|

You are reading the older HTML site

Positive Feedback

ISSUE

22

An interview with Max Townshend of Townshend Audio -

A Manufacturer's Perspective on Cryogenics This is the third in a series of interviews with various people in the cryo-industry as to the what's and why's of cryoing - more to come!

So what's the deal with cryogenics? Cryogenically treated components sound much better than non treated components and the difference is NOT subtle. Anyone who tells you otherwise is either ignorant or has a vested interest to say otherwise. How did you get into this? Keith Howard of Hi-Fi News alerted me to this about six years ago. What is your background/history in audio? Townshend Audio has been developing high fidelity audio system components and accessories since the 1970s. Our development and introduction of the world's first Parabolic styli and phono cartridges brought us to the forefront of hi-fi thirty years ago when the only sources for true high fidelity sound in our homes were vinyl records and FM radio. Through the 1980s we developed our own amplifier components and—of course—revolutionary The Rock and The Rock Reference turntables with Excalibur tonearms. Today these record players are highly sought after amongst audiophiles all over the world. Such is the demand from record collectors for the state-of-the-art transcription delivered by 'Rocks' that a Rock MkV is currently under development. Also 'on the drawing board' is a new Rock Reference Master turntable. Designed to be the last word in vinyl replay it will incorporate remote-control adjustment of stylus rake angle and dynamic overhang adjustment.

Fundamental to our advanced monitoring system at Townshend Audio is total isolation from vibration, incorporating Seismic Sink and Versatile Seismic Sink Stands (read our review here) to eliminate all deleterious colourations caused by vibration in active and passive components. Furthermore impedance matched cables are used throughout the system with Deep Cryogenic Treatment (DCT) of all internal wiring and external system cables for maximum transparency from source through to loudspeaker. Explore this site to discover how Townshend Audio's Isolda DCT cables and equipment racks incorporating vibration isolation have won numerous Awards and accolades from the high-end specialist Press in recent years. Can you take us on a step-by-step process on how you cryo something? Many people that employ cryogenics to audio components use the traditional method of treatment. This is slow ramp down, long soak, and long return to ambient temperature. We used to use this process; however in conjunction with our processor we have developed treatment parameters that are more suitable for audio applications. These parameters have been developed over a period of time with the empirical evidence supporting our findings. Therefore we have to keep these parameters as proprietary. Are there different ways or methods of cryoing? Yes. Often cited and still used is the three stage processing technique; i.e. slow cool down, long soak, and slow return to ambient. This technique is great if you are trying to precipitate cabbies in tool steels, and yes it will yield good results sonically. However, one of the side effects of this technique was the increase of micro- hardness levels.

We developed a more refined and suitable treatment parameters for copper and silver cabling. Without divulging too much of our proprietary treatments, essentially what we do is drop the temperature of the material being treated to a certain temperature, which we call a critical temperature. At that temperature and at cryogenic temperature we enter into a more dynamic treatment cycle. Essentially we start a series of rapid temperature changes. This dynamic treatment parameter has a two fold improvement than that of the conventional treatment of cryogenic cabling.

What actually happens to the item when it is cryoed in terms of the material itself?

How does this translate to what we hear? The change is most profound! So much so that Townshend Audio have applied Enhanced DCT to as many parts of the Townshend Audio system as possible, including all interconnects and speaker cables, the connecting wires and PCBs within the TA 565 Universal Player, the forth-coming Townshend Audio preamp and power amp and in the internal wiring of the Glastonbury III speakers along with the voice-coil wire, the tinsel lead-in wires of the drivers and the crossover inductors. Now, just substituting one foot of untreated copper wire or even DCT treated silver wire causes a marked and easily audible degradation in sound. (DCT treatment of silver doesn't sound nearly as good as EDCT copper) Can any of this measured? No, not with a DVM or oscilloscope, but a resounding yes with the most sensitive measuring instrument of all: your ears! Snake-oil or science? Snake-oil. I say that because I don't want to encourage others to copy us but for you to try our products and decide for yourself. Where do you see the greatest benefit with respect to what is cryoed? Cables, electronics, etc. Speaker cables. Is there a limit to what can be cryoed? What I mean is, are the things that will not survive a freeze or perhaps have little if any benefit? The only thing we have had problems with is items that use hot glue; sometimes the hot glue does not go through the process, regardless of how slow you do it. For the most part the process if performed by competent persons, the process can actually be gentle. Are there any potential drawbacks to cryoing? Certainly. We have seen more than enough people treat this as a get rich quick scheme, who haphazardly treat components or material that they know very little about. We have had reports of people who have had their cables treated, come back cracked, crazed; not just to the dielectrics but also to the conductors. Is this long term or does something require a visit to the chamber after some time? This treatment is a one time permanent treatment, no re-visits are necessary. I would also like to point out that the process is not reversible. Where do you see the future of cryoing? We are working to treat the complete conductor chain from the microphones all the way through to achieve the most transparent sound yet.

Max Townshend Other interviews: Part 1 - An interview with Craig Goff of Kryophysics Part 2 - An interview with Charles Beresford of Cryogenics International

|

At

Townshend Audio we are also renowned for our ground-breaking

Glastonbury

loudspeakers designs, which currently are in Glastonbury III

guise incorporating built-in supertweeters. We also manufacture the Maximum

(read our review

At

Townshend Audio we are also renowned for our ground-breaking

Glastonbury

loudspeakers designs, which currently are in Glastonbury III

guise incorporating built-in supertweeters. We also manufacture the Maximum

(read our review

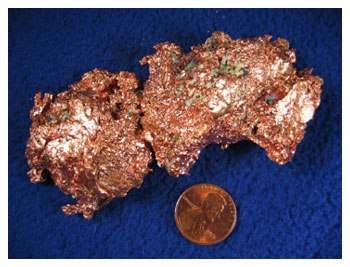

The treatment

is in effect a super annealing process equivalent to many years of "burning in". Electron microscope analysis has shown that the copper oxide at the crystal

boundaries has been forced into the body of the pure copper resulting in a

continuous copper conduction path. Further, the copper is measurably much softer

and much more malleable, a feature which is immediately apparent when handling

the material. This has an unfortunate side effect in that the copper is so soft

it can be very easily deformed, thus the cables must be handled with great care

to prevent damage.

The treatment

is in effect a super annealing process equivalent to many years of "burning in". Electron microscope analysis has shown that the copper oxide at the crystal

boundaries has been forced into the body of the pure copper resulting in a

continuous copper conduction path. Further, the copper is measurably much softer

and much more malleable, a feature which is immediately apparent when handling

the material. This has an unfortunate side effect in that the copper is so soft

it can be very easily deformed, thus the cables must be handled with great care

to prevent damage.