You are reading the older HTML site

Positive Feedback ISSUE

july/august 2008

Paper or Plastic? Vinyl's Final Resting

Place: The Next Installment

by Myles B. Astor

Despite a well earned reputation for never agreeing on any subject relating to audio or music, it is nevertheless a safe bet that 99%+ % of audiophiles would agree that LPs shouldn't be stored in plain paper sleeves. But their agreement ends there. What type of record sleeve in which to store those precious LPs? Polylined paper sleeves? Rice paper-like sleeves? Something else?

Much has changed in the analog world in the 16 years since the first piece, "Paper or Plastic: Final Resting Place," appeared in the pages of The Absolute Sound. Much hasn't changed. Not only hasn't vinyl faded into the sunset—it's undergoing an unprecedented resurgence in interest. Mobile Fidelity rice paper-like inner record sleeves continue to be produced. Finally, for some reason beyond my comprehension, many audiophile and vinyl collectors continue to store their vinyl treasures in paper or polylined polyvinyl chloride (PVC) record inner sleeves.

What's Wrong with Paper Sleeves?

Back in the what seems like the Jurassic period, records came (un) sleeved in a variety of materials: nothing, plain paper sleeves, glassine sleeves, polylined PVC sleeves, rice paper sleeves, polylined paper sleeves and rice paper-like, HDPE plastic sleeves. For instance, Mercury's albums came in paper and glassine inner sleeves. EMI used a variety of inner sleeves including paper, PVC and later on, their own HDPE inner sleeves. Audiophile labels such as Nautilus and MFSL records used HDPE and rice paper inner record sleeves, respectively. Record companies were slow to abandon the use of paper inner sleeves since these coverings nicely doubled as advertising billboards—or held song lyrics.

Now why should record collectors and audiophiles immediately fling all their paper or polylined PVC record inner sleeves into the nearest trash receptacle (of course die-hard record collectors may want to keep the original sleeves)? Cheap, non-acid-free paper sleeves degrade with time. Paper is derived from the cell wall of plants; lignin, one of the chemicals contained in the cell walls, is unstable and light sensitive and decomposes into acidic products. While bleaching removes the lignin, the paper making process produces other detrimental byproducts such as hydrochloric acid or sulfuric acid. Producing true, acid-free paper (pH >6) requires buffering with neutralizing chemicals.

Paper sleeves are also hygroscopic (water absorbing) and as a consequence facilitate the growth of mold or fungus on the LP. Older audiophiles may remember the original Discwasher record cleaning fluid that used sodium azide to kill and remove these organisms from the record grooves. (Sodium azide was, unfortunately, removed from the market several years later when it was found to react with copper pipes and cause explosions.) As we know from early enzyme based record cleaning fluids from Buggtussel and more recent products from Audio Intelligent and Walker Audio, not to mention two newly released items from Mobile Fidelity and Musical Surroundings, microorganisms lurking in the record grooves contribute to the record's background noise and the occurrence of pops and tics. These various organisms, according to Dr. Bruce Maier, founder of Discwasher, "produce vinyl etching enzymes." (see BAS, vol.3, no. 10, 1975.) Paper sleeves also contain and shed debris that is trapped by "sticky" record mold release compounds. (Note, other particles can also be trapped–and that's a compelling reason to clean brand new LPs.) Glassine paper is no better than ordinary paper because of its hygroscopic properties.

On the other hand, polylined PVC paper sleeves (not high density polyethylene (HDPE) sleeves discussed later) damage the record album when they release or leach acids or plasticizers (chemicals that make the plastic more malleable) onto the LP's surface. Many record collectors have at one time or another encountered an album where the PVC polylined sleeve melded to the record–or left behind on the LP a non-removable, sticky, plasticizer residue that affects playback.

Record Chemistry

So while the choice of record inner sleeve profoundly affects the record surface, cleanliness and playback quality, the biggest barrier to maintaining a clean album and extending its useful pop and tick-free lifetime is the record chemistry itself. A primary static charge is created the moment the record surface separates from mold surface. Briefly, records are a complex chemical mixture including 85% polyvinyl chloride (PVC), 15% polyvinyl acetate (PVA), antistatic agents, dyes, stabilizers (heavy metals such as lead stearate), modifiers and lubricants. PVA, the exact chemistry of which varies among companies, both aids in the flow of vinyl during record pressing and as a plasticizer. Plasticizers play a critical role in softening the plastic/resin. Under normal conditions, stabilizers, of which there are enough to last for decades, act to consume HCl. (One fact that many those who want to steam clean their LPs seems to ignore, is that heat and UV degrade PVC; heat causes the release of HCl.)

As a consequence, records have a primary static charge on the order of 1 x 1013 ohms that attracts and holds like a magnet, damaging particles. Secondary static charges are also created when removing the record from its inner sleeve (or overcleaning an album with a record cleaning machine). Now while audiophile quality inner sleeves treated with special antistatic agents go a long way toward dissipating secondary static charges, they're no substitute in my experience for Furutech's Destat Static Charge Remover gun.

Over the years, many respected authorities in the field including Percy Wilson (one time Technical Editor for Grammaphone magazine), Bruce Maier (Discwasher) and most recently, Paul Frumkin (Audio Intelligent record cleaning fluids), have pointed out that records tend to leave pressing plants dirty and then are subject to a contamination from a variety of sources. For example, Percy Wilson (JAES, 1964) noted that, "trouble due to surface contamination shows up mainly in spurious noises being more obtrusive…" and "certain types of contamination also result in high note loss." Wilson divided record contaminants into three distinct groups including:

-

Hard, discrete particles comprising shed skin cells, soot, dust, grit, textile fluff

-

Fluids such as saliva from blowing on records

-

Condensates such as smoke from cooking or cigarettes

Wilson also demonstrated that a spinning record creates a vortex that sucks dirt out of the air down onto the record. He also demonstrated that this aerodynamic action causes the extent of contamination to vary across the album and "‘pops and crackles' arise in a record mostly at the outside grooves and then at the middle of the recorded surface.' As Wilson states in his article, "between the two there is commonly a quiet patch, as there is also nearer to the label."

There is a caveat to this story for audiophiles with turntables equipped with hard plastic platters employing clamp down or vacuum based platters. Like the records they play, these modern day, plastic platters possess a static charge and attract dust and dirt particles (these metacrylate or acrylic modern day platters accumulate quite a static charge in the dry, New York winters.) Thus these platters must be kept immaculately clean or dirt trapped between the platter and record will damage the LP. John Bicht of Versa Dynamics discovered this effect ages ago and was forced to place a very thin, Bounce-like sheet between the record and platter to prevent damage to the LP.

So where does that leave us? First, records and turntable platters must be kept immaculately clean. Next, once cleaned, audiophiles must use high quality inner sleeves to maintain the record's cleanliness and reduce the album's secondary static charge.

Inner Sleeve Chemistry

The rationale for storing and preserving vinyl records in high quality, chemically inert, inner sleeves includes:

-

Neutralizing the record's static charge and preventing static buildup when pulling the LP out of the record sleeve

-

Preventing the record jacket or dirt from scratching the record

-

Preventing dust from sticking or becoming embedded in the record

-

Allowing the record to smoothly slide in and out of the record jacket (a complicating factor is that record jackets vary in size)

As alluded to earlier, PVC is an unstable plastic and under the right conditions, releases hydrochloric acid (HCl) and plasticizers; in contrast, polyethylene (PE), first known as Marflex (1954) and made famous by the Hula hoop, is considered a relatively inert plastic. PE comes in several densities, the most significant among them being LDPE (low density polyethylene), the most widely used and cheapest, MDPE (medium density polyethylene) and HDPE (high density polyethylene), stabile up to 120oC and more rigid. The plastic's density is determined by proportion of crystals in the mass, packing and layering. As a plastic, PE possesses a number of attributes that make it an ideal record storage material including its inertness, high tear strength, temperature stability, rigidity and good moisture and water repulsion.

Polyethylene plastics, like their LP cousins, are also statically charged. To address this problem, antistatic agents such as polyethylene glycol esters, glycerol monostearate or ethoxylated secondary amines are added to the resin; the antistatic agent's hydrophilic properties (coupled with limited solubility) causes these agents to migrate to the plastic's surface where they act. PE films are also treated post-production with antistatic agents.

The Sleeve Line-Up

Despite searching high and low, I was unable to unearth any currently made, authentic, 12 inch rice paper inner sleeves. Today's all rice paper-like sleeves obviously emulate the slipperiness, antistatic and protective properties of rice paper but they're really made from HDPE.

Truth be told, the perfect record inner sleeve doesn't exist. Polylined paper inner sleeves such as those used by audiophile labels such as Analogue Productions, Classic Records, Cisco Music, etc., have a proclivity to tear in two places. The most common spot is along the edges of the sleeve where the record "bounces" (in particular the bottom of the sleeve). Another problematic polylined area is the round, center viewing window; this site seems particularly prone to tearing when inserting the record into the record jacket. On the plus side, the added thickness of the paper backing prevents the dreaded corner foldover effect, the double sided window allows for easy viewing of the record's A and B sides and the added paper stiffness prevents scratches.

When it comes to rice paper or rice paper-like record inner sleeves, the corners have a nasty penchant to fold-over and expose the LP to scratching. As a result, one needs to be especially careful when inserting rice paper-like sleeves into undersized LP jackets. On the plus side, I have yet to have a rice paper-like sleeve tear along the edges and its slipperiness assists in sliding the LP slide into the record jacket. The paper backing on one side serves several purposes including adding stiffness to the sleeve, and absorbing moisture and any plasticizers or any free ethylene oligomers that might migrate from the plastic onto the record. Compared to paper inner sleeves, with the exception of the EMI sleeves, one can only see the record label on one side because of the acid-free paper backing.

So without any further ado, here's the current line-up of contenders vying for the crown of state-of-the-art record inner sleeve:

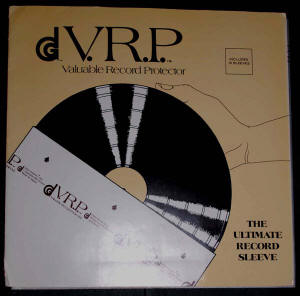

Discwasher VRP (Valuable Record Protector) Record Inner Sleeves (Discontinued)

While no longer commercially available (although some occasionally surface on the Net), the VRP record sleeves are considered by many the "Gold Standard." Designed by Discwasher's then President Bruce Maier, these sleeves were apparently produced in at least three versions.

One of the earliest versions of the more conventional square shape, consisted of a very slippery square sleeve with brown lettering. A second sleeve of probably the same vintage (or maybe even earlier?) with no lettering was used in the Discwasher records. In contrast to the aforementioned sleeve, this sleeve has a rounded bottom like the Nagaoka, and a flap to close the top of the sleeve. Otherwise the design is the same with one side containing a paper lining. This rounded sleeve was then inserted into another heavier, opaque, blue sleeve to aid in protecting and inserting the record into the jacket.

Both sleeves were apparently made in Japan.

Somewhat later on (after Discwasher was sold to Recotron?), Discwasher sleeves manufacturing was switched to Taiwan (where by the way, many today sleeves are also manufactured). The Japanese sleeves are slipperier than the Taiwan sleeves and have blue lettering; in contrast, the Taiwan sleeves are a little heavier and slightly more transparent.

Both appear well made, work well with 200 gm LPs and the inner acid-free paper insert covers almost all of the record and measures identically on each side.

While little reliable information remains regarding the manufacturing of the Discwasher record inner sleeves, some details were gleaned from Jon Risch, who worked for Discwasher at that time. According to Risch, "the originals were ‘rice paper', but later stock was some sort of plastic, but with specially specified characteristics, so that no plasticizers would end up on the record." Risch also remembered that, "Bruce Maier was fanatic about that kind of thing. The original VRP's had no printing on them at all, the later ones had ‘VRP' across the entire width of the upper portion of the sleeve."

As far as Risch knew, "they [sleeves] were only made in Japan;" But, "he didn't know what happened after Recoton bought out the name, they could have done anything."

When it came to materials and construction of the VRP sleeves, Risch recalled that, "the white paper inside the rice paper was treated with a special anti-static chemical; later plastic versions had an anti-static chemical built-in." Risch added that the VRP sleeves had, "extremely smooth surfaces, no plasticizers or materials that could leach-out onto/into the record and freedom from the typical acid content of the cheap paper sleeves used at the time."

Highly recommended if you can find them. The earlier the better.

Discwasher VRP (Japanese) sleeves. Type of sleeve: Rice paper and rice paper-like HDPE. Included with Discwasher records: rounded bottom, no lettering.

Discwasher VRP (Japanese) sleeves (brown lettering): Outside dimension: 12 x 12 inches; acid-free paper insert: 11 15/16 x 11 15/16 inches; Weight: 0.4 oz.

Discwasher VRP Taiwan sleeves (blue lettering): Outside dimensions: 12 x 12 inches, acid-free paper insert: 11 ¾ x 11 ¾ inches; Weight: 0.5 oz.

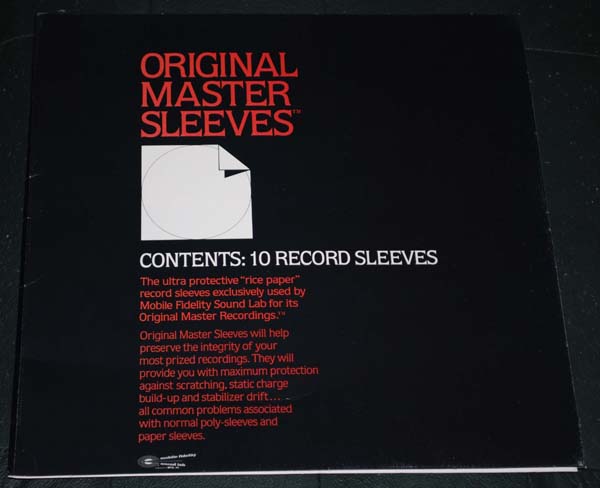

Mobile Fidelity Original Master Sleeves

These record inner sleeves were originally developed by MFSL's founding fathers as part of their concept for a state-of-the-art record. They carefully evaluated every step in the record production process and determined what was necessary to make a state-of-the-art album. For instance, MFSL's cutting system included a Neuman VMS70 Lathe/SAL74 amp (modded) with no input transformer and a SX74 cutting head. Among the reference speakers used in auditioning their LPs were Beveridge Model 2s, RH Labs subwoofers; the electronics included Mark Levinson ML1 and ARC 6 preamplifiers and ARC D110 and Threshold CAS-1 amplifiers. Records were played back on a front-end consisting of Fidelity Research FR1 Mk. 3F cartridge, Fidelity Research 64S arm and Denon table. That's a system I would had love to heard back then!

In the case of the record packaging and storage, MFSL went the extra mile and completely redesigned the conventional record sleeve; the three most important considerations were the record's static charge, record storage and record warping. The earliest MFSL sleeves were rice paper; current record inner sleeves are made from HDPE. To further protect the record, MFSL placed the record containing rice paper sleeves inside a rigid cardboard sleeve for added stiffness and protection.

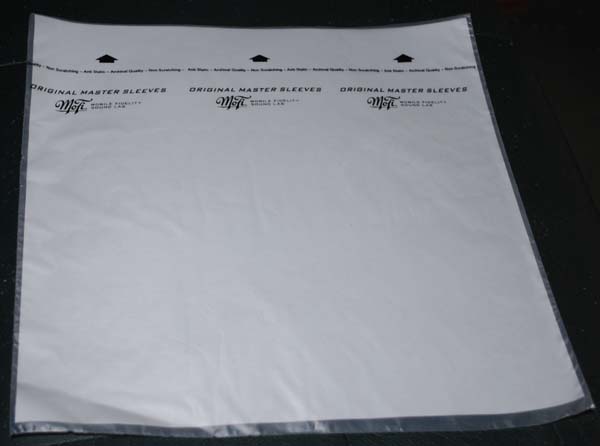

The MFSL OMS are one my favorite and most frequently used inner sleeves. In the course of writing this piece, I found two versions of the OMS. The earlier version (shown below), bought when writing the first article in TAS, has no lettering and comes packed in a cardboard package; the newer sleeves come either in a cardboard package or plastic packages and has the MFSL logo printed across the top.

The newest MFSL sleeves' (shown above) slipperiness and transparency seems much closer to earlier Discwasher VRP than the older MFSL record sleeves. Interestingly, the current MFSL version seems even heavier than the older edition than would be expected by the 0.1 oz weight difference. Like the Discwasher VRP, the MFSL sleeves are well made and I've never had one tear though they like all rice paper-like sleeves are prone to the dreaded corner fold-over effect. 200 gram albums slide in and out of the OMS with ease. The acid-free paper insert is centered, though slightly smaller in the newest versions.

Highly recommended!

MFSL Original Master Sleeves. Type of sleeve: rice paper-like HDPE. Outside dimensions (earlier): 12 x 12 inches; acid-free paper inserts: 11 15/16 x 11 15/16 inches; Weight: 0.4 oz; Outside dimensions (newer): 12 x 12 inches; acid-free paper insert: 11 13/16 x 11 13/16 inches; Weight: 0.5 oz. Price: one 50 pk.- $20; 10+ 50 pks - $15 each.

Sleevetown Ultimate Audiophile Sleeves

The Ultimate Audiophile sleeves are one of the newest and one of the best record inner sleeves on the market. One can easily see many audiophiles liking these inner sleeves because of their sturdiness. All three seams, seem especially well reinforced.

Designed and produced by Tom Murray, a hard core audiophile and record collector, and manufactured in China, the Sleevetown sleeves are according to Murray, "the same as the original Discwasher VRPs." The biggest issue in evaluating the different prototype sleeves according to Murray, "was that of quality control. That included not having the acid-free paper off center or varying in size so the sleeve will fit inside all record jackets." According to Murray, "one other important difference between the Sleevetown sleeves and their competitors is that the seams are die cut rather than being folded over. Each sleeve consists of 2 layers of 1 to 2 mil HDPE plastic (so the plastic stays soft) sandwiched around paper inner sleeve. There's plenty of space inside the sleeve to accommodate all current record thickness including the newest generation of 200 gm discs.

Highly recommended!

Sleevetown Ultimate Audiophile Sleeves. Ordering information: www.sleevetown.com and some stores. Type of sleeve: rice paper-like HDPE. Outer dimensions: 12 x 12 inches; acid-free paper dimensions: 11 ¾ x 11 ¾; inches. Weight: 0.6 oz. Price: 50 - $16.95/100 - $29.95

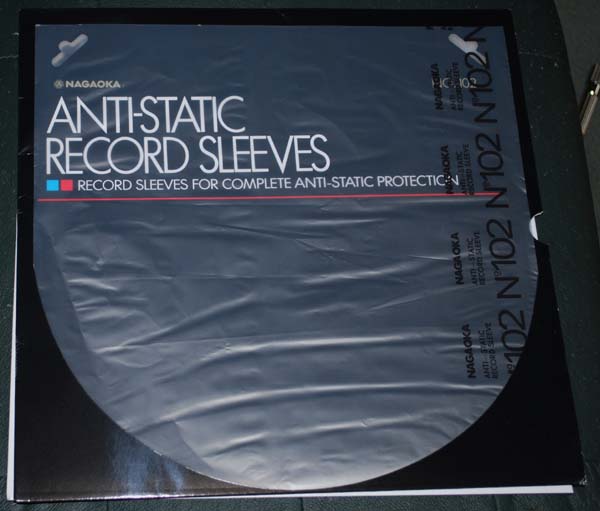

Nagaoka No. 102 Anti-Static Record Sleeves

Just why these record inner sleeves are so highly regarded escapes me. The Nagaoka is the only sleeve in this survey that really can't recommend on either a price or performance basis.

In contrast to the other square sleeves, the Nagaoka features a curved profile to help in sliding the record in and out of the jacket. Despite its rounded shape, however, inserting a record encased in a Nagaoka sleeve into a record jacket without corner foldover, especially in "smaller" record jackets, is near impossible. The only way to insert the sleeve into the record jacket without corner foldover is with the round side in first; this, however, defeats the purpose of the exercise and allows the record to slip out and doesn't really offer any protection against dirt, humidity or other pollutants. Made from HDPE and treated with "a special antistatic agent," these sleeves are far to thin and flimsy to provide any sort of realistic protection against record scratching—especially for thick, 200 gm LPs. The Nagaoka are nearly double the price of the other sleeves on the market and readers are better served using the Sleevetown or MFSL rice paper-like HDPE or the Goldring or Bags Unlimited polylined paper sleeves.

Not recommended.

Nagaoka No. 102 Anti-Static Sleeves. Type of sleeve: rice paper-like HDPE. Ordering information: available on net. Price: 50 - $30.

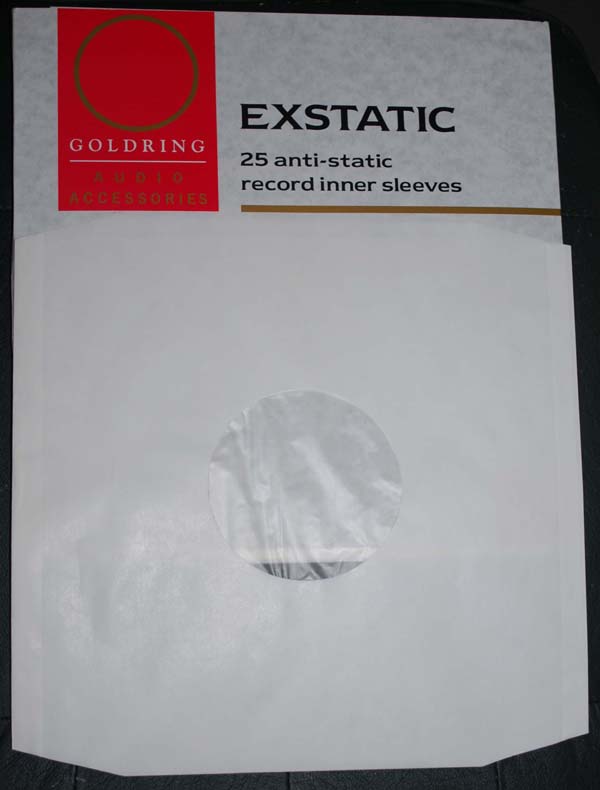

Goldring Exstatic Polylined Record Inner Sleeves

The more I used the Exstatic sleeves, the more they grew on me. Similar in design to the polylined paper sleeves used by Opus 3, these sleeves come with all four corners slightly cut instead of two as found with the Opus 3.

These beveled corners allow for easy insertion of the LP into the record jacket; on the other hand, it does make the LP a little more prone to dirt given the open vent on the bottom of the sleeve. While I haven't played with them long enough, they probably will, like most polylined paper sleeves, have a tendency to tear. One side of the sleeve is slightly taller than the other making LP removal slightly easier but does expose the very outside of the LP. It does cover much more of the LP than the polylined paper sleeves used by AP, Cisco, Classic Records, etc. 200 gm records slide in and out of these sleeves with no problem.

Slightly pricier than the Bags Unlimited polylined paper sleeves but highly recommended!

Goldring Exstatic Record Inner Sleeves. Ordering information: available on net. Type of sleeve: Polylined paper. Outside dimensions: 12 x 12 inches. Price: 25 - $30.

Bags Unlimited Rice Paper-Like Sleeves

These were, especially after my extremely positive experience with their polylined inner sleeves, somewhat disappointing. While the sleeves provided total LP coverage, their construction and quality control much to be desired. According to the website, these sleeves are made from three layers of HDPE. Compared to the other sleeves, these albums were a tight fit with 200 gm albums. There were also large and uneven gaps between the side of the acid-free paper and edge of the record sleeve.

For instance, there was a ½ inch gap on one side of the sleeve; the other side measured in at 3/16 of an inch. The bottom of the sleeve measured a 9/16th of an inch gap compared to 1/16th of an inch for the Discwasher or 3/16th of an inch for the Sleevetown.

The rice paper-like sleeves receive a barely passing grade; the polylined paper sleeves come highly recommended.

Bags Unlimited Inner Sleeves. Ordering information: www.bagsunlimited.com. Type of sleeve: rice paper-like HDPE. Outside dimensions: 12¼ x 12 ¼; acid-free paper dimensions: 11 ¼ x 11 ½; Weight: 0.5 oz; Price includes shipping; 50 - $17.80/ 1000 - $203.00. Polylined paper sleeves: 50 - $21.40; 1200 - $292.30. Availability: On line.

Final Thoughts about Current Audiophile Record Inner Sleeves.

This piece wouldn't be complete without a comment on the sleeves currently used by audiophile record companies such as Analogue Productions, Cisco Music and Classic Records. (MFSL is one exception to the rule since they continue to use their own rice paper-like inner sleeves that completely cover both sides of the record.) These companies have opted for a polylined paper sleeves that leaves a sizeable portion of the outside of the record exposed. (Classic Records much have different sleeve sources since some Classic releases exhibit this problem while others don't.) One side of the polylined inner sleeve measures 12 inches high; the other side, 11 11/16 inches. While this height difference makes removing the LP from the sleeve easier, this gap also exposes a sizable portion of the outer part of the album to damage. In addition, I've had several albums arrive with damaged and torn inner sleeves. With all the polylined paper sleeve choices today, audiophiles would be better served by a different storage medium.

Conclusions

The main take home message from the original piece written 16 years ago still hasn't changed: LPs are becoming more and more precious and irreplaceable. Most of today's audiophile records labels either use rice paper-like sleeves or polylined paper sleeves, but I've run across a few such as Pure Pleasure Records, that still use paper inner sleeves. Current audiophile LPs are being pressed in limited runs and when they are sold out, there's no going back. (At $50 and more a pop, it's not like audiophiles are going to buy back up copies either.) So it's more imperative than ever to take the best care of the LPs one can—and that includes cleaning and storage!

While 30 cents/sleeve seems reasonable, there are several ways to reduce the price/sleeve. First, buy a large quantity of sleeves and get the lowest price per sleeve. Sleeves don't deteriorate and can be stored for years. Another approach is to team up with a bunch of audiobuddies (or audiophiles from a local audio society) and place an order for the largest quantity of sleeves possible. Finally, use the best sleeve possible for the irreplaceable/collectable LPs and use a cheaper HDPE sleeve for the more ordinary albums in one's collection.

So in the end, your final choice of record inner sleeve will come down to the tradeoffs between each type of sleeve's design. You can't go wrong, however, with the rice paper-like sleeves from Sleevetown or MFSL or the polylined paper sleeves from Goldring or Bags Unlimited. If you happen upon a treasure trove of Discwasher sleeves, so much the better!