphony Orchestra, André Previn conductor, Elly Ameling soloist, EMI SZ-37576) is reported to take 30:30 to play. It timed out at 30:34 (that's four seconds slow out of 1834 seconds) on the Bellavista, when I measured it with my best timepiece. That could be due to human error, or the imprecision of lead-in grooves. Molehill or mountain? A scandal in Bohemia? "Don't tell Cesaré!" I don't know if you know, but we audiophiles may be in the middle of a scandal, or a tempest in a teapot, or a molehill made into a mountain, regarding speed of turntables. If you've been reading Stereophile lately—Michael Fremer's survey of six moderately priced turntables these last two issues, to be precise—you would have found at least one article (Feb. ‘03) where Fremer discusses how some turntables (SOTA Comet II, and Rega P3) that he measured with some rigor each showed a speed variation of 1% plus. That means a slight increase in speed from 33.3 rpm to 33.63 rpm, and that correlates with a subtle change in timbre—if not a large enough gain to produce a gross change in pitch. Fremer reported his test record's 1000 Hz tone actually measured 1011 Hz when played on these turntables. "Things sound snappy and lively, but a bit crisp: heavy on transients, light on harmonics. Images are forward on the stage, with a bit of etch added to cymbals and female vocals." On some tracks the music can become "slightly aggressive," he observed. Fremer quotes others who speculate the designers may have deliberately voiced their turntables with this subtle speed increase. His exact words were, "I'm not happy about the 1% speed error; if it's deliberate, it's a cynical move—like lifting the top end of a loudspeaker to make it jump out from the crowd." He stops short of saying anything actionable beyond he's not sure "if this represents mere sample-to-sample variation or if it's a plot to give these 'tables a snappy delivery, as some who shall remain nameless have charged." (My emphasis.) This seems to me to be like a "non-denial, denial" in political geek-speak. He takes the higher moral ground by repeating the allegation, and the lower moral ground by withholding the name of the "alligator." Then again, I am doing the same. But, I don't take the higher moral ground, and I don't know the identity of the "alleger." I am willing to give the SOTA and Rega designers a little more slack, a more charitable interpretation. Suppose, for example, the designers measured all the friction points in the system, including stylus drag on the record, and counting on lazy louts like us to fail to perform routine maintenance, like lubrication. And suppose they assumed that all those factors might contribute to an error of about -1%. If they wanted to pre-empt such error, well, they just might build in a little preventive maintenance, and run 1% fast. That might be playing fast and lose with the specifications, but in today's world it might be justified on the "need to know" basis. "What the public doesn't know won't hurt them." At least they might be seen as doing a bad thing for a good reason. Or, suppose, for another example, using all the research methods at hand they chose certain resonant-manageable materials for the plinth, platter, and pulley of their turntable (to make a price point) but found the table sounded a bit dull and soggy as a consequence. Wouldn't it be within their job description to try to overcome soggy sound by other means within their pharmacopoeia? I think tweaking the speed might be no more "evil" than Niccolo Paganini's tuning his violin up a tone for greater brilliance, which he reportedly did. Again, they might be doing a "questionable" act for a reason that serves the music. They'd be within the spirit, if not the letter of the law. I'd be willing to forgive either of the above cases. Though, in retrospect, it would have eliminated vagary of motive if SOTA and Rega would have explained such in the owner's manual. For a final example; suppose they had ordered pulleys from a (possibly off-shore) supplier and found one batch that (inexplicably) sounded better, because the machinists had made the pulleys (unbeknownst to anyone) fast by virtue of a 1% error, but no one along the line had bothered to check the speed accuracy, as Fremer himself admits he had sometimes failed to do in the past while preparing reviews. Such failure might be seen as a failure due to slippage within the system (the mistaken assumption that everyone else is doing his job accurately), rather than of some sort of cynical manipulation, or "plot" (to use Fremer's word), to lure the would-be purchaser. I'd prefer to think of it as a normal futzup, because if not a futzup, then we might as well throw all manufacturers' published specs out the window. Possibly I'm naive, but I don't think manufacturers would purposively fudge their test data, when, as Fremer's rigor demonstrates, they could be so easily discovered. Poles Apart: 12 or 24 How does this relate to the Bellavista? To cast a little light on the dark corners here, I am obliged to mention one of the 'tables in Fremer's survey uses a 24-pole AC Synchronous motor (the SOTA Comet II), while two Pro-Ject ‘tables use a"wall-wart-powered AC motor suspended by an elastomer band" (RM-4 and Perspective models), Notingham Analogue Horizon 'table has a motor that must be manually assisted in order to get the table into motion, and two unspecified motors are found in the Rega P3 and Pro-Ject RM-9. The Bellavista uses a 24-pole AC Synchronous motor. The beauty of this motor, (what used to be called the hysteresis motor), is the RPM setting is dependent on the cycles of the AC current fed to it. That is to say, as long as the current alternates at 60 Hz the motor speed is constant. Even if there is a significant drop in line voltage, a good AC Synchronous motor turns at its designed constant speed (say, 600 rpm). Twenty-four poles spread the current peaks out to double the frequency per unit time delivered by the often used 12-pole AC Synchronous motor. Compared to the 12-pole motor, the 24-four pole motor develops less torque, hence less noise as well. So the 24-pole AC synchronous motor stays on speed even when voltage drops, smooths out the delivery of the torque, and is noticeably less noisy than its 12-pole counterpart. According to Maurizio Aterini, the design engineer of the Bluenote line, his motor is manufactured by:

I don't know too many engineers who are so confident of their decisions they would let such information out of the office. What I take it Maurizio is saying is: "Here are my motor's specs. See for yourself." The relative quiet running of this particular motor allows it to be mounted on the same plinth as the turntable platter itself, because not only is the polished acrylic plinth more beautiful than painted MDF, it has better vibrational characteristics as well. Again, according to Maurizio, it is much more neutral sounding because acrylic is harder and can dissipate vibrations, while MDF has a higher Q (it stores and later releases energy) and adds a characteristic sound smearing in the same application.

MDF or Black Plexiglass Again, using the wonders of modern Email, Maurizio has sent me some specs on various materials. See for yourselves:

This comparison reveals to me that Black Acrylic has various physical attributes (harder, stiffer, doesn't bend or sag) that make it a better material if what you want is low Q (energy storage), hence more neutral sound, at the source of your LP front end. Without sounding like a hometown fan, I've never been to Florence, I'd say whenever the choice has been between a price point and performance, Maurizio has been uncompromising. This seems to be the case throughout the design, and up the line into the more expensive of his turntables. With each choice, Maurizio has gone for the better sounding: 24 pole motor; plexiglass plinth; (denser, stronger, more neutral polyvinyl) platter; (automatically self-lubricating) bearings that are longer than ususal (to eliminate wobble that gives wow and flutter); (quieter than aluminum, better coefficient of friction Delryn) pulley; (better coefficient of friction, ceramic injected for better traction) belt; etc. etc. Then he offers to us an outsized stroboscope (at least twice as easy to notice variations in speed), as if to say, "Check it out. See how good we can do." How good does the Bellavista turntable get? Surprisingly good. Remarkably good. He has said to me in an email: "Our 24 pole AC Synchronous motor produces 600 rpm with more accuracy than the Rega or Clearaudio that have 12 pole 300 rpm motors, basically because of the closer position of the poles." Ya gotta love this guy's moxie. "I do not think our stuff is 'special.' I simply think that we designed well what other manufacturers did not. All our designs ... have been trying to follow the best sonic performance through balanced research and manufacturing." Borghese Tonearm

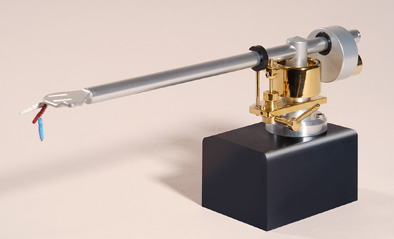

This is more or less true of his uni-pivot Borghese tone arm as well: wherever possible he designed in the best performing sonic materials (controlled vibrations) that were within his options. I'm talkin' 'bout good vibrations. Maurizio selects the material he will use for a specific part (anti-corrosive aluminum, brass, bronze, stainless steel, titanium), and then machines it with very strict lathe tolerances. The Borghese tonearm tube wall, for example, is made of 0.8 mm thick 6060 aluminum alloy drawn stock, "the hardest tube available using aluminum alloy," he says. After it has been extruded and polished, it is anodized to make it harder and more resistant to scratches. It looks like it is merely brushed aluminum, but it has the strength/weight ratio that Maurizio wants, and the vibrational characteristics befitting a tonearm. With regard to arm geometry, Maurizio follows the Rega standard, where possible. The arm tube has an overall length of 270 mm, and from the center of the pivot 232 mm to the front of the cartridge shell. Each of his tonearms has an undamped inverted internal pivot, with a 0.2 mm rounded and polished stainless steel tip. The pivot towers are made of decoupled bronze jacketed onto brass, and anti-corrosive aluminum, with selected parts being gold plated. The internal wiring is done in OFC OCC hyper litz copper and is completely shielded with a fine stainless sock inside the arm tube. The external cables, also shielded, have been made to specification by Tasker® and feature very well designed, sprung RCA plugs. Each part represents a great deal of engineering thought. Setting up this tonearm is a bit of a fussy exercise, but Maurizio assures me that an instructional DVD for setup will be forthcoming beginning in March. (Oversized stroboscope, DVD instruction manual for set up; a class act.) Boboli Cartridge The Boboli cartridge, named for a sweet after dinner pastry, is a high-output moving-coil that looks like some others of the "nude stylus" variety. It has an output of 3mV, and weighs 7 grams, which means it will play in any pre-amp or receiver that already has a phono section without having to use a separate phono stage, and it will track in most any arm. In this era, we all are sophisticated enough to know that it would be a bit much to expect a small company making relatively large tonearms and turntables to also make its own miniature cartridges (Grado, for example, doesn't make turntables.). But a design-engineer with the sophistication of Maurizio Aterini could specify to a large cartridge manufacturer just those vibrational qualities that would make a given cartridge a perfect match for his tone arm. I assume that's what has happened here, because Maurizio's combination seems to have a synergy, a complementary relationship that makes the pair's performance greater than the sum of its parts. The Boboli in the Borghese is quite a surprise. The Bellavista special package may not capture the last percentage points of data that are in the LP's grooves, but it gets to the heart the of the vinyl experience. It offers the listener suave handling of music that early mid-fi CD players (with their etched sound) so obviously lacked. Maurizio's top of the line Bellagio table has a better isolated motor, a better designed spring-loaded "sub-chassis" to better control airborne (music) and mechanical (footfalls) feedback, a twice-as-massive platter, sixteen as opposed to twelve rotational stabilizers, a machined titanium tone arm tube, and a high-performance low-output Moving Coil cartridge that together cost four times as much as the Bellavista special package. Maurizio's top of the line rig (Bellagio table, Borromeo tonearm, and Baldinotti cartridge) definitely delivers lower noise, greater stability, better vibration management, and, he claims, noticeably better sound; more "powerful, detailed, focused, and open." But, it uses the same motor, the same bearing, the same pulley, the same drive belt, the same acrylic in the plinth, the same turntable platter (only two of them), etc. Considering the price point, the Bellavista special package is something like a very talented little brother. How Does Any Turntable Sound? Since in order to listen to a turntable's performance we must depend on a tonearm and cartridge, it might serve well this review to try to tease these differing "sounds" apart. Let's start with tonearms. How does a tonearm sound? Well, the overall performance of a tonearm is limited by the quality of its bearings for tracking, the vibrational characteristics of its materials for managing vibration, its mass (hi-lo-medium) and how well it matches various cartridges' compliance, and its geometry to minimize tracking error. They are certainly each important. But, in my experience, none of these is as important as its shape: a tonearm (be it ess-shaped or angled) topologically most resembles a piccolo. This means its natural resonance is high, and audible in the treble range. Undamped tone arms are often perceived as "overly bright," sometimes too "metallic" in tone, when working with well known cartridges. Tonearms have been around a while now and even the worst of them seem to have worked out a lot of the problems. The "too bright" tonearm can be remedied somewhat with a glob of Mortite© between the cartridge and the tonearm's mounting shell. If the tube rings like a bell when you ping it with your thumbnail, one remedy I've heard of is to run a bead of clear silicone glue the length of the underside of the tube. But, in large measure, tonearms' problems with unwanted resonances have been significantly reduced over the years. Cartridge/tonearm combinations can produce an almost infinite number of colorations, and to varying degrees. The Borghese/Boboli combination does not alter instrumental timbre leading to confusion (of, say, an oboe with a violin, or a trumpet with a clarinet, a pretty gross error), nor even add a shade of coloration to a well known performer's instrument (Yo Yo Ma's cello, say). It is also precise with regard to channel separation and sound staging. It can play the loudest passages without mistracking. It reproduces the moment of attack with clarity and freedom from ringing. It captures the drumstick tap on the drumhead, loud or soft, with almost uncanny ability. It seems to stop generating signal when the groove stops sending it. A metaphor from automobile design seems appropriate here: it has good "braking horsepower." It may lack the refinement of its big brother (the Baldinotti cartridge in the Borromeo tonearm), but it does a very nice job. Isolating the sound of a turntable is hardest, because it interacts with the tonearm and cartridge. You would have to have heard the tone arm and cartridge on other tables, or know their reputation, or both, to infer what the turntable itself is doing. I have spent long winter afternoons with audio pals listening for differences in a half-dozen turntable platter pads, taking notes on each, comparing notes only at the end. I have spent hours talking to, or swapping email with, turntable designers, audio shop owners, and other lunatics trying to gather information on the characteristic sounds of turntables. I have found only a few guideposts to point the way. First, is the turntable puck or rim-drive, belt-drive, or direct drive? Rim-drive usually has a hard rubber drive wheel that links the motor to the platter and it feels like riding over a gravel-based road. Belt-drive usually has a soft plastic belt that links the motor to the platter and it feels like riding on smooth MacAdam asphalt when compared to all but the best rim-drive. Direct-drive (the rotor of the motor is on the same shaft as the turntable) units are subject to all sorts of expensive problems to design around, and even their best executed examples (Technics) have problems: regulating the current, and isolating the entire assembly against mechanical insult. At best, they sound as good as the best belt-drives. But the problems can be very expensive to work out. Belt drive turntables are more demanding about materials. Rigid or spring-loaded, the chassis of the turntable becomes acoustically excited when music is played. The plinth that supports the bearing well, and therefore the turntable itself, can have a sonic thumbprint. Rule of thumb: less costly materials usually have resonances that find their way back to the table, hence the stylus. If the plinth supports only the turntable and the tonearm, that's not too bad. If it also supports an un-isolated motor, that's usually a problem (but not for Maurizio). One model reviewed by Mike Fremer in Stereophile's recent (Jan. ‘03) article, the Pro-Ject RM-4, had a plinth of Medium Density Fiberboard, and a turntable platter of High Density Fiberboard. Not surprisingly Fremer commented, "...the RM-4 was limited in its ability to carve out instruments in three-dimensional space, its dynamic capabilities were somewhat stunted, and it did only a so-so job of resolving low-level details. Transients were somewhat softened, and bass, while impressively extended, was robbed of articulation and rhythmic drive." With what is known of the Q characteristics of MDF and even HDF, and shown in Maurizio's tables, those are exactly the sonic characteristics we'd expect. They are why Maurizio keeps away from those materials, even though HDF is easily machined. The sonic characteristics of the RM-4 that Fremer reports, are the result of vibrational energy absorbed by the chassis, for a short time, and then released and picked up by the cartridge along with the groove information. The two time-staggered signals blended into one is called smearing, and it results in a lack of clarity. It is what good turntable engineers design out. Getting rid of all the parts that potentially store energy becomes something like a jigsaw puzzle. With what does one replace MDF? Without overdamping the bass? And what about spring-loaded plinths? A good designer can work out the resonant frequency of the springs, the frequency of the materials and mix and match until he can "tune" the bass frequencies. He can select the platter material and pad to "tune" the mid-range. And he can tweak the tonearm to "tune" the highs. A good designer can develop a systems approach to the vinyl front end. And that's what Maurizio has done, though he doesn't say so in as many words. And that is why the Bellavista package enjoys synergy. As a counter-example, the three ‘tables reviewed by Fremer in his Jan ‘03 article are three different types, using three different sets of materials. The first is the Pro-Ject RM-4, already discussed. The second is the Pro-Ject Perspective, and the third is the Pro-Ject RM-9. The RM-4 and RM-9 use an MDF plinth, the Perspective uses a clear Plexiglass plinth. The motors are different. Yet, "All three of these ‘tables ... include Pro-Ject's premium 9" arm..." For the purposes of his article, using the same arm and cartridge allows him to compare the sound of the turntables alone. Fremer has isolated one variable: the turntable. That's good methodology. But that doesn't make for matching the tonearms to the characteristics of the turntables. Looking at each of Maurizio's tonearms, it seems he gives more thought to materials and finish as he goes for improved performance up his price ladder, though the design is the basically the same (9" uni-pivot). Villa turntables are similar but each step up is incrementally more refined, better isolated, more massive, with lower noise. And each ‘table seems to be designed with its appropriately matching tonearm in mind. How does it sound? For pity's sake. How does it sound? To really get my head into it, I dragged my old reliable (heavy) VPI HW-19 turntable down out of its shelf, and I replaced it with the Bellavista. After listening to it in my big system with which I've spent thousands of hours, the verdict was in. The improvement in sound was such a revelation I sent away to VPI for a new set of Plexiglass parts (plinth, tonearm board, and motor cover), and a new Plexiglass turntable platter, with a new inverted thrust bearing. I'm also replacing the machined aluminum pulley with a Delryn pulley. I know when I've been put to shame. My old turntable was revealed as more than a wee bit imprecise, what with an MDF ‘table plinth and tonearm board. The bass seemed more than just a tad bloated. I had thought that the bloom on the base of so many LP players was a function of low cartridge braking horsepower. I was wrong. And the midrange that I had found a bit forward seemed "in your face" when compared to the relaxed presentation of the Bellavista package. How would I characterize the package? Compared to my old table, it is as Maurizio says, more "powerful, detailed, focused and open." It is powerful in putting down a rich bottom strata of sound, the bass viols, organ pedal tones, and the slam with which to listen to my old Jimi Hendrix sides. It has great dynamic range power. It has bowl-you-over bass drum power. But the bass is not a false bloom that results from overhanging transients. The special package presents a richer mixture of sounds with a good amount of "warmth," as opposed to a "cool, analytical" sound. I think "rich," like a ruby Port, is the operational word here. It has details aplenty, not the false details of a rising mid-treble, or a ringing tonearm, but true details finally, free from smearing brought on by high Q turntable parts. Each line in a three part invention on the harpsichord is clear and distinct from the others. Each instrument in a monster orchestral climax is clear. There are details, and there are details. Mies van der Roh once famously said, "The devil is in the details." There are real details and apparent details. Hearing the lips, teeth, tongue of a singer close as possible to the microphone is what I'd call a false detail that detracts from the performance. Singling out one voice in a choir of a hundred, singling out that voice because it is articulating what the musical moment is all about, is a true detail. Which leads us to focus. The Bellavista has the kind of focus that allows the listener to concentrate on whether a slide guitarist is using a metal slide or the neck of an old bottle that just happens to fit his pinky comfortably. It allows the listener to hear the St. Petersburg Symphony Orchestra of Russia and wonder if the bass viols are using strings wrapped in bronze or stainless steel. It is rumored their strings have greater projection, greater volume, and a higher treble output. It allows the listener to think of which microphones were used in various Linda Ronstadt records, to capture the throb in her voice when she sings how some dude broke her heart. A lot of what I'm getting at has to do with the first instant of a new note. This package has the focus that allows us to hear that cleanly. I've heard it said that rigid chassis have a narrower and tighter sound field. That many spring-loaded chassis turntables display a wider, deeper sound stage. Well maybe the exception proves the rule in this case, but I found the sound stage of the Bellavista package just about as wide and deep as my old spring-loaded VPI. Because there was a nearly total elimination of smearing, and the new clarity made spatial cues easier to "catch on" to, I think the quality of the openness was improved on. The Bellavista doesn't present more openness, it presents clearer openness — which might mean the same thing in the end. It presents "opener openness." I'm starting to sound like George Carlin, here. I think I'll quit while I'm ahead. A caveat or two Some caveats. As it stands, the Bellavista is sensitive to footfalls in some rooms. This may be a problem. When I moved it from my office's countertop, a structure that is secured to the wall and where it sounded nearly optimal, and placed it atop a free-standing old equipment rack downstairs, I found it became much more sensitive to acoustic feedback and foot falls. In a frantic hurry to remedy this, I contacted a few guys and was advised to get two large (24' x 18") maple cutting boards, and to put a one inch slab of open cell foam in between them. I did. What can I call it? A primitive resonance-control sub-chassis? This device eliminated nearly all the resonances that were making their way back up to the stylus during crescendi. Things cleaned up even more. And the effect of footfalls on my very springy floor was reduced. All this for about sixty-five dollars. I also found that when I switched from my improved Black Cube to my Grado phono section, a tendency toward brightness was reduced. With these two adjustments I got the results I describe above. The Bellavista special package (‘table, arm, & cartridge) is a sonic winner. And it is killer beautiful to watch in operation. Those little gold doobies come whirling by, like cars in an amusement park ride, reflected off the highly polished plinth. They are way cool! The gold-plated parts dress the ensemble up enough to be eye-catching. The 10 micron gold plating that ornaments the piece is not only beautiful, it retards unwanted high frequencies. Naah. It doesn't. But you can tell your buddies, and the ladies, it does. Who can say "No!"? Once they hear this rig, you can say anything, and they'll believe it. It's hard to believe it has been much improved upon. But I know Maurizio has. "Bella vista" means "beautiful view" or "panorama." Not only is the Bellavista itself beautiful, it opens up a beautiful panorama of the world's great music. Ciao, Bambini. Component Summary

Retail: Importer Manufacturer's Comments First of all, I would like to thank Auro D'oro for his very insightful review of our Bellavista package (Bellvista 'table, Borghese Tonearm, and Boboli cartridge). I think he basically understands the philosophy behind our products and our company. That is not so easy to understand as it would seem based on Auro D'oro's advice. In fact, our being quite in conflict with the "regular" hi-fi approach in designing 'tables and arms, we normally have to suffer misunderstandings more often than people might expect. So, I hesitate to comment in detail about what Auro D'oro has written, it is just too comprehensive. I would like to suggest owners place our Bellavista as far as possible from the center of wooden "floating" floors; at least to avoid walking close to the turntable while music is played. Auro D'oro suggested dampened maple cutting boards to help listeners in such situations. The best solution, in my opinion, to avoid (most of) the problems foot falls create is to place the turntable on a shelf directly fixed (screwed) to a wall. In addition, I feel it is important to underline a couple of mistaken impressions about our top-of-the-line Bellagio 'table compared with the Bellavista 'table that might mislead the reader. The Bellagio is not merely the Bellavista table with improved mass. The Bellagio platter is a double Sustarin® (Bayer® Germany patented acetalic polymer) has different technical characteristics to the PolyVinyl used on the Bellavista. Also the lower and upper platters are decoupledthrough five Teflon® rectified rings and are fixed with five large stainless steel 8mm thick allen screws. Sustarin® not only is better for sonic purposes (being a much better self dampening material that diffuses vibrations faster), but due to its molecular structure is harder to machine, so having a higher rejection rate makes it even more costly. The double plinth boards, where the platter spins, are laser cut with a particular curved shape that not only increases rigidity but also discharges vibrations. The lower transparent acrylic board is used only to fix the three conical feet to three 110mm tall, 8mm thick Titanium threaded bars in true perpendicularity to the acrylic board. The motor is better and is fixed on the transparent board, not because we thought it was nicer than to make a hole to put the motor on the the 'table's shelf support (a la Michell), but because, considering that 90% of final users do not know the vibrational characteristics of shelf boards (which, in the final analysis, transfer vibrations to the platters, too); we preferred to fix it where we had the opportunity to develop a proper anti-vibration design (a motor cylinder box to match with a 15mm thick, 450mm deep, 550mm wide transparent board). The arm board is better and absorbs more vibrations coming to the turntable platter than the Bellavista's arm board. The bearing spindle system is the same but polished on every surface to guarantee a closer tolerance and so less friction. Kind

regards, |