You are reading the older HTML site

Positive Feedback ISSUE

4

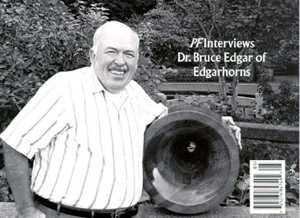

Way back in Vol. 6, No. 5, PF published an interview that our "Audio Minister Plenipotentiary" Dave Glackin did with Dr. Bruce Edgar of Edgarhorn fame. Like all of Dave's work, it's a classic, and gives our readers real insight into the work of Dr. Edgar. We are sure that our PF Online readers will find it to be an excellent resource for those interested in speaker design.

Ye Olde Editor

The Other End of the Single End: Modern Horns Done With Flare

An Interview With Dr. Bruce Edgar

by Dave Glackin

Today, Dr. Edgar is building loudspeakers full time. For more information, or for questions about this article, please contact him at [email protected] or at 310-630-1621.

Dave Glackin interviewed Dr. Bruce Edgar in his home, prior to the 1996 WCES. A follow-up on the speaker system that Dr. Edgar exhibited there, and on his plans for the 1997 WCES, is appended to the interview. It should be noted that Dave is intimately attached to one of the consulting pairs of ears that was used to develop past incarnations of the Edgarhorn, and he worked with Bruce for many years at a federally funded R&D center. However, he had no hand in developing the speaker that was shown at WCES '96. So much for disclosures—on with the interview.

Dave: The single-ended triode craze is really taking off, but the problem is finding high quality speakers to use with those single-ended amps. Bruce Edgar is becoming recognized as a source of high quality horn speakers that don't have the distortions that are usually associated with horns. I've worked with Bruce for many years at The Aerospace Corporation. At the 1995 Stereophile Show, he got many votes for Best Sound in Show and also some votes for Worst Sound. It looks like people were either mesmerized by these speakers or didn't like them—it doesn't appear that there was much middle ground. Bruce, tell us, first, how you got started in this field, and a little about both your musical and aerospace background.

Bruce: When I was a teenager in the mid 50s, one of my first speaker projects was from an article in Popular Electronics about a little corner horn speaker. I now call it a pseudo horn because it used two 5-inch speakers in a quasi-backloaded horn. When I look at that project now, I can see just how much folly and fiction there was in it, but it sounded okay, and at the time I didn't know the difference. I also played trumpet and French horn in high school bands, and so I've always been intrigued by horns. The band experience gave me a sense of how much power is in a real musical instrument, and I used to love sitting in the band just listening to all the instruments playing. Today, horn loudspeakers are the only speakers that I have found that convey the acoustical power of musical instruments.

In terms of education, I went through Electrical Engineering (EE) School at Oklahoma State University in the early 60s. Originally I thought I wanted to go into physics, but a number of physicists in the oil industry that I knew growing up told me that engineers make more money, so I went into engineering. But the problem was I was always the best mathematician among the engineers, so instead of doing the typical circuit theory, my professors wanted me to work with Maxwell's equations and wave propagation. None of the regular engineers liked this, but I did. I ended up doing a Masters Degree at Oklahoma State in antenna research that, interestingly, involved an acoustic wave being excited in plasma by an antenna. Later, I was admitted to Stanford in their Ph.D. program in EE I worked in a very low-frequency radio propagation group that was interested in studying lightning as received by earth satellites. This involved computer calculations and spectrum analysis. As it turns out, the VLF radio frequency spectrum was the same as the audio spectrum, so we used many types of spectrum analysis machines, such as FFTs, tracking wave filters, etc. I learned how to apply them, which later turned out to be a good background for analyzing acoustics and speakers. I did a Post Doc in Atmospheric Physics at the University of Florida where I worked with atomic cross-section modeling for atmospheric species. Then I was hired by The Aerospace Corporation to work in very low frequency research doing some of the same things I did at Stanford. Later at Aerospace I went to a group that worked with small scientific satellites, where I did the planning on how you put experiments together for satellites. With the downturn of aerospace work, I found myself in 1994 having to find another job. At that point, the loudspeaker business was taking off and I said, "Well, if I don't do it now, I'll never do it," so for the past year I've been gainfully employed starting up a business called Edgarhorn and building and designing horn speakers.

Dave: How did you become interested in horns?

Bruce: Originally I was working with box speakers and didn't think too much about horns until about 1978. A group of us from work went to Bill Chater's house and listened to a new ESS Heil speaker that one of them had bought. (Bill Chater later designed the Chater MOSFET amplifier that appeared in Audio Amateur in 1988.) After listening to the ESS speaker, Chater said, "Why don't you guys listen to this?" It turned out to be a folded horn, which was very similar to the Klipsch Corner Horn. I was flabbergasted! I said "Wait a minute, where has all this been? I've never heard anything like this and I'd better find out more about it." I then started doing a typical research scientist thing and tried to find all the scientific literature on horn loudspeakers.

Dave:What came first, your interest in science or your interest in music, or did they go hand in hand?

Bruce: It was both. I was interested in music, but I wasn't all that good a musician. I was a much better singer. I started out in boy's choir and kept on singing all through my teenage and adult years—tenor and baritone in church choirs. But I was also interested in science. I was quite active in science fairs, and won the State Science Fair in 1960 in Oklahoma doing some experiments with high voltage and dielectrics. But I didn't do anything with horn loudspeakers at that time.

Dave: At what age did you start singing?

Bruce: Probably seven or eight as a boy soprano.

Dave:So you were singing for many years and playing French horn and trumpet. You've also done a lot of amateur choral recording.

Bruce: In college, I bought a reel-to-reel tape recorder to record my church choirs. Over a period of years, I was able to get better equipment and my recordings improved. I learned how to mike groups in various rooms. I produced two LP records from my recordings, but that was many years ago. Back in the late 60s, there were many small recording shops that were making their own LPs, and they would do limited issue for choirs and bands. For a modest amount of money, you could make several hundred records and sell them to church members. It was all entertaining and interesting work, and people appreciated the recordings. And some of my recordings were sonically very good.

Dave:You were taking a scientific approach to horns by going out and finding all the literature you could, and learning about horns what had been done in the past.

Bruce: Well, the first thing that you learn if you do a literature search is that there is no one article or book that will give you a cookbook approach to designing and building a horn. I get this question asked all the time, and I have to tell people "Sorry, I don't know of any book or any article that will tell you." At first I would take construction articles that appeared in various magazines and try to reproduce their work, just see how close they were to the exact formula. You discover that there are many compromises, and for good reason. It's very hard to make real horn contours that exact, and in many cases it's not that critical. I analyzed horn designs off and on for quite a few years, until I finally thought, "Well, I need to try one." So, first I tried a complicated bass horn. It was one of these underground K-horn construction plans. There were just too many parts. It wasn't real clear on how everything went together, and I finally had to give up. I said, "You know, this is silly. I should design one, based on what I know and see how it works, " so I designed a little corner horn for a church fellowship hall. The church needed to upgrade their sound system, and I volunteered my services. I built a corner midbass horn that went from 100 Hertz to 500 Hertz and used a Radio Shack driver and a midrange horn for the upper voice range. It didn't sound half bad, but I knew there were many things wrong with it. For one point, the Radio Shack driver was not a proper horn driver, but given the literature, nobody would tell you exactly what kind of driver you should use.

Dave:What year was this?

Bruce: This was about 1981. I wrote an article about it and sent it off to Speaker Builder, which had just started up in 1980, and I had subscribed to it from the very first. Several weeks later, the galley proofs returned by mail, and I was flabbergasted. I had written for a number of scientific publications, and no scientific publisher/editor had ever done that. It takes a number of revisions and comments by referees before a scientific paper is accepted, and it was a pleasure to have an article immediately accepted for publication.

Dave:Yes, a typical amount of time for the Astrophysical Journal, if I remember correctly, was about a year.

Bruce: What I didn't realize at the time was that Ed Dell, the editor, was really starved for good articles. I'd had the experience of learning how to write a good scientific paper, so writing a loudspeaker article was much easier, and I could do it in a much more detailed way than a typical amateur builder. Plus I was paid for it. In my research, I kept coming across references in the British journals to a loudspeaker inventor by the name of Paul Voigt and his Tractrix horns.

Dave:And that was when?

Bruce: That was in the 30s and 40s. Voigt had written a number of articles in Wireless World, but nobody in the U.S. knew anything about them. I was talking to Ed Dell and I said "Do you know anything about Voigt?" and he said, "Yes, he lives in Canada, and I have his address and phone number." Well, I ended up calling Voigt. He was just a very gracious old man, but he didn't want to talk about loudspeakers. He wanted to talk about relativity and physics. He had a lot of strange ideas, and I said to myself "Oh, no, I don't need to talk to another quack."

Dave:Did he have a scientific degree or was he self-educated?

Bruce: He obtained an EE degree around 1920 from the University of London. He was able to give me some information about the Tractrix. Meanwhile I had run across a number of other articles that dealt with the mathematics, so I set about writing an article for Speaker Builder about the Tractrix horn contour. Until this point, all I knew was the exponential horn that you find in every textbook.

Dave:And that has to do with flare rate of the horn?

Bruce: It's all about the horn contour. The exponential expands at an exponential rate, which is the rate at which the area changes as a function of distance and frequency. So, the exponential formula tells you to plug in a frequency and a throat area and expand it out to a desired mouth area. People have been doing this since the early 1920s, when Webster first worked out the exponential horn equation. You find references to exponential horns in all of the magazines, but you won't find any mention of the Tractrix horn. I finally located one article in the early 50s in the Journal of the Acoustical Society, but other than that, Voigt was the only one that wrote about the Tractrix contour. He patented the contour in the 1920s in England.

I talked to Voigt many times over the phone. He would write me letters, and the letters were stream-of-consciousness. They would jump from one paragraph talking about his theory of gravitational forces, then the next paragraph would say, "Back in the 20s when I working for Edison Bell we did this." It was a quite a mish-mash of interesting stuff, so I told him that I would like to do an interview with him for Speaker Builder. He said, "Oh, no, I can't do that now," and so he put it off. What I later found out was that Voigt was one of the most prodigious procrastinators. I said "Well, okay, let’s do it for Christmas." So I called him up at Christmas and he says "No, let's do it after Christmas." So I called him up after Christmas and he said, "No, we can't do it now, I developed a hernia playing with my nephews over Christmas vacation and I've got to go in for surgery." The next week I received in the mail a pack of materials with a letter from his wife, telling me that he died the night that he came home from the hospital from a heart attack. I said, "Oh no, that just blows it." Afterward, I was talking to Ed Dell, and said, "I have many letters that he wrote me, talking about his career. I think I could put together a pseudo interview, a re-created interview based on his letters and articles." It was great fun because it was fact and fiction. I knew the questions that I wanted to ask him, and sure enough there were paragraphs that I found, either in his letters or in his articles, that answered them. I composed an interview, and people at the time were astounded that I was able to do it. His friends in England were even more astounded, because they knew exactly how he talked. When I was working on the interview, Paul's wife, Ida Voigt, asked me to come up later in the year and help her go through her husband's papers. She had invited the same mutual friend that had given Ed Dell Voigt's address.

Dave:Who was the friend?

Bruce: It turned out to be Geoffrey Wilson, who was a Professor of Acoustics at Penn State. His father was Percy Wilson, who was an editor at Gramophone for many years. I went up for a weekend in May of 1981. We went through all his stuff, and he had saved everything. I was able to add a little more material to the interviews for Speaker Builder, but it was just interesting to see all the different things the guy had done. He had designed a 100-Hertz Tractrix horn with his driver. When he was working for Edison Bell in England, at the beginning of his career, he was a recording engineer, and couldn't find any loudspeakers that satisfied him, so he started working on loudspeakers. His idea was that you had to have a big motor and a very light diaphragm to get all the transients. What he didn't understand was that all direct radiators have heavy cones, because they're mass loaded. When he constructed a speaker using a very light diaphragm and a big motor, it sounded very tinny because the magnetic field will actually damp out low frequency response.

The only way that he could figure out to make his driver sound good was to horn load it, but he couldn't understand the mathematics behind the exponential, so he said, "Well, the exponential theory predicts that the wave form going down the horn is plane or flat, but if you look at the physics of the situation, the wave front has to drag along the horn walls. So naturally it's going to be curved. What if I geometrically designed a horn that has curved wave fronts all the way through the horn and see what happens?" So he did a geometrical construction of a horn that would give him curved wave fronts. He said that a draftsman looked at what he had done and said, "Oh, that's a Tractrix curve." The Tractrix curve comes about because if you have one airplane chasing another on a different course, then the chase plane has to change his course to intercept the other plane, and it turns out that's a Tractrix curve.

If you set up the differential equation for the spherical wave fronts traveling all the way down the horn, as I did in my 1981 article, you end up with the mathematical expression for a Tractrix curve. Well, that was all fine, but people said "Do they sound very good?" I later heard a Voigt horn in England, and it did sound fairly good. The driver he designed was incredible. He had to use a big electromagnet with 20,000 turns on it, and design the pole pieces so that he could sustain upwards of 15,000 Gauss across the voice coil, whereas most loudspeakers at the time couldn't get close to half that. He was quite ingenious. He had many patents.

Dave:Bruce, you have quite effectively demonstrated the difference between Tractrix horn sound quality and exponential horn sound quality, which I've enjoyed seeing you do at CES and the Stereophile Show. You had a couple of horns made out of stiff paper, you just picked them up and spoke through them. I wonder if you can easily characterize the differences between the exponential and the Tractrix?

Bruce: Yes, those particular horns were made for me by Bill Firebaugh, the Well Tempered arm inventor. He's also been interested in horns. He showed the paper horns to me. I said, "I've got to have a pair of these." So he made up a pair of horns. They are a round Tractrix horn and a round exponential horn. You talk through them like megaphones. When you talk through the exponential horn, people can hear the coloration to your voice, which is a certain resonant quality that wasn't there before. You talk through a Tractrix horn and you don't hear it. It's completely open.

The explanation goes back to the difference between spherical and plane waves. When the plane waves travel down to the end of the mouth of the exponential horn, suddenly there's a bulge where they exit into space, and that bulge is essentially a discontinuity. So, you have reflections at the mouth, which travel back to the throat and set up a quarter-wavelength resonance condition. With the Tractrix horn, since the waves are spherical going through the horn, they exit the mouth with very few reflections. When I first started building Tractrix horns, I heard this immediately. They didn't have the same horn colorations I'd heard before. I said, "Well, I ought to build all my horns this way," so when I built a 70 Hertz Tractrix Bass Horn (Speaker Builder, 1983), I was in for a surprise. The problem is that the Tractrix is a short horn. If you take the equivalent Tractrix and equivalent exponential horns (same mouths, same throats, same flare rates), the Tractrix horn is shorter. At the low end, the response on any horn is limited by the throat reactance, which peaks at the flare frequency. The exponential horn is long enough that if you can put on a back chamber and resonate it with your loudspeaker at the flare frequency, you can partially cancel out that throat reactance. With a hyperbolic exponential horn, you can cancel it out exactly. With a Tractrix horn, you don't cancel it out at all, so the 70-Hertz horn rolled off at 100 Hertz. It sounded very good, but the problem is that the Tractrix horn response just does not extend to the flare point. There is no way that you can do it, so you have to live with the consequences. Well, for a midrange horn that's not too bad. The 300-Hertz horn that I make turns on at around 400 Hertz, and since its size is not huge, I can build a full-size 300-Hertz horn. It sounds very nice, but it won't turn on until 400 Hertz.

In a bass horn, where you have a very large horn to begin with, you want to get all the low-end response you can get out of it for that volume. People complain enough as it is about how big my bass horns are. The hyperbolic exponential horn will allow you to cancel out the throat reactance exactly and obtain response down to the flare rate and below, so in my designs for my mid-bass and bass horns, I use either exponential or hyperbolic exponential horns. For my midranges I always use Tractrix.

I did the 70-Hertz Tractrix corner horn, using a 6-inch Pyle loudspeaker. I had just read an article by Don Keele that gave the requirements for horn drivers. It was the first paper I'd seen which talked about what criteria drivers must have to power a bass horn. You can get a reprint of it from the Audio Engineering Society [D. B. Keele, "Horn Design Using Thiele-Small Parameters." AES Reprint #1250, 1977]. He essentially said that you have to have a very large magnet and a very light paper cone, which says you have a very low-Qes driver. You can predict the top frequency where the horn response is going to roll off, which is called a mass rolloff. Essentially, the ideal horn driver is a mass-less piston, and when the mass reactance is equal to the acoustical throat resistance of a horn, the horn response rolls off. You can calculate the mass rolloff for any driver, and that's twice the resonant frequency divided by Qes. You can go through the driver catalogs and pick out drivers that will work on horns. The problem is that you discover that most woofers have mass rolloffs on the order of 200 Hertz. It turns out that there is a figure of merit for loudspeakers, which is fs/Qes, which is half of the mass rolloff number. Using that number, you can decide which woofers are good for bass reflex, which drivers are good for sealed box enclosures, and which are good for horns. Well, a sealed box enclosure wants an fs/Qes ratio of about 50, and a bass reflex box wants an fs/Qes ratio of about 100.

If you look through the catalogs, you'll find that 90% of the woofers out there have fs/Qes of 100 Hertz. I can name the number of generally available drivers that have fs/Qes values near 200 Hertz on the fingers of one hand. For a bass horn to go up to 400 Hertz places some pretty stringent conditions on the driver. The only ones I've found that work are drivers made for lead guitars, because of the way they've been historically designed. Guitar players want drivers to give out high sound pressure levels, and they don't really need a response below 100 Hertz, so if you take one of the lead guitar speakers made by JBL or Electrovoice and put them in a very small box, they'll have sensitivities near 100 dB. However, they don't have any response below 100 Hertz, which is okay for lead guitar. What I've found is that most drivers that work well on horns don't work well in other types of speaker boxes.

It turns out that lead guitar speakers, such as the EVM 15L, have mass rolloff frequencies close to 400 Hertz. For a bass horn to match up with a midrange horn, it has to go up that high. Many commercial bass horns haven't gone up that high. People tried to use speakers that were designed for bass reflex and then put in a lower midrange horn. The old University Classic horn used a 15-inch, which rolled off around 200 Hertz, and a Cobraflex 250-Hertz lower midrange horn that had many colorations. Electrovoice also used a reflex PA horn to bridge the difference. Klipsch tried a variety of drivers, but the Klipschorn always had a problem of extending the upper bass horn response. At one point they went to a constricted throat, which they still use, and that helped a little bit. But I investigated the constricted throat in a Speaker Builder article and found that all it really did was change the standing wave pattern. It didn't really improve the upper bass response.

When I started putting together complete horn systems, I approached it the way everybody else had–you have a bass horn, you have a midrange horn, you have a tweeter horn. And so I ended up designing and building a number of 40- and 50-Hertz horns, which have been published in Speaker Builder. In the Audio Club at Aerospace, we had a quarter-size 50-Hertz horn that used a 12-inch lead guitar speaker that worked very well. People said "Well, we'd like to have something a little bit smaller." So I designed an eighth-size version that became the "Show Horn." An eighth size is where the mouth area is an eighth of a horn designed for free space, and if you look at a corner, that's essentially an eighth of a sphere. The idea is that you have acoustical images behind the wall and below the floor that reinforce the low-end response. For a corner horn, you can construct seven other acoustical images that tell the horn, "Oh, I'm a full-size horn." For a quarter-size horn that goes up against the wall, you have three other images that add up, telling the speaker that it's a full-size horn.

Dave: This is up against the back wall?

Bruce: Yes, not against the corner.

I went ahead and built an eighth-size version of my 50-Hertz horn for the 1988 Stereophile show in Los Angeles. Speaker Builder and Madisound were sponsoring a room, and so I said, "We can furnish an amateur speaker system and provide sound for the room." After the show we started comparing the responses of the eighth-size versus the quarter-size. The quarter-size had much deeper bass. The other difference I found was that the back chamber for the eighth-size horn (the Show Horn) was twice as big as for the back chamber for the quarter-size, the larger horn. The back chamber for the quarter-size horn was almost exactly what you would predict for an infinite horn. I think for forward-firing bass horns that a quarter-size always sounds the best, and that's been borne out in practically every experiment. Every time you do an eighth-size horn, the mouth size is not big enough, even if it's in a corner.

Dave: This is the woofer we're talking about?

Bruce: Yes, this is for the bass horn; for the midrange, you always do a full-size horn.

Dave: With every one of your speakers I've ever seen, the mid-range has been the same size as the one we're looking now, right?

Bruce: Yes, I've always used a 300-Hertz Tractrix horn. Now, one of the problems with many of the vintage midrange horns is that the mouth size does not match the flare rate. If you take a look at the response when the mouth size cutoff matches the flare rate, the response is very smooth. Some people designing horns used a 250-Hertz flare rate, but a mouth size of 500 Hertz.

Dave: That frequency refers to the low end of the midrange response?

Bruce: Yes, and essentially it's the mouth size. The way I look at it, if a round horn is the right size, then the circumference is equal to wavelength for the flare frequency. If you make that mouth size significantly smaller, then you get reflections at the mouth, which gives spikes all the way through the horn response. You can hear those spikes. They may not show in some measurements because the spectrum measurements don't have high enough resolution, but your ear will hear them. Discrete frequencies are recognized by the brain because they correspond to speech. If you hear the peaks and they don't correspond to anything musical, you are bothered by it.

Dave: But they're much narrower than the standard resolution of a frequency analyzer.

Bruce: Yes, a third-octave analyzer would have a hard time picking them up, but I've looked at them with high-resolution FFT analyzers. One of the things I learned in doing spectral analysis is that you can let a FFT integrate over time. If there are any spikes in the response of a loudspeaker, it will show up in that integration interval.

Dave: In the power spectrum?

Bruce: Yes, in the power spectrum. It's measuring voltage, and we used to use it in VLF radio analysis to dig very weak resonance signals out of the noise. But if you have any resonances in your loudspeaker response, they will show up. I have measured many commercial horn loudspeakers, and it was amazing to see all these peaks in the response. That's another reason why many old commercial designs sound very harsh, because they have peaks in the response. So, when I set about designing my horns, I worked on the horn profile, matching the drivers and everything to eliminate any big response peaks. People tell me, "Your horns don't sound like horns." Well, there are a number of reasons. I'm using Tractrix for the midrange, which eliminates some of the resonance behavior that an exponential horn has. My mouths are also matched for the right acoustical conditions. I've tried to eliminate all the major sources of these spikes, which come across as colorations.

Dave: And your horns image, which horns characteristically don't do. The Klipschorn was designed for the days of mono, and it simply doesn't image. I think at the 1988 Stereophile show we had some folks come in who were well respected in the field, who said, "Gee, those horns actually image. I've never heard that before." Maybe you can describe a little bit about how your design evolved.

Bruce: Until that point, I was still thinking that you had to spread the sound out. You had to have part of the horn flaring out in the horizontal plane. Everybody else was doing it, so I assumed that was the way that you did things, but I was having a hard time making them image properly. Finally, I had you and a couple of other friends experiment with the horn stack. I couldn't see the forest for the trees. Many times I find that I am so involved in a project, it's very hard to step back and judge it rationally.

One of the particular faults that most speaker builders have is that they always obey Beranek's Law, which states, "The best sounding speaker is the one that you just built." You don't see all the faults immediately. It takes a great deal of experience going through the process of building something, listening to it in a rational manner, and judging what its strengths and weaknesses are, and that only comes with experience. Essentially what I did was to have my friends try all the different combinations and see what works. At that point, we had figured out that we couldn't put the midrange horn on top of the bass horn because that set the midrange too high above your ear. We put the midrange horn in a box on spiked stands in front of the bass horn and set the tweeter on top of the midrange box. The best imaging came about when you narrowed down the horizontal spread, or you put the long axis of the horn vertical. The imaging clicked right in. If you go back and read between the lines of many articles that Klipsch published after stereo was introduced, he had a great number of problems with the imaging of horns. He finally had to put his Belle Klipsch in the center to eliminate the hole. What I've found is that if I put quarter-size horns up against the wall, space them symmetrically with six to eight feet separation, and arrange the midrange horns so that they're more or less at ear level, limiting the horizontal spread, then the imaging clicks in.

Dave: And putting the midranges in that orientation does not seem to have a deleterious effect on any other aspects of the system.

Bruce: The rectangular Tractrix horn always generates a specific sweet point for imaging, but the true Tractrix is a round horn. I've always done rectangular approximations of the Tractrix, but the sweet point for round Tractrix horns is broader. Mainly, you have to keep the pattern well confined in the horizontal plane and not try to spread it all around. If you look at a lot of the old PA horns, they were quite wide and you just can't get them to image.

Dave: Just to clarify that, you said the Tractrix is a round horn?

Bruce: Yes, the analytical formulation for the Tractrix is a round horn. When I first started, there was no way I could build a round horn, so what I did was to convert the circular area into rectangles. The rectangular horns measured quite well, so I was quite satisfied with them. Recently, people have asked me to do a round horn, and so I've had a number of them made for people. I've measured them and there's actually not all that much difference from the on-axis measuring standpoint. There's some difference on the low end. The rectangular horn has a little bump on the low end, which is taken out by the crossover capacitor. If you measure the round horn it doesn't exhibit that little bump, but the rest of the spectrum looks almost the same. Now, the round horn has a slightly different radiation pattern, as you would expect, but in terms of imaging, it may image just a little bit better.

Dave: Is there a particular imaging sweet spot, or can you listen to these speakers from a wide variety of positions?

Bruce: If you're close in, there is definitely a sweet spot for imaging and that comes about because the horns have such a strong forward radiation pattern. At 10 to 12 feet away, you're in the near field response area, in which, if you're slightly off the centerline, one horn can overpower the other, and you don't get as good imaging as you would if you were along the centerline. I recently had an opportunity to put a system into a room that was 25 x 30 feet. When you get 25 feet away, there is no sweet spot. You can move all around, and the imaging is very stable. In fact, it was like you had an orchestra at the end of the room, and you could pick out exactly where everybody sat. But if you're close in, you have to sit right on the centerline to get that sweet spot for imaging. There are many other speakers, such as electrostatics, where there's a sweet spot, too.

Dave: I have a pair of magnetostats at home. I'm listening in the near field and there's one place to listen from where they sound really good. Move off of that too far and the imaging falls apart.

Bruce: Yes, large electrostatic panels tend to beam, which explains that sweet spot phenomenon. If you get off the center axis with horns, one side will overpower the other. I have tried to keep the pattern as broad as I can make it, but most of the time, I've tried to design the horn shapes and the horn mouths to give the best response, not necessarily the best pattern coverage. Many of the commercial horns are designed for PA use, to put sound over a broad area. The constant-directivity horns will cover a certain area very well, but they sound very thin. I've always gone for the best response and then accepted the pattern I got, which works out best for the home situation.

Dave: You've also discovered that 6 dB per octave crossovers seem to work the best. I know that one of the ways you found that out was with a focus group, using those of us in the Audiophile Club at The Aerospace Corporation as guinea pigs in blind experiments, when we didn't know we were being used. (Laughter)

Bruce: Well, I didn't consciously decide to do it that way. I started out using 6 dB crossovers because they were just the simplest to do, and they seemed to work. Klipsch had said in his early experiments that he had started with second-order crossovers during World War II. As his capacitors went bad and he couldn't get any new ones, he changed his crossover to a first order and found out they sounded better, so I started off with 6 dB crossovers. In the mid 80s, Bob Bullock, who is one of the editors of Speaker Builder, came up with a number of articles showing how to design all different order crossovers, and so I decided to try them. I built up some second-order crossovers and put them into the club system. I didn't hear a whole lot of comments about it, but when I switched back to first-order crossovers, everybody came up after the demo in the club meeting and said how good the system sounded. That told me right away that first-order crossovers sound better on horns.

I designed my horns so that the bass horn would roll off at the point where the midrange horn was turning on and the midrange horn rolled off where the tweeter was turning on. Those mechanical rolloffs complement each other, so when you put in a first-order crossover, it essentially acts as a traffic cop and keeps the impedances proper. But the mechanical rolloffs also have a rapid phase change. In the pass band, the horn response is minimum phase, like most loudspeakers, but at the point where they start rolling off, near the flare frequency or at the point where the mass is rolling off the response, the phase changes at those points are very fast. A first-order crossover doesn't mind, but a second-order crossover or any higher-order crossover can't handle all that phase change.

So, just by trial and error, we can essentially confirm what Klipsch found out earlier, but you have to be able to do those experiments to really find out what is the truth, because 90% of the horn literature is pure garbage. It's one author regurgitating what another author said. In fact, one of the amusing things I've found are errors in the mathematical terms that go through several different textbooks, being repeated because they assume that first guy did it right. The following authors just copied the equations and never really checked the math. When people ask me "How do you design horns?" I say that you have to do the experiments. I can go out and buy LEAP software and design a bass reflex speaker, but you've still got to go through trial and error, building boxes with drivers and finding out what things really matter. There are all sorts of things that the textbooks just don't tell you.

Dave: And you've evolved a lot of techniques to improve the performance of your bass horns over the years too, like sand loading, for instance.

Bruce: Well, when I first built my bass horns, one of the club members came up and slammed the plywood box that I built. You could hear it ring all over the place. He said, "You know I love these horns, colorations and all." When I first started out, I was making horns out of plywood because I wanted to keep them as light as possible, just to be able to move them in and out of rooms. But plywood rings, and you can get resonant breakup mode patterns in unsupported horn walls, which will color the response.

Some people use bracing to eliminate resonance, but Barry Kohan of Bright Star Audio came to a club meeting and did a demonstration with sand loading. Briggs used sand loading back in the 50s, but we have much better materials now, and I thought we didn't need it. Well, Barry showed that I was quite wrong about sand loading. He demonstrated that if you mount your speaker on a sandbox and put a bag of sand on top of your speaker, you will improve the bass response dramatically. In fact, he has a little demonstration where he can obtain a 3 dB increase in bass for a little box speaker just by putting it on one of his sand isolation bases, then putting a sand weight on top. He did that to our horn speaker system and I was positively amazed. So we put a small box of sand on top of the bass horn and started listening to the Sheffield Drum Record. We found that there was a sweet spot on top of the bass horn where that sand weight exactly canceled out the resonances. Until that point, you could hear a certain hollowness in the character of the bass drum. When we moved the sandbox to that particular place, the bass changed to where it was very clean. Then I put a sandbox in the bottom of the bass bin and the bass further improved. Later, I was doing some measurements with the high resolution FFT and noticed that I was seeing all these little spikes above where the horn response was well rolled off. It turned out that these peaks weren't artifacts. The response occurred when the path length added up to an odd multiple of a quarter wavelength. I could kill those spikes by essentially putting carpet all over the mouth of the bass bin, which soaked up all the high frequencies and also damped the horn walls. Since then, I have gone to building all of my bass horns out of MDF, which won't ring as much as plywood.

Dave: Do you do that just for the bass horns?

Bruce: No, I do it for everything. The furniture builder that is building my boxes uses high grade MDF, and it's very dead. He puts ribs in between my straight horn and the outside casing, which works very well. Also, when I have unsupported horn walls, I tension the walls together with cross braces. I find that damps walls quite well.

Dave: So that sounds like it's somewhat akin to Michael Green's tunable speaker.

Bruce: Yes, it's the same idea.

Dave: So your first exposure to the public at large was at the Stereophile show in 1988?

Bruce: Yes.

Dave: Since then an awful lot has happened and you've become extremely well known. Part of that, I believe, was due to Sound Practices Magazine starting up in 1993.

Bruce: Yes.

Dave: That's been a great boon to your business and to your reputation.

Bruce: Yes, what really surprised me was that I already had a good reputation. When I would write scientific articles, maybe ten or twenty people would read it, but I found that many people read my Speaker Builder articles. I wanted to keep out of the limelight and didn't want people calling me up all the time, but when I would go to shows and they'd see my name, they'd say, "Oh, you're Bruce Edgar, we enjoyed reading your articles." It takes me a long time to write the speaker articles, but I always try to do a real good job with original research and make them enjoyable. Over the years many people have liked them. They may not build any horns, but they sure enjoy looking over your shoulder to see what you do and how you do it. Well, when Joe Roberts started up Sound Practices, he sent me an issue. In the first issue there was an article about the Altec Voice of the Theater, saying how great it was. I'd heard a number of Altec Voice of the Theaters, and I didn't think they were all that great. They were a good compromise design at the time, but they had a number of flaws. I think I've only heard one that I thought was good and it was highly tweaked. So, I wrote a one-page letter talking about the flaws in the Voice of the Theater design and then said, "Well, this is what I think a good horn system for the typical living room would be." The letter was published in the second issue of Sound Practices. I said that you could do a 100-Hertz horn in about a 2' X 2' X 2' volume and then mount the midrange horn on top and put a tweeter horn on top of the midrange. Essentially that was the genesis of my Edgarhorn system. I had been playing around with 100-Hertz horns before, and I thought they sounded pretty good. One of the things that I learned from the '88 Stereophile show experience is that the upper bass sounded very good in the big bass horns when you pull them away from the wall, but the problem is that the low end response goes away. When you put them back into the right boundary conditions, the bass comes back and sounds very good, but the midbass is not as good.

A number of people read that, and were quite impressed by my vision of what a horn speaker should be. And one of them was Dennis Boyle of Chimera Labs. Dennis has been working with single-ended amplifier designs and was coming out with a high-resolution single-ended amplifier using the 211 tube. He needed speakers to go with this amplifier, so on a subsequent business trip I was able to visit him in Dallas. He wanted me to design and build the best horn loudspeaker system that I could make. I said, "Well, nobody has ever asked me that." (Laughter.) Up until this time, the way I would finance my loudspeaker projects is I would find somebody who wanted that design and would pay for it, or try to talk somebody into it. There have been several readers of Speaker Builder that have made requests. One of them is Fred Ireson in West Virginia, and he stimulated a number of different designs. One of them was the Monolith horn. Amid all these requests, I was coming to this realization that if you do a bass horn that covers all the way from 40 Hertz to 400 Hertz, and then you go to a midrange horn that starts off at about at 500, that there is a big difference between the mouth sizes and the directivities. There should be a more gradual change between the horn sizes. Then there was a big difference between pulling the bass horn out from the wall and putting it back against the wall. It improved one spectrum while lessening the impact of the other.

Dave: Wall placement improved the lower bass, but made the upper bass worse.

Bruce: Yes. So I said, "Why don't I make a very large bass horn that will from the 40 Hertz to the 100 to 200 Hertz region and then have a fill-in horn that will go from 150 Hertz and couple to a midrange horn at 500 Hertz? Instead of doing a three-way system, let's do a four-way system. There really is a good physical basis for doing that. In loudspeaker work, Small has developed the concept of the efficiency-bandwidth product as a constant. So that, for low-sensitivity speakers, say like 90 dB, you can do a very wide-bandwidth system. You can make small two-ways that will cover the whole audio spectrum, but if you go up to high-sensitivity speakers, then the bandwidth shrinks considerably. And so, it's a lot easier to do a four-way horn system. I set about designing a four-way system for Dennis, and what I came up with was a 40-Hertz, quarter-size bass bin that was quite large.

Dave: Bass bin?

Bruce: Bass horn subwoofer; you know, a bass horn bin. It was four feet wide, five feet tall and almost three feet deep. It had a mouth of 16 square feet, which is a quarter size at 40 Hertz. I wanted to keep the path length as short as possible, so I used two 18-inch drivers that rolled off on a horn at 150 Hertz. And I designed a Tractrix full-size horn that was about two feet tall and I think about twenty inches wide, which filled in the difference between 150 Hertz and 500 Hertz, and then I put my regular midrange/tweeter on top of that. The full-size 150-Hertz horn could then be set out well away from the walls, in front of the big bass bin, to give you your stereo information. The whole system literally filled up one whole side of my living room, but it was the most magnificent sound that I had ever heard. The contour was a hyperbolic exponential horn, so the throat reactance was exactly canceled out at the flare point. Below that, there was a very nice, graceful rolloff to 20 Hertz, so you had the best low-end response that I had ever heard from any bass horn. We had quite a few people all over Southern California coming in to hear this horn. I used 1-inch plywood for the bass bin, thinking that the thickness of 1-inch plywood would help control any panel vibrations, but it still had some problems, which were only rectified by bracing and sand damping. It's now at Chimera Labs in Dallas, where it just fills the place with sound. Dennis Boyle has people coming in from all over the world listening to it. The problem is the bass bin is still a little bit big for his customers, so he's trying to size it down.

Dave: Did you investigate any other bass horn designs?

Bruce: In between the Show Horn and the bass horn I did for Dennis Boyle, I did the Monolith horn, in 1990. I had been playing around with horns that would exhaust onto the floor. I did a 40-Hertz bottom exhaust bass horn for Fred Ireson that I published in Speaker Builder in 1993. I called it the Monolith horn because it was so large and it reminded me of the monolith from the movie 2001. Because the mouth was very close to the floor/wall interface for a bottom-exhaust bass horn, I found that I still got very good response right down to the flare frequency, even for a one-eighth size bass horn. My big problem was that if you had a wooden floor, the sound went right through the floor. Several people who have built the Monolith horn with wood floors have found that out. The only way that you can cure it is to mount the base on a spiked platform and then sand-load that platform. I've tried it in a number of other different situations and it works very nicely. The best is a concrete floor, but there are as many people who have wooden floors as have concrete floors. I have a wooden floor, and I've rued the day that I allowed my contractor to build it for me, but I've found various ways, such as the sand damping, to get around that problem.

In all of these different horn designs, I've tried to make each a different experiment so I could find the real strengths and weaknesses of that particular design. Depending on the application, I can go back to one of my experiments and say, "I think this would work in this particular application," whereas in another case it wouldn't. You have to build up a wide base of experience because you never know what the customer will want, and you have to come up with the exact solution for his situation. It's something I enjoy doing. Although I don't always come up with the best solution right away, eventually I'm able to come up with something that does work. The problem with horns is that you still need a large room for them to work properly. Some customers have asked about putting horns in a very small room, like 10 x15 feet or even smaller, and I have to tell them I can't recommend horns for a room that small. You need a larger room, and the bigger the room the better because horns just sound better in the far field, unlike direct radiator speakers.

Anyway, in 1994, Joe Roberts of Sound Practices said, "I've got a Lowther 6-inch driver which I'd like to put on a midrange horn," so I made up a pair and on a business trip to the Washington area, I dropped it by. He put it on and just fell in love with it. Then he clued one of his other writers for Sound Practices, Herb Reichert. Herb said that he would like to hear some more of my horns. So I had an extra set of midrange horns with Dynaudio drivers, so I sent him a pair and he just went ballistic. He said this was the best thing he'd ever heard. With that good word in Sound Practices, all of a sudden I was deluged with requests from people for midrange horns. I asked people what they what they were going to use for the midbass under the midrange. They said, "Well, we're going to use a petite Onken enclosure, that seems to be the standard practice." And I said, "Well, how about a straight midbass horn?" I'd talked about it in my second letter in the second issue of Sound Practices. So I started experimenting and came up with an exponential horn with a length of 16 inches and a mouth size of approximately 20" X 21". With the back chamber, the total depth was about two feet. You could stack a midrange horn on top of it and time-align all the drivers. In '94, I started making up 100-Hertz horns for people, and they were enjoying them. Ed Bellichi at Positive Feedback got a pair of them and wrote a review. They filled in a critical midbass area and did everything that I wanted. Then I looked at options for low bass, but people just can't put in a big bass horn, so I thought there are some good powered subwoofers that could fill the bottom end. At the beginning, I thought this would work fairly well, but it was really a stopgap action.

Dave: That's what you tried at the ‘95 Winter CES.

Bruce: Yes, I was given an opportunity to supply a horn system for the Vaic tube people at the '94 CES. Unfortunately, I only had about a month to put together a system and get it tweaked up. It was a good learning experiment. I received many comments, both good and bad. The Stereophile reviewers said that it had too many colorations, and they were right.

When you put on your products in the public forum, you find out what the problems are very quickly. It's a very hard lesson, but that's the only way that you can get quick feedback. You're in different rooms, which give all sorts of problems, but on the whole I saw it as very positive. Many people had been wanting to see these horns. The horn enthusiasts were saying, "Hey, this looks good." The detractors said that you're still not there. It told me what areas I needed to improve. After the show I had one group of guys in the Los Angeles area that came by to hear my 100-Hertz horn system. They had been building amplifiers, and needed a good speaker system to go with them. They liked what they heard, so they bought my prototypes from the show. They took them home and stripped out all the wiring and crossover components, and started all over again, experimenting with wire, different capacitors, and inductors. About a month later they called me up and they said, "You should come hear your speakers now." I went over there, and I was positively amazed. They sounded so much better than what I'd heard before, and they showed me what they'd done. Essentially they put in better capacitors and changed the wiring. Before, I took whatever wiring I had and used it. Sometimes when I'd wire up a system, it sounded pretty good, and other times, well, it didn't sound quite as good as I remembered from the previous case. I couldn't exactly track everything down. Well, these friends showed me that if I used solid copper wire and paid attention to the directivity of the wire, then the problems I was having with the speaker system went away, and the sound was tremendously improved. They also didn't like the Polydax tweeter, and I had received negative comments at the CES about it. I had an Italian tweeter made by B&C and hadn't had time to really try it out. They liked the B&C D-32 tweeters. Well, I supplied—re-supplied—many customers that have bought my midrange and 100-Hertz horn systems with the tweeters.

The Polydax had some nasty peaks in the response, but it's very hard when you have acoustical peaks to take them out by equalization. You really have to spend time with each individual speaker, listening to it and tweaking this and that. The next speaker you get may not be quite the same, so you end up tweaking every speaker. I would rather correct problems acoustically than trying to correct them in the crossover. I think you're essentially band-aiding with crossover corrections. The Polydax used an exponential horn with a big bullet phase plug. When the horn came out to the faceplate, there was just an abrupt right-angle transition to the mounting flange. The more I started thinking about it I thought, uh oh, it's the same old problem with the exponential horn. Then I looked at how this Italian tweeter was designed. It had a much fatter phase plug in the center, and the horn itself had a much gentler transition to the flange, almost like a Tractrix, so you didn't have these reflections at the mouth. However, lately the B&C tweeters have been hard to obtain, so I have been using the SAMMI bullet tweeters, which also sound good.

Dave: So for the Stereophile Show in April of '95, you incorporated all of the improvements you've described, right?

Bruce: Yes, I used the improved tweeter and the solid copper wiring. Also, we tested different capacitors and found out that the best sounding capacitors in my particular system were made by Siderealkap. They seemed to have the lowest coloration of any of the capacitors that we tried. I also had a professional furniture maker build up the horn with 1-inch MDF. I was still using an NHT-amplified subwoofer to go with it, to augment the bass below 100 Hertz, but there was still a vast difference in character between a direct radiator subwoofer and a horn. You can equalize the system so that you're getting the same levels out of both systems, but the character of the sound is just vastly different.

Dave: You just don't get the sensation that air is moving at the very low frequencies.

Bruce: Yes, the problem is that to move air below 100 Hertz requires an array of woofers. The horns have such low distortion that if you try to put a direct radiator subwoofer with them, you hear all the distortion coming from the subwoofer trying to keep up. So after the show, I set about designing a horn subwoofer that would be active below 100 Hertz. It's a variation of my monolith design. Because I don't have to worry about response above 100 Hertz, I don't have to be as exact in doing bends. If you're trying to build a horn that will go up to 400 Hertz, you have to eliminate as many 180-degree bends as you can, and then you have to pay special attention to all the reflectors at the corners. At low frequencies, as one acoustics professor told me, "It's just like a fire hose, the water just goes wherever the fire hose goes." In the folded horn, the sound goes where the folds take it. The problem is that above 100 Hertz, the phase differences and multiple paths lose the high frequencies.

To go with my 100-Hertz horn system, I have a center channel subwoofer horn that exhausts on the floor. I have it on a raised, mass-loaded platform so that I don't have problems with wooden floors, although a concrete floor helps. Much of the bass information, even with bass drums, is coming out of the 100-Hertz horns, but the depth and feeling with low bass comes out of the bass horn. A bottom exhaust horn spreads out the sound horizontally. We found that this destroyed the imaging with the midrange horns, but it makes a great center channel woofer because it is omnidirectional. For 100 Hertz and below, you just don't need that much directional information, and I find that the two systems work very nicely with each other. You get a very nice sensation of a wide soundstage and the bass impact that you want.

Dave: I heard it today for the first time, and it certainly sounds much better integrated than the system did at either of the shows. And it has the effortless dynamic range of live music, which I think is exceedingly difficult to capture on any other kind of speaker system.

Bruce: Yes, though there were some people at the show who didn't like the direct radiator subwoofer. I don't blame them, but they just totally turned off. I've had a number of people listen to the system and tell me, "I have been through four or five different speaker systems," and start listing the expensive speaker systems they've had. With each one, they finally just had to give up and sell it, and go on to the next. Then they heard one of my horn systems and said, "This is the only system that I can listen to." Another interesting thing that I hear from customers is that when they get my speaker system installed, they have to go back and listen to their whole CD or record collection because all their favorite source material now doesn't sound very good, and the material that was unlistenable before now sounds pretty good. My explanation is that the unlistenable records had a wide dynamic range, and the original speaker system couldn't handle it. Now that you have all the dynamic range that you ‘d want, suddenly the record that was breaking up your older speaker system sounds live, and the records that you liked before sound very compressed. I have to go through many CDs and records to find good material to play on my system, because if the material is compressed it will sound lifeless.

One of the other interesting experiences is to hear various pieces of electronic gear through the horn system. Before the single-ended amplifier revolution I was using solid state gear–Bill Chater's MOSFET amplifier. When Joe Roberts started publishing Sound Practices and advocating single-ended amplifiers, I asked him if he knew anybody that had single-ended amplifiers in California. Well, he gave me a couple of names, and I had one guy bring over his home-built amplifier. At first it sounded pretty good, but then I started hearing a certain amount of muddiness. I thought something was wrong with my speakers, so I finally dragged out my old MOSFET amplifier, plugged it in, and everything sounded good again. My experience is that horns are a double-edged sword. They are very, very sensitive, and it doesn't take a whole lot of amplifier power to get good sound out of them, but that watt or so of energy needs to be extremely clean because if there's any distortion in your electronics chain, it will show up. I think one of the reasons that horn speakers have gotten a bad rap is that the electronics associated with them were not all that great. Sure, they had problems with response peaks, but I think the electronics were also part of it. As the single-ended amplifiers have improved, my horns have sounded better.

Dave: How did you connect with Electra-Print?

Bruce: I've had a very good working relationship with Cy Brenneman and Jack Elliano at Electra-Print. One day about two years ago, they called me and said, "We've heard all about your horn system and we've got an amplifier we want to try." It was a mono push-pull amplifier. It sounded very good on the horns. When the opportunity came up for the '95 CES, I asked them to supply an amplifier for my horn system. Since the Vaic people were sponsoring a room, they modified their newly developed 300B amplifier for the Vaic tube, and it sounded pretty good. We worked between the '95 CES and the '95 Stereophile show to correct the problems that had shown up at the January show. Everything came right together right before the show, and we were all positively amazed at how much better the amps and speakers sounded. People at the show said, "It sounds great, it must be those horns," and I said, "No, it's the horns and the tube amplifiers." The Vaic tube is one of the cleanest tubes I've ever heard, better than any 300B. I am at the point now where I can pick out the distortion in a 300B amplifier because I've heard the difference.

Dave: And in fact, we're sitting here now looking at a prototype of an Electra-Print preamp, which I would guess we'll be seeing at that show?

Bruce: Yes. One of the nice things about the cooperation between us is that for every improvement that the amplifier people do, it shows up immediately on my speakers, and that allows me also to listen more closely to my speakers and identify things that I can improve. It's a very synergistic relationship.

Before, I'd been more or less working in isolation, and progress was slow. When you get feedback from customers and collaborators, progress goes quickly. There's a natural enthusiasm that will show up. Before, I would work on a project for a year or so and not get a whole lot of feedback. Now I get feedback immediately because everybody hears about my latest project through the grapevine, and they all want to hear it. With the new horn subwoofer, everybody's coming by, taking a listen, and hearing all the improvements. That's the way it should be.

Dave: I can certainly hear them on the Sheffield Drum Record. We were listening to that just before the interview. It's a record I am intimately familiar with, and it really sounded good. The bass is there in this system likes it's never been before.

There are a couple of additional topics we wanted to cover—the Dynaudio midrange and the difference between folded and straight horns.

Bruce: When I started on the midrange horn in the early 80s, I didn't have a whole lot of money to spend on drivers. A local electronics store loaned me a number of different cone midrange drivers to try on the midrange horn. I had seen cone drivers used with midrange horns in a couple of English articles in Wireless World, and so I thought that this was a pretty cheap experiment. I really didn't have the money to invest in a big compression driver. So, the ‘85 Speaker Builder article on midrange horns used several 5-inch cone drivers, a 6-inch driver, and a couple of dome drivers. For the most part, I found a couple of cone drivers that were good on horns, but I didn't find too many dome drivers that had good response. One of the problems is that most drivers are mass loaded, and don't do well on horns. 99% of the load a direct-radiator speaker sees is the mass of the cone. It's a reactionary load, and less than 1% of the input power comes out as sound. If you put most midranges on a horn, the response looks terrible.

I’ve had people write to me and say, "I have this driver, will it work on your horn?" I could usually tell them that it probably wouldn't. When I looked at the Thiele-Small parameters of the few drivers that worked, then calculated their mass rolloff on a horn, they got response way above the calculated mass rolloff. The response was out to 5 kHz, and the mass rolloff was about three hundred Hz. I said to myself, "What gives? This violates the laws of physics." Well, being an experimental scientist, you have to accept what you measure, and then you have to start looking at possible explanations. After delving into the literature and discussing it with people, I found out that the drivers that worked well on the midrange horn had very tight suspensions. In his book on acoustics, Morse talks about the case of a drumhead on a timpani, and concludes that you will only get circular breakup modes on that round diaphragm. When you have circular breakup modes on a speaker, they will excite a horn. With breakup modes that divide up into 90-degree quadrants, the horn response goes away. The 5-inch drivers with very stiff suspensions were made that way because speaker manufacturers found it to be an easy way to extend the high frequency response. Once a cone starts breaking up into those 90-degree pie wedges, your response just breaks apart. If you look at most loudspeaker responses, they're fairly smooth at the low end and in the middle, then at the top end you see these jagged peaks. The cones are breaking up into all these different modes. If you make the speaker suspension-dominated, then you can push that breakup region further out in frequency.

The first driver I found that worked was the JBL LE5. I found a couple of other drivers that worked, then wrote the article. I had one customer suggest trying the Dynaudio D-54. I haven't had too much luck with dome drivers because they tend to be well mass loaded. He sent me a pair to try on my horn and I was positively amazed. This driver had none of the response peak problems that I'd run into with the four- or five-inch cone speakers. I could couple the D-54 directly to the throat of the horn. For most of the cone speakers, I had to gap the throat to reduce peaks at the low end. Ever since that time, that's been my standard midrange driver. Other drivers, such as the LE5, seemed to have a more forward sound, whereas the D-54 seems to be a little bit more laid back, but after listening to the LE5 over a period of years, I found it to be a little bit hard, and the D-54 seems to have less listening fatigue.

Dave: But the Dynaudio has been your standard for about the last ten years?

Bruce: Yes, and I haven't found a similar driver. If you listen to it without a horn, it sounds very thin because it has 96 dB sensitivity, which is much higher than the normal midrange. Dynaudio makes it primarily for professional high-efficiency speakers. With higher sensitivity direct radiators, you lose the low end. That's the reason why, when people put a bass driver with 98 dB sensitivity in a reflex box, they ask, "Where'd the bass go?" The problem is that in large magnet speakers, even with heavy cones, the magnet system will damp out the bass. The only way you can restore it is to horn load it. So, probably the highest sensitivity for a full range, audiophile direct-radiator system, is around 93 dB, and that seems to be where the market is concentrating for high-efficiency direct radiators.

We've done power measurements with the horn system, and for the most part, the system will loaf along at a couple of hundred milliwatts of power. In fact, it's very hard to get a watt into it. A good loud sound level is only about 50 milliwatts in acoustical power. People have a hard time comprehending this, but actually air is a pretty poor conductor of sound. In fact, a jet airplane engine is essentially 1 acoustical watt. A loud sound in a living room is about 50 milliwatts. Well, if you have a horn speaker system that's maybe 25% efficient, the amp only has to deliver 200 milliwatts to the speakers, which corresponds pretty much to what I've measured. It's amazing how little power goes into a horn system, and I think that somewhat explains why wiring makes a difference. If you just have copper wire, the amplifier sees a very low resistant path to the speakers. When you start putting other metals like silver and copper together, you may see contact potentials between different types of metals at these very low power levels. When we tried silver, it seemed to have a colored sound.

This is only my conjecture right now, but when you go to a direct-radiator system with a 100-watt amplifier, you can use different metals because you've got so much current going down your speaker line. Most of that power is just heating up the voice coil, but you’re still only getting 50 milliwatts of acoustical power at your listening point. People don’t usually think of acoustical watts, they think of amplifier watts, as a horsepower thing.

Dave: Yes, it's a scary thought. My home system is bi-amped, and if you add up both of the left channels of both amps, you have about 450 watts per side. It's scary to think how little of that is coming out as acoustical power.

Bruce: From an efficiency standpoint, horn speakers are a much more logical way of going. I don't recommend it for everybody. For me, they're the best sounding speakers that I can make. I've heard many good direct-radiator speaker systems, so everybody's got their own way of doing it, but if you're going along the single-ended amplifier route, you will have to try horns. Some people have tried other horn systems, and want to upgrade their systems with my midrange horn. I've had Altec owners buy my midrange horn. They call me back and complain, saying that it doesn't sound like a horn (laughter), or it doesn't have the bite that I'm used to. I say, "Well, live with the horn for a month and listen to your Altec mid horn again." Most of the people come back and say, "I did what you suggested and listened to the old Altec, and I can't stand it anymore." They're essentially obeying Heyser's Catastrophe Theorem. Your listening experience is on one level, then you make a discrete jump up to the next level of experience. If you try to go back to the lower level, it's very hard to do. The same thing happens with sports cars, cameras, wine, etc.

Dave: Don't I know it.

Bruce: We all go through this. Audio gear and speakers are no exception.

Let's talk about straight horns versus folded horns. I have built both. In the beginning, I thought that the secret of designing a good horn was to come up with the optimum folding configuration, but after a number of experiments with folded horns and straight horns, straight horns sounded the best, especially for the upper frequencies. The higher frequencies, above a couple of hundred Hertz, don't like folds. They change phase, have reflections, and have an irregular response structure due to reflections. There's a myriad of problems, but if you have a straight horn, the sound is cleaner. You have an unobstructed wave front that is not bent out of shape coming out of the horn. The negative side of straight bass horns is that the dust cover of the speaker can see the outside world. In a long folded horn, the high frequency sounds coming off the dust cover are lost in the folds. There are high-Q resonances due to the breakup in the dust cover. The dust cover on a 15-inch Electrovoice is four inches in diameter. The high frequencies that radiate off the dust cover are much above the mass rolloff, but they can still be pretty significant. Gluing a big thick felt pad to the dust cover will damp out a good deal of the peaks. The same phenomenon happens when you have a midrange cone driver in a midrange horn. The round button dust cover produces little spikes running well above 5 kHz. Compression drivers don't have these problems because they have a phase plug, but compression drivers create their high sensitivities by essentially forcing the air through very small constrictions. I think you can create more air overload distortion that way, rather than with the large throats and lower efficiencies of my D-54 horn.

Dave: I'd certainly like to thank you, Bruce, for sharing your knowledge and experience with our Positive Feedback readers. What's the next step? What do you think is in store for Edgarhorn in the future? There's been a pretty continual evolution over the last fifteen years or more.

Bruce: Well, there are two areas. I've been doing experiments with round horns. I've done 300-Hertz, round midrange horns for a number of different drivers such as the Altec and the TAD 2001. I'm also looking at doing some cheaper horn systems. I've had a number of people at the Stereophile show say, "We know you can do the very expensive horn systems, but can you do a less expensive system?" so I've been doing some prototyping, going back to some work I used to do a number of years ago. If I used a 5-inch cone driver and put it on a 5-foot long folded horn, I can do an 80-Hertz horn in the same volume that it takes for my straight horn. I was able to find a number of cheaper drivers that would work on the bass horn, on the midrange horns, and on the tweeter horns, so that I can keep my driver costs under about $200. For my other systems I can spend $200 on just one woofer, so I thought that was quite an achievement. I found a 5-inch JBL woofer that's used in a professional, near-field monitor that has very high sensitivity, about 96 dB. I have another 5-inch JBL driver, similar to the LE5, that works well on a midrange horn, and a commercial bullet horn tweeter for the top end. I can fit all this into a box that's about 19 inches wide and 18 inches deep and about 40 inches high. In fact, because the bass vents out the bottom, similar to my monolith design, you can get closer to it, and so it does work nicely in a small living room. It's priced so that somebody buying a single-ended amplifier kit can spend a comparable amount of money for a horn speaker system.

Dave: Have you been approached by other companies about your horn designs?

Bruce: Yes, I have. The problem is that, as one author has said, "Compromised horns get compromised results," so I have to be very careful about compromising my designs to fit somebody's market concept. This is why I've elected to do horns on my own, because I've found that in a large organization, the marketing departments dictate what they want to sell. Customers ask me to do specialized designs for them. I can tell them, "I don't think it'll work" or "Yes, I think it will work," but if a marketing department says, "We want this product," they won't accept "I don't think it'll work."

It's a harder route to go because you've got to finance everything yourself, but I find it's the only way that I can assure that customers are going to get the best sound that I can produce. I'm trying to satisfy my own desires to come up with the best-sounding equipment at a reasonable cost, and most audiophile want that, too, but horn speakers require expensive drivers. It is very easy to move into the professional driver category, where you can easily spend $500 to $1000 for a single driver, and then you have priced yourself out of the market, so I'm trying to put together reasonably-priced products that people can use with their low-power, single-ended amplifiers and come up with satisfying sound.

Dave: Where can our readers contact you for more information, if they'd like to talk to you or discuss ordering a system?

Bruce: They can call me at (310) 370-1302 or fax me at (310) 371-8085, or write me at P. O. Box 1515, Redondo Beach, CA 90278. I find that half my work is talking to customers, educating them about what horns will and won't do, and how they can integrate them into their systems. Many people don't have the foggiest notion of how they work. I’ve spent the last fifteen years trying to figure out how they work, and I like to communicate my knowledge to people. I find that they respond better to my products once I give them good information, but I can't claim credit for doing it that way. Voigt did the same thing. He loved to talk to people, too, and to explain how this all works. Many manufacturers won't do that. I find that because there's so much misinformation out there about horns, the only way that you can change that around is to talk to people.

[The original interview ended at this point. The following addendum was recorded following the 1996 WCES.]

Dave: Bruce, you exhibited a new loudspeaker at the Winter Consumer Electronics Show in Las Vegas which is quite a radical departure from your previous loudspeaker designs. Can you tell us a bit about how you came up with this design and how it differs from your previous work?

Bruce: I knew that European horn systems were going to be exhibited, and I thought I needed to be able to compete with them. It's something that I have been thinking about for a long time, but never had enough gumption to try. People have been asking me, "Why can't you do a two-way horn design?" Well, I can, but the driver cost is much, much higher, so my concept was to make a sculptured, 50-Hertz bass horn and put a round Tractrix horn, powered by a compression driver residing in the lip of the mouth. I thought about it through the fall of '95 and did a couple of preliminary drawings. I decided in December that I'd better get busy, and built an MDF prototype. I thought I would have my furniture builder build it, but we were running out of time and my plans were not all that detailed to let him do it, so I worked for two weeks solid before this show and built the bass horn. I about killed myself in doing it, but basically the bass driver, a 15-inch Electrovoice, sits up high and fires downward and then you have a gentle right-angle turn and the mouth of the bass horn comes out. My furniture maker lathed out the round Tractrix horn, and it was literally put together at the last minute, and was ear-tuned at the show. It's basically a design that I knew would work, and it was just a matter of voicing the speaker. With a two-way system, there are not that many variables to worry about. It turned out to sound quite good, especially when you compared it to the more expensive European systems that don't have a bass horn for the bottom end. They're using either an isobaric or double-chamber vented boxes.

Recently, at the urging of a customer, I tried out the TAD 2001 1-inch compression driver on my round horn. It has to be the best horn driver ever made. The response has great transparency and depth. Most of the 2-inch compression drivers have no depth of image at all. The TAD 2001 is now incorporated in my System 50.

Dave: What are your plans for CES ‘97?

Bruce: I will have speakers in several rooms. There are several other amp builders that now want to use my horn system, so we'll display the budget System 80 and my System 50. We're thinking about putting in a very large bass horn in another room. People will have quite a wide range of horn systems to listen to, so I'm quite excited and looking forward to that.